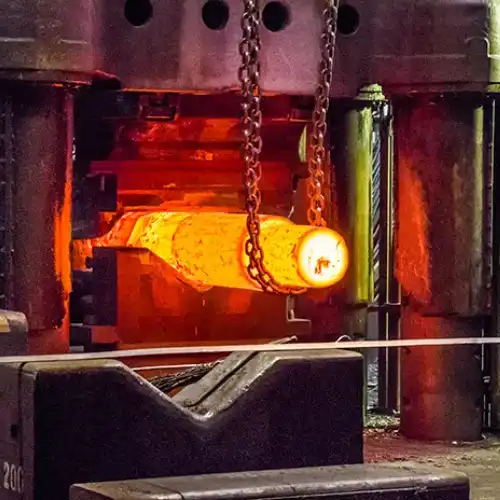

Transform Your Metal Production with Align MFG's Forging Services

In the dynamic world of metal production, Align MFG stands at the forefront of forging services. Our expertise in forging, honed over more than ten years, positions us as a pivotal manufacturer in transforming metal production

Why Choose Align MFG for Your Forging Needs?

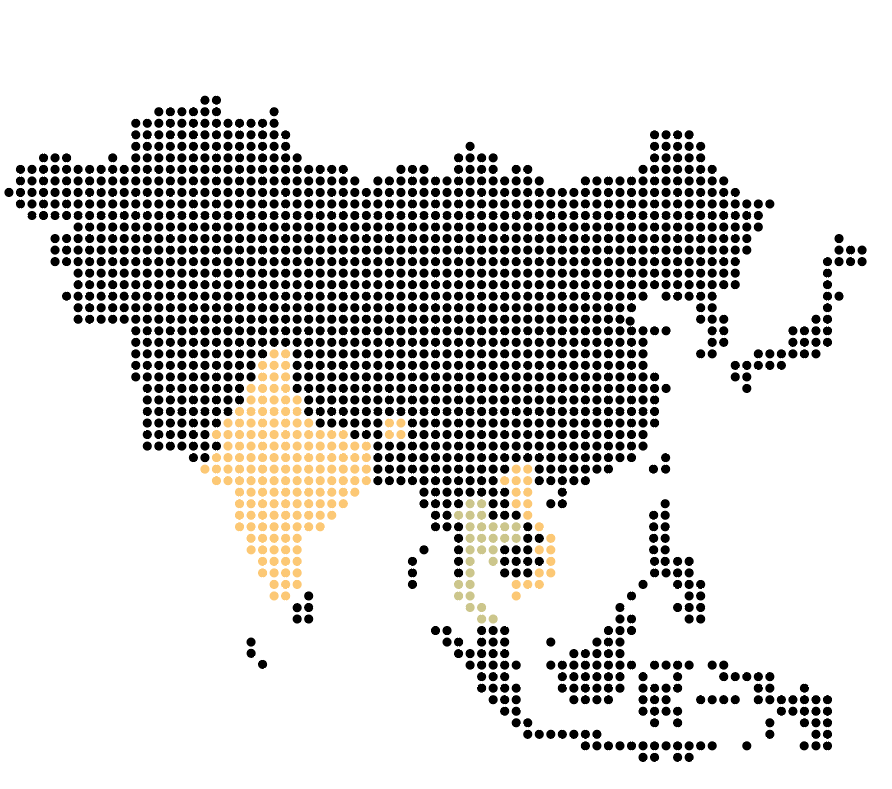

Expertise Across Borders

With factories in Thailand, Vietnam, India, and the United States, we bring global expertise and local understanding to your projects.

Customization and Flexibility

Whether it's a unique prototype or a large-scale production, we tailor our services to meet your needs.

Quality Assurance

Our commitment to quality and precision ensures that every component we forge stands the test of time and function.

Industrial Expertise

Our depth of knowledge in various industrial applications, from oil and gas to construction and beyond, allows us to provide solutions that are highly relevant and efficient for specific industry needs.

Our Services

Precision and Quality in Thailand, Vietnam, and India

At Align MFG, we specialize in elevating your metal production through forging techniques. Whether you're looking for intricate precision parts or large, customized components, our expertise in both closed die and open die forging guarantees results that meet your exact design specifications no matter where your project is based, including in the USA.

FAQ

At Align Manufacturing, we're always eager to hear from you. Whether you have a query, require a specialised component, or simply want to understand more about our intricate sourcing processes, don't hesitate to reach out. Allow us to guide you along your journey towards exceptional product sourcing and engineering. Your successful project is just a message away.