What is CNC Machining?

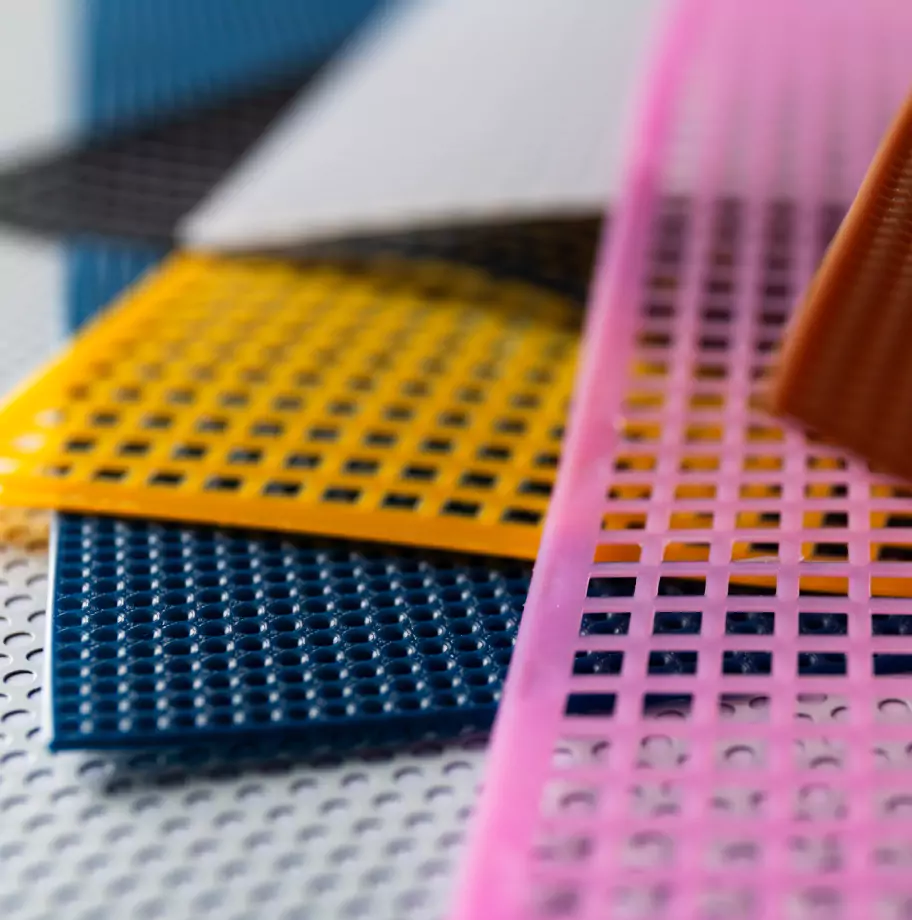

CNC (Computer Numerical Control) machining is an automated manufacturing process that uses programmed control systems to precisely machine parts from various materials, such as metals, plastics, and composites. It's ideal for creating both prototypes and full-scale production parts.

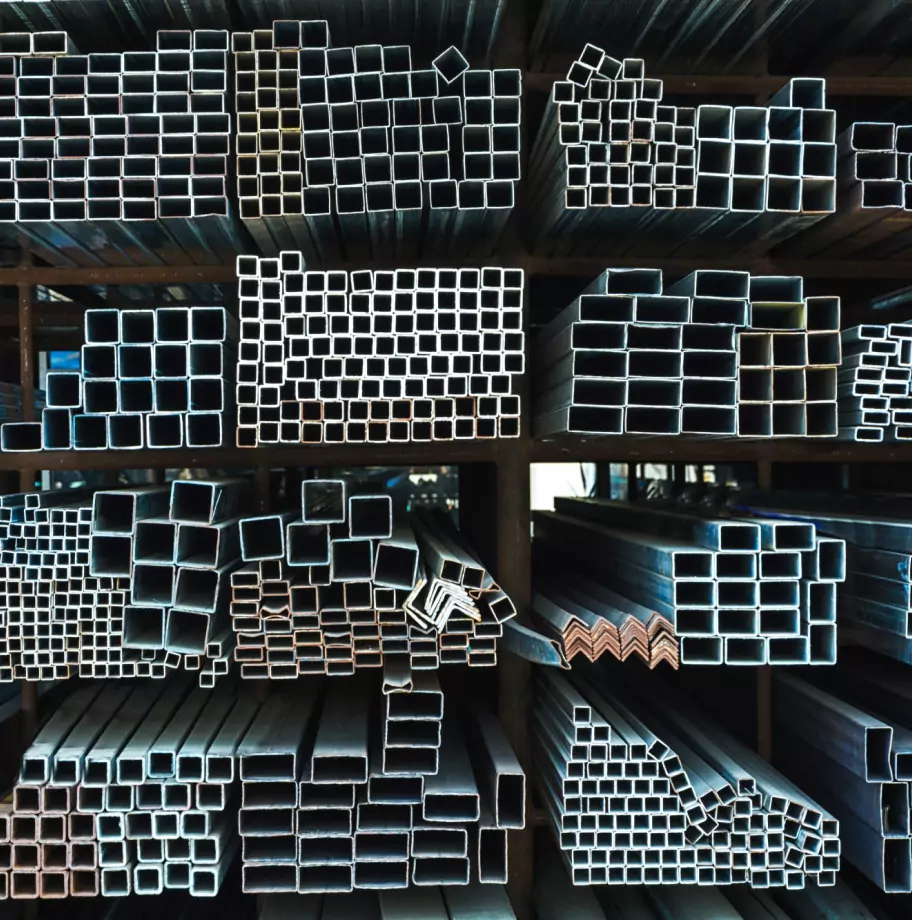

Fabrication involves cutting, bending, welding and assembling materials to create complex metal structures, often integrated with CNC machining for precision. At Align Manufacturing, our fabrication services ensure accuracy and quality across various projects.

Benefits of CNC Machining

Key Capabilities

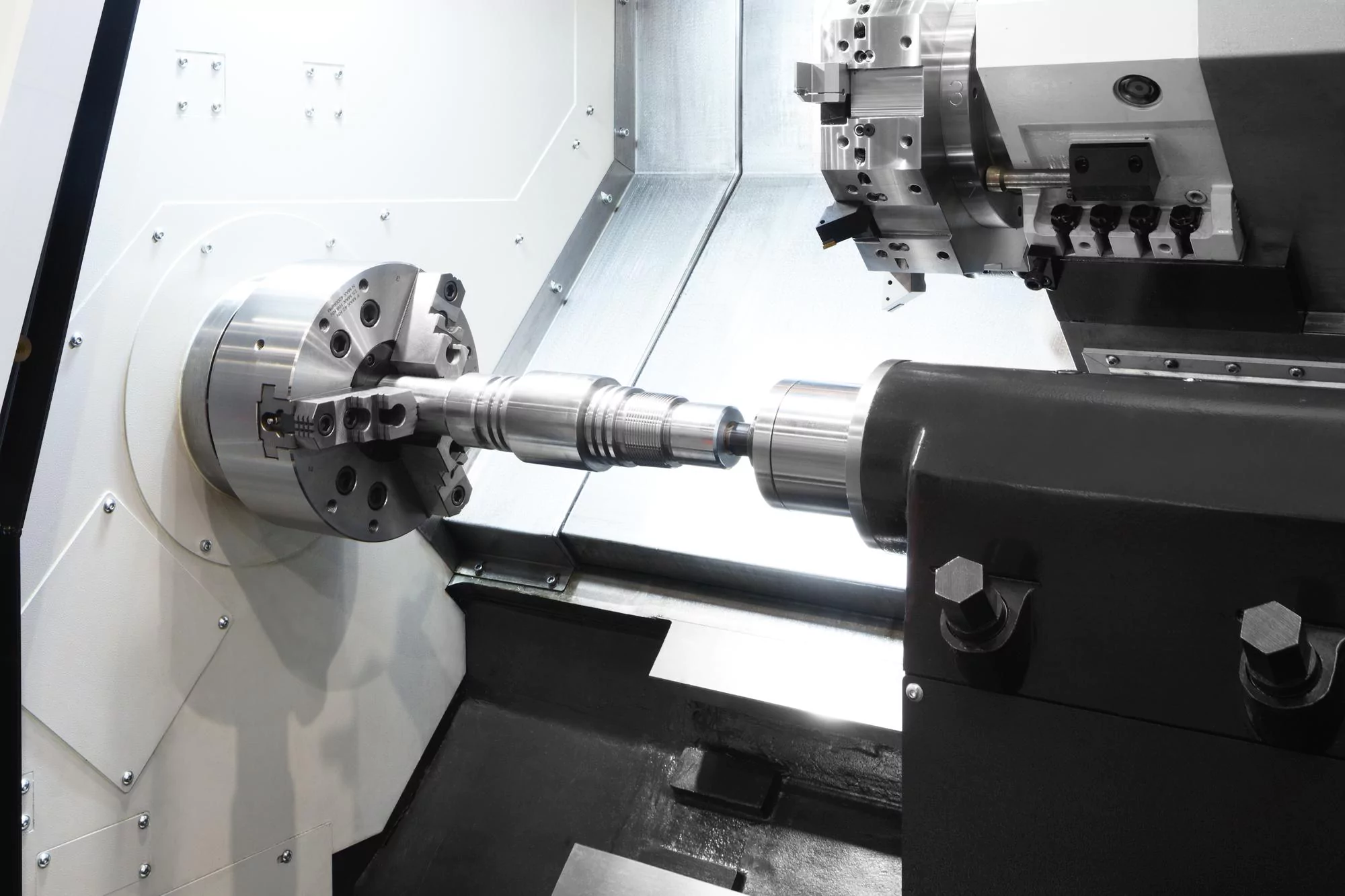

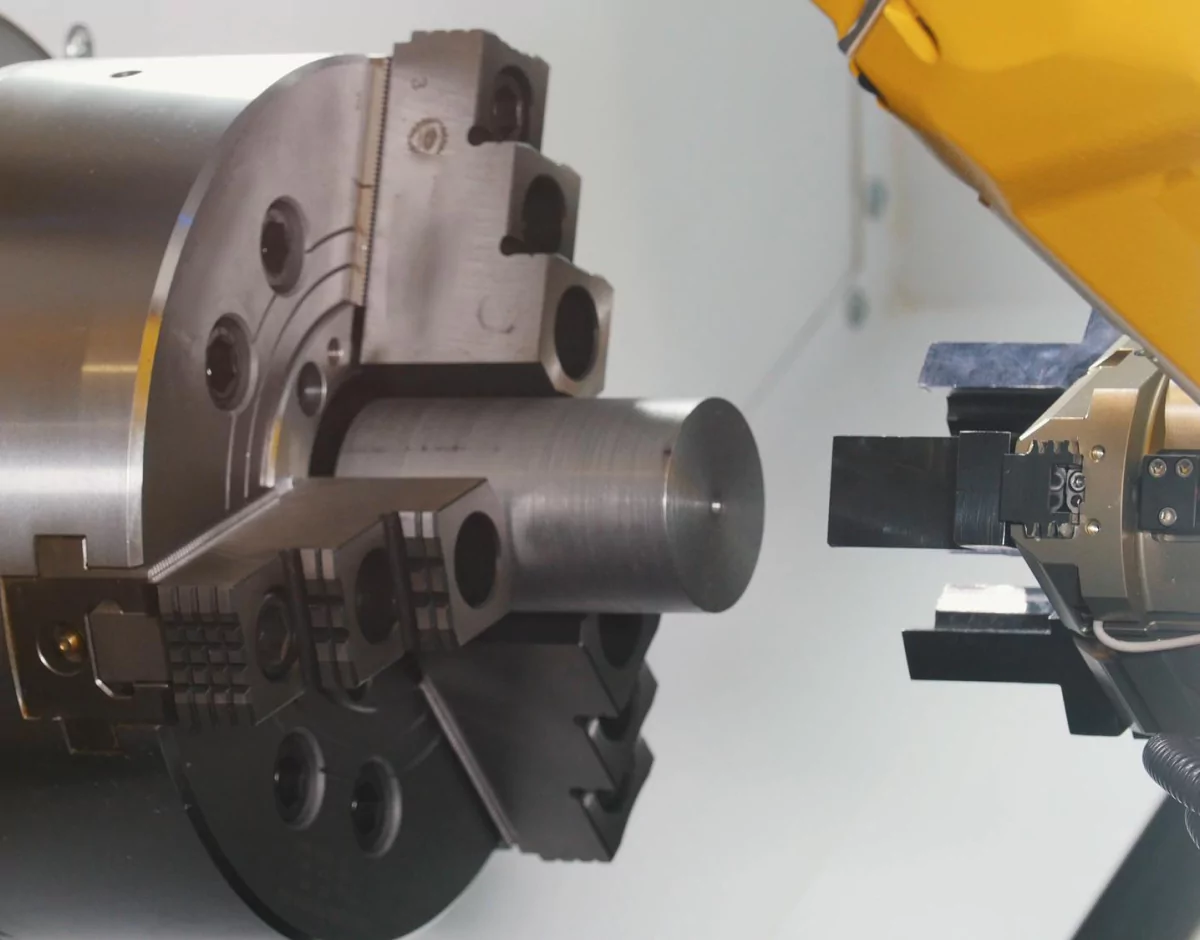

- 3-Axis, 4-Axis, and 5-Axis Machining: Handles complex geometries and multidimensional machining.

- Turning and Milling: Versatile manufacturing for both cylindrical and non-cylindrical parts.

- Rapid Prototyping: Speed up your product development with quick turnaround times.

- Custom Parts Manufacturing: Tailored solutions for unique designs.

- High-Volume Production: Scalable services to meet large production needs.

Our CNC Machining Process

- Design & Engineering Assistance: Get expert guidance on part design and material selection.

- Material Selection: Choose the right material for your application based on function and cost.

- Machining & Programming: Precise programming ensures high-quality production.

- Quality Assurance & Inspections: Strict quality control for each part.

- Delivery & Post-Processing: Options for finishing and delivery tailored to your needs.

Industries Utilizing CNC Machining

Aerospace

High-precision components that meet strict safety standards

Automotive

Custom parts for engines, transmissions, and body panels

Medical Devices

Precision-machined parts that comply with health regulations

Construction

CNC machining produces a variety of durable structural components using a range of materials, including metals and alloys

Electronics

Custom enclosures and parts for electronics manufacturing

Defense and Military

Durable parts designed to meet military specifications

Consumer Goods

Rapid production of durable and functional consumer products

Why Choose Us for CNC Machining?

- Experienced Engineers: Skilled team ensuring precision in every job.

- Competitive Pricing: High-quality service at cost-effective rates.

- Quick Turnaround Times: Speed and efficiency to meet your project deadlines.

- Commitment to Quality: We focus on delivering excellence in every project.

- Supply Chain Diversification: With factories in Thailand, Vietnam, India,we offer a strategic alternative to sourcing from China, providing our clients with cost-effective manufacturing solutions.

We're a dedicated team of local professionals passionately committed to fueling your project's success. Our team is dedicated to maintaining a keen eye for detail in every aspect of the process, from design to delivery. Simultaneously, we prioritize clear, consistent communication with you to ensure that your vision and requirements are fully understood and met.