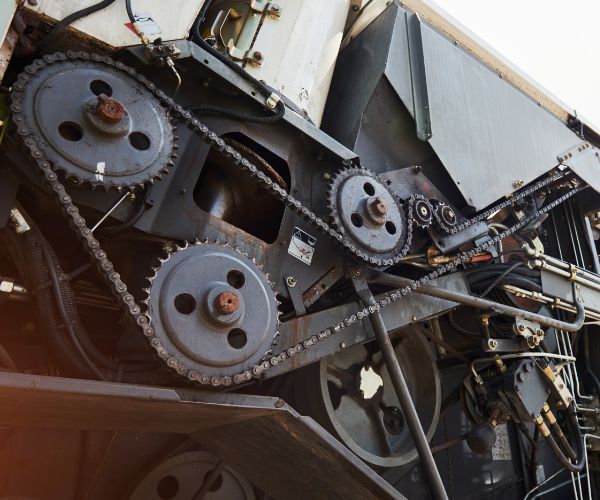

Gears are integral to the smooth operation of trucks and trailers, playing a vital role in transmission and engine performance. Align MFG, with its expertise in the trucking industry, specializes in manufacturing high-quality gears that are essential for the efficient functioning of these vehicles.

- Worm Gears: Used in geared motors, worm gears provide precise speed control and high torque for managing heavy trailer loads.

- Bevel Gears: Essential for drive shafts, bevel gears enable angular power transmission crucial for truck differential mechanisms.

- Helical Gears: Durable and quiet, helical gears ensure efficient power transmission in geared motors and drive shafts for long-haul trucking.

- Internal Gears: Found in planetary gear setups, internal gears offer high torque in a compact design, suitable for trucks' space-limited applications.

- Spur Gears: Common in truck mechanisms, spur gears handle linear motion and high speeds effectively in drive shafts and geared motors.

Optimizing Truck and Trailers Gears

The production of gears for the trucking industry is laden with challenges such as ensuring wear resistance, managing heavy load capacities, and maintaining high precision.

These challenges are crucial as they directly impact the longevity and efficiency of the vehicles. Align MFG addresses these issues head-on, ensuring every gear meets the industry's stringent demands.

Align MFG's Gear Production Techniques

Our manufacturing processes set us apart in the gear production domain. We utilize durable metals such as high-grade steel and employ technologies to ensure each gear is manufactured with utmost precision. This not only enhances gear longevity but also improves overall vehicle performance. (add links to main process page)

Custom Gear Solutions for Diverse Trucking Needs

Understanding that each truck and trailer has unique requirements, Align MFG offers custom gear solutions. Whether it's adapting to different models or specific load requirements, our gears are tailored to meet the diverse needs of the trucking industry, ensuring optimal compatibility and performance.

Quality, Precision, and Efficiency in Gear Manufacturing

Quality Control Measures

Our gears are subjected to rigorous quality control measures, including the use of the AQL (Accepted Quality Level) method. This statistical quality checking approach ensures that our gears consistently exceed industry standards for durability and performance.

Adherence to Tight Tolerances

Our manufacturing process is finely tuned to meet very tight tolerances as specified in the drawings. This precision is crucial for ensuring that each gear fits correctly with other parts, maintaining the integrity and functionality of the truck and trailer mechanisms.

High Packing Standards

Recognizing the potential for damage during shipping, we place a strong emphasis on packing standards. Our thorough and careful packing procedures ensure that the gears are well-protected and remain intact throughout their journey, minimizing the risk of damage due to movement during transit.

Supply Chain and Logistics Expertise

Our strategic location in Sout East Asia such as India, Thailand and Vietnam enhances our supply chain efficiency, particularly beneficial for multi-component orders. This geographical advantage ensures timely delivery of gears across the globe, reducing lead times and improving the overall efficiency of our clients’ operations.

Get in Touch

For precision-engineered gears tailored to the demanding needs of the trucking industry, choose Align MFG.

With our extensive network across Vietnam, India, and Thailand, we deliver metal components that align with your project specifications and budget, ensuring on-time delivery of high-quality components.

Experience seamless communication and a cost-effective alternative to Chinese supply chains. Contact Align MFG today for a consultation or to request a quote, and elevate the efficiency of your truck and trailer operations.