Align MFG stands at the forefront of sand casting processes,

manufacturing solutions across multiple regions, including the United States, Vietnam, India, and Thailand. While this page outlines our general sand casting capabilities, those specifically interested in sand casting in Thailand can explore our dedicated Thailand sand casting operations for local expertise, production facilities, and region-specific support.

We specialise in a wide range of materials and project sizes, from precision components to large-scale castings, supported by decades of engineering experience and consistent quality control across all markets.

Our Capabilities

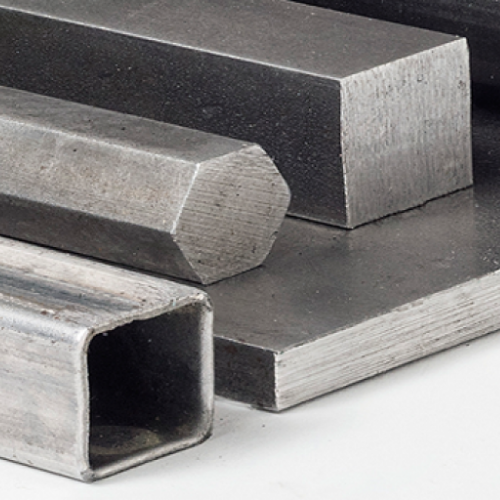

Grey and Ductile (SG) Iron

Utilizing these robust materials, we manufacture components that are known for their strength and durability, perfect for heavy-duty applications in American and global industries.

Stainless Steel

Our expertise in stainless steel casting results in parts that offer exceptional corrosion resistance and longevity, meeting the high standards of US-based industries.

Aluminum

Ideal for applications requiring lightweight strength, our aluminum castings are both resilient and versatile.

Carbon Steel

We provide carbon steel solutions for those seeking a balance between durability, performance, and cost-effectiveness.

Our Process

- Large pipe fittings: elbows, Ts, connectors, etc.

- Equipment housings

- Wind power fittings & housings

- Off-road equipment parts

- Large parts for road trailers

- Heavy machine bases and tables

And much more

Our Manufacturing Hubs Across Vietnam, India, Thailand and the United States of America

Each of our facilities is equipped with the appropriate manufacturing technologies and engineering capabilities, ready to fulfill your project needs.

Specializing in large-scale productions, our Thailand facility is the hub for intricate sand casting projects.

Known for its rapid turnaround times, the Vietnam facility excels in both small and large batch productions.

Our India location combines cost-effectiveness with high-quality production, suitable for a wide range of sand casting applications.

USA Facility:

Our USA headquarters in Arroyo Grande, California, supervises all international operations, ensuring compliance with American quality standards.

Why Choose Align MFG

for Your Sand Casting Solution?

Unmatched Expertise

Our team, with years of experience in metal production across the United States and abroad, ensures that your project is in capable hands.

Custom Sand Casting

We specialize in delivering high-quality machined castings tailored to meet your specific needs. Whether you require custom castings or large-scale production, we ensures that you receive durable and reliable products.

On-Time Delivery

We recognize the importance of deadlines and strive to deliver your project on schedule.

Cost-Effective Solutions

Align MFG is dedicated to providing the best value for your investment without compromising on quality.

FAQ

Submit Your RFQ Today

Do you have a specific sand casting project in mind? Send us your RFQ today to understand how Align MFG, with its US-based expertise, can effectively realize your specific manufacturing needs. We're here to discuss your requirements and offer tailored solutions that align with your project specifications, budget, and timeline.