Posts by Casey Ross

Pouring Metal: From Liquid to Solid

The transformation of molten metal into a solid form is both a critical and captivating phase in the sand casting process. This stage is where the preparatory work of pattern making and mold preparation converges with the alchemy of metalwork. Let’s explore the intricacies of pouring metal, focusing on preparation, techniques, and considerations crucial to achieving a defect-free casting.

Preparing for Pouring: Checking Metal Temperature and Mold Readiness

Before the molten metal is introduced into the mold, two pivotal checks must be performed: ensuring the metal is at the correct temperature and confirming the mold’s readiness.

- Metal Temperature: The temperature of the molten metal is crucial for a successful pour. If the metal is too hot, it may cause unwanted reactions with the mold material or result in defects like gas porosity. If too cold, the metal might solidify before filling the entire mold cavity. Using a pyrometer, the temperature is precisely measured to align with the specific metal’s ideal pouring range.Use pyrometers to ensure optimal pouring temperature (700-750°C for aluminum, 1,200-1,400°C for iron)

- Mold Inspection: Check for moisture, contaminants, and structural integrity

- Mold Readiness: The mold must be dry and free of contaminants. Moisture can cause steam explosions, while dirt or debris can lead to surface defects in the final casting. The mold’s integrity is inspected to ensure it can withstand the thermal shock of the molten metal without collapsing or cracking.

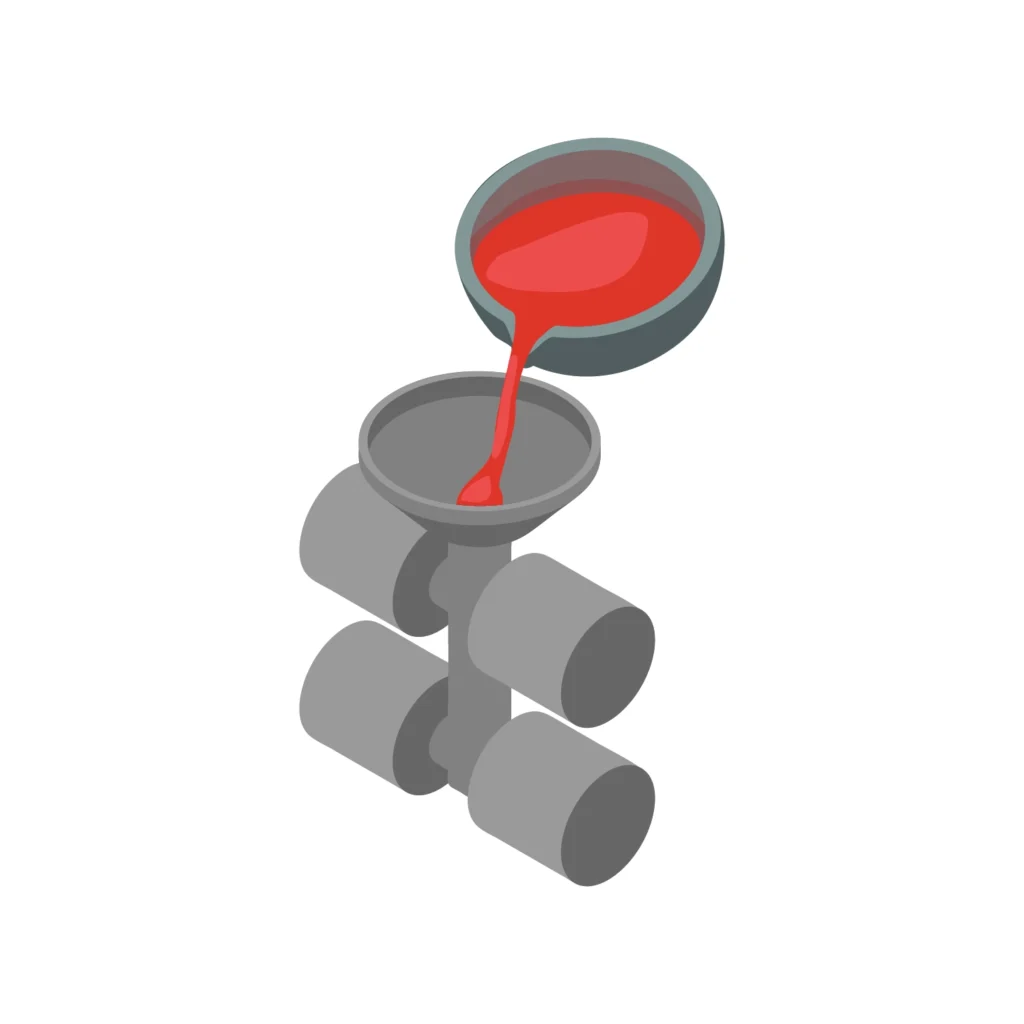

Techniques and Tools for Pouring: Ladles, Pouring Basins, Gates, and Runners

The actual pouring of the metal requires skill and the right tools to direct the molten metal from the furnace to the mold cavity efficiently.

- Ladles: These are the primary tools for transporting and pouring molten metal. They range from simple hand-held devices for small quantities to mechanically operated ladles for large volumes, ensuring precise control over the pour.

- Pouring Basins: A funnel-shaped reservoir at the top of the mold that receives the molten metal from the ladle. It helps in minimizing splashing and directs the flow into the mold’s gating system.

- Gates and Runners: These are channels carved into the sand mold that guide the molten metal from the pouring basin to the mold cavity. Proper design of gates and runners is vital to control the flow speed and reduce turbulence.

Considerations to Avoid Defects: Turbulence, Air Entrapment, and Temperature Control

The way metal is poured can significantly impact the quality of the casting. Here are key considerations to mitigate common defects:

- Turbulence: A gentle and controlled pour is essential to prevent the molten metal from splashing and creating turbulence as it enters the mold. Turbulence can lead to air entrapment and oxide formation, compromising the casting’s integrity.

- Air Entrapment: Strategic placement of vents in the mold allows gases to escape as the molten metal fills the cavity. Ensuring an uninterrupted flow of metal helps in minimizing air pockets or voids in the final casting.

- Temperature Control: Besides the initial temperature check, maintaining an optimal temperature gradient during the pour is crucial. Too rapid cooling can lead to cold shuts (where liquid metal streams don’t fuse properly), while too slow can cause shrinkage cavities as the metal solidifies.

Mold Coatings for Improved Casting Quality

Mold coatings enhance surface finish and reduce casting defects:

- Types of Coatings:

- Graphite-based coatings: For smoother surfaces.

- Zircon-based coatings: High thermal resistance for larger or complex molds.

- Applications: Applied as a wash or spray before pouring to create a non-reactive layer between molten metal and sand.

This reduces surface roughness and minimizes metal-sand reactions.

Metal Fluidity and Flow Analysis

The fluidity of molten metal determines how well it fills the mold cavity without defects.

- Factors Affecting Fluidity:

- Pouring temperature (higher improves flow but risks oxidation).

- Mold material and surface smoothness.

- Metal composition: Alloys behave differently in terms of viscosity.

- Flow Simulation Software: Modern software tools predict how molten metal will flow, ensuring optimal gating and riser design.

Automation and Technology in Melting and Pouring

Advancements in foundry technology have streamlined the melting and pouring stages, improving safety, precision, and efficiency.

Technologies Enhancing Melting and Pouring:

- Robotic Ladle Pouring: Ensures consistent and controlled pouring while reducing human error.

- IoT Sensors: Real-time temperature and quality monitoring optimize performance.

- Automated Furnace Controls: Maintain precise melting temperatures with minimal energy loss.

- Simulation Software: Predict and resolve defects before the casting process begins.

Automation reduces waste, enhances repeatability, and boosts productivity for modern foundries.

Mastering the pour is a delicate balance between art and science, requiring attention to detail, precision, and timing. When executed correctly, it culminates in the magical moment where molten metal begins its transformation into a solid, embodying the desired shape and properties embedded in the sand mold. This phase is not just about transferring metal from one container to another; it’s about ensuring the integrity, quality, and success of the casting through meticulous preparation and execution.

Melting the Metal: The Foundation of Sand Casting

Metalworking has its roots in smelting, the process of extracting metals from ores. Unlike melting, which reshapes pure metals or alloys, smelting involves chemically separating a metal from its natural mineral form. This process laid the foundation for modern metal casting techniques.

The Bloomery Process: The Birthplace of Metal Extraction

- The bloomery was the first furnace designed to smelt iron ore.

- How It Worked: Charcoal-fueled fires and forced air from bellows produced the intense heat needed to reduce iron ore into a spongy mass called a bloom.

- Key Result: The bloom was hammered to remove slag, yielding workable wrought iron. This primitive process shaped human history by enabling the creation of tools, weapons, and structures.

The Rise of Pig Iron through Advanced Smelting

- Smelting evolved with the invention of the blast furnace, which could sustain higher temperatures and produce pig iron—a crude form of iron with high carbon content.

- Why Pig Iron?: The name comes from the traditional casting setup, where molten iron was poured into molds resembling piglets suckling from a sow.

- Limitations: Pig iron was brittle due to its high carbon content but could be refined into steel, marking a major advancement in metallurgy.

Throughout history, advancements in metallurgy have driven technological progress. The Bronze and Iron Ages marked early breakthroughs, while the Industrial Revolution ushered in the Steel Age. A pivotal innovation was the Bessemer process, which introduced oxygen into molten steel, raising temperatures and accelerating production. This method revolutionized steel manufacturing, enabling the creation of modern infrastructure such as railways, engines, and large-scale construction projects.

Why Alloying Matters

The practice of mixing metals revolutionized metal casting by enhancing the properties of metals, making them stronger, more resistant to corrosion, and easier to work with. This transformative process remains essential in modern metallurgy.

Historical Alloying: The Bronze Age Breakthrough

- The first significant alloy was bronze, a mixture of copper and tin, marking the start of the Bronze Age.

- Impact: Stronger and more versatile than pure copper, bronze was used for weapons, tools, and sculptures, enabling societal and technological advances.

At the heart of sand casting for stainless steel lies the transformative process of melting metal, turning solid ingots or scraps into a fiery liquid form ready to take on a new identity. This stage is where raw materials are prepped to become intricate parts of machinery, beautiful sculptures, or essential everyday tools. Let’s explore the critical aspects of melting metal, from selecting the right type of metal to understanding the intricacies of the melting process and the final adjustments before the pour.

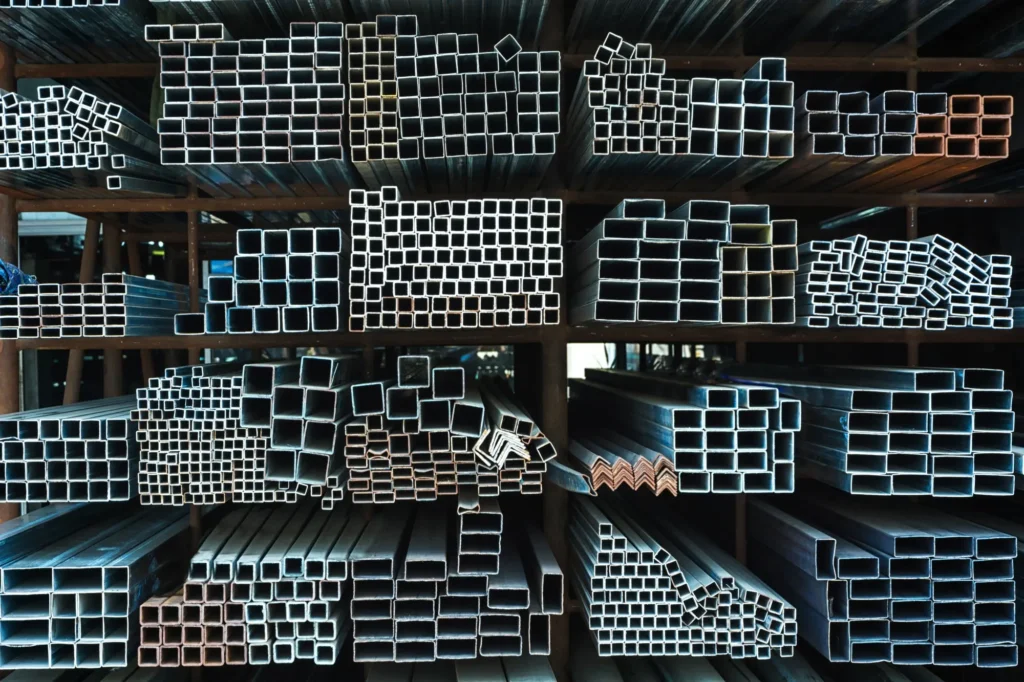

Overview of Metal Selection

The choice of metal is pivotal and depends on the desired properties of the final cast product. Each metal or alloy offers a unique combination of strength, ductility, corrosion resistance, and thermal conductivity. The most commonly used metals in sand casting include:

- Iron: Renowned for its strength and durability, iron is often used in automotive and machinery components.

- Aluminum: Known for its lightweight and corrosion resistance, aluminum is favored in aerospace and automotive industries.

- Bronze: Valued for its excellent corrosion resistance and aesthetic appeal, bronze is commonly used in sculptures and marine hardware.

The selection process involves considering the application’s requirements and balancing them with cost and material properties to choose the most suitable metal.

The Melting Process

Melting metal is a complex operation that demands precision and safety. The process varies depending on the metal, but the fundamentals remain the same. Here’s a breakdown:

- Furnaces Used: Different types of furnaces are employed based on the metal’s melting point and the volume of metal needed. Common furnaces include cupola furnaces for iron, electric arc furnaces for steel, and induction furnaces for a variety of metals. Each offers advantages in efficiency, temperature control, and environmental impact.

- Safety Measures: Melting metal involves extremely high temperatures, necessitating strict safety protocols to protect workers. Personal protective equipment (PPE), such as heat-resistant gloves, face shields, and aprons, are essential. Proper ventilation and training in handling molten metal are also critical to prevent accidents.

- Automated ladle systems to minimize manual handling.

- Use of advanced PPE (heat-resistant suits, insulated face shields).

Metal Melting Defects and Their Prevention

Metal melting is a precise process, but defects can arise if certain precautions are not taken. These defects can compromise the quality, strength, and appearance of the final casting.

Common Melting Defects:

- Gas Porosity: Caused by dissolved gases like hydrogen being trapped during solidification.

- Slag Inclusion: Non-metallic impurities mixed into the molten metal.

- Oxidation: Formation of oxide layers when molten metal reacts with oxygen.

- Cold Shuts: Premature solidification of metal due to improper pouring.

Prevention Methods:

- Degassing: Use inert gases like argon or nitrogen to remove dissolved gases.

- Fluxing: Add flux materials to absorb impurities and bring them to the surface for skimming.

- Controlled Pouring: Maintain proper pouring temperature and reduce turbulence.

- Clean Charge Materials: Pre-cleaning ingots and scrap reduces impurities.

Types of Melting Furnaces and Their Applications

- Cupola Furnace:

- Description: A traditional furnace used mainly for melting cast iron.

- How It Works: Coke is used as fuel to reach high temperatures. Metal is charged at the top, while slag is removed from the bottom.

- Advantages: Economical, ideal for large volumes of iron casting.

- Induction Furnace:

- Description: Uses electromagnetic induction to melt metals.

- Applications: Melting ferrous and non-ferrous metals for precision casting.

- Advantages: Energy-efficient, precise temperature control, and low environmental impact.

- Electric Arc Furnace (EAF):

- Description: Used for steel production. Electrodes generate heat to melt scrap metal.

- Advantages: Suitable for recycling scrap metal and producing high-quality alloys.

- Crucible Furnace:

- Description: Small-scale furnace where metal is melted in a crucible.

- Applications: Ideal for smaller volumes, prototyping, or precious metals like bronze.

Preheating and Maintaining Furnace Lining

Furnace lining plays a vital role in maintaining temperature consistency and extending furnace life.

- Preheating: Linings must be preheated gradually to avoid thermal shock, which can cause cracks or uneven heat distribution.

- Maintenance: Regular checks for erosion, wear, or slag buildup are essential.

- Replacement: Use high-quality refractory materials to withstand molten metal temperatures and avoid contamination.

- Temperature Control: Precise temperature control is crucial for achieving the desired metal properties. Each metal and alloy has an optimal pouring temperature to ensure it fills the mold cavity correctly without premature solidification or creating defects.

Factors Influencing the Quality of Molten Metal

- Cleanliness of Charge Materials:

- Impurities in ingots or scrap can affect the quality of the final casting. Pre-cleaning the charge material is essential.

- Proper Alloying Ratios:

- Ensuring the correct ratio of base metal and alloying elements to achieve desired strength, corrosion resistance, and machinability.

- Degassing Methods:

- Techniques like inert gas injection (e.g., argon or nitrogen) to eliminate gas porosity.

- Fluxing Agents:

- Chemicals added to molten metal to remove non-metallic inclusions or slag, improving surface finish and reducing defects.

Measuring and Monitoring Melt Quality

Quality assurance during melting ensures the final casting meets required specifications.

- Chemical Analysis: Use spectrometers to measure alloy composition in real time.

- Temperature Sensors: Infrared thermometers and thermocouples monitor precise melting and pouring temperatures.

- Density Testing: Check for gas porosity using density measurements.

These measures reduce defects and ensure molten metal meets performance standards.

Alloying and Treatment

The composition of the metal significantly influences the properties of the final casting. Adjustments can be made during the melting process to achieve the desired characteristics:

- Alloying: Adding specific elements to the base metal can enhance its strength, ductility, or corrosion resistance. For instance, adding chromium and nickel to steel improves its stainless properties, while adding silicon to aluminum can increase its casting ability.

- Treatment: Metal treatments, such as degassing or fluxing, are often performed to improve the quality of the melt. Degassing removes dissolved gases that could cause porosity in the casting, and fluxing cleans the metal by removing impurities to the surface, where they can be skimmed off.

Modern Alloying Techniques

- Micro-Alloying: Adding trace elements such as vanadium or niobium enhances hardness and corrosion resistance.

- Steel Production: Combining iron with carbon produces steel, known for its strength and flexibility. Stainless steel, with added chromium and nickel, resists corrosion and oxidation.

- Aluminum Alloys: Adding magnesium, silicon, or zinc creates lightweight, strong alloys used in aerospace and automotive industries.

The Alloying Process: How It’s Done

- Melting and Blending: Metals are heated in a furnace until molten, allowing for even mixing.

- Chemical Adjustments: Elements are added in precise amounts based on desired mechanical and chemical properties.

- Solidification and Casting: Once mixed, the alloy is poured into molds to form ingots or complex components

Heat Treatments Post-Casting:

After pouring and cooling, alloys can be heat-treated to refine grain structures:

- Annealing: Reduces internal stress and improves ductility.

- Tempering: Enhances toughness by reducing brittleness.

- Quenching: Rapid cooling to increase hardness.

Mold Coatings for Improved Casting Quality

Mold coatings enhance surface finish and reduce casting defects:

- Types of Coatings:

- Graphite-based coatings: For smoother surfaces.

- Zircon-based coatings: High thermal resistance for larger or complex molds.

- Applications: Applied as a wash or spray before pouring to create a non-reactive layer between molten metal and sand.

This reduces surface roughness and minimizes metal-sand reactions.

Environmental and Sustainability Considerations

- Recycling Scrap Metal:

- Importance of using recycled materials to reduce production costs and environmental impact.

- Energy Efficiency:

- Comparing energy consumption of different furnaces (induction vs. cupola).

- Emission Control:

- Technologies like fume extraction systems and slag recycling.

Comparison of Sand Casting Melting with Other Processes

Melting and pouring techniques vary across different casting processes. Here’s how sand casting compares:

| Feature | Sand Casting | Investment Casting | Die Casting |

| Precision | Moderate | High | Very High |

| Cost | Low to moderate | Moderate to high | High |

| Volume | Low to high (flexible) | Low to medium | High (mass production) |

| Material Variety | Wide range of metals | Mostly non-ferrous metals | Limited (mainly aluminum/zinc) |

Sand casting is versatile and cost-effective, making it ideal for both small and large-scale production runs.

By carefully selecting the metal, mastering the melting process, and fine-tuning the composition, casters ensure the molten metal is perfectly primed for its transformation into a solid, new form within the sand mold. This pivotal phase not only shapes the metal’s destiny but also reflects the profound skill and understanding behind the ancient craft of sand casting.

Mold Preparation: Crafting the Cavity

After the meticulous creation of a pattern, the next step in the sand casting process is preparing the mold—a critical phase where the sand meets the design to create a negative space for the molten metal. This stage is all about precision and technique, ensuring that the final cast will be as close to the original design as possible. Let’s explore the intricacies of mold preparation, from the selection of sand to the creation of cores for internal cavities.

Technical Casting Terminology

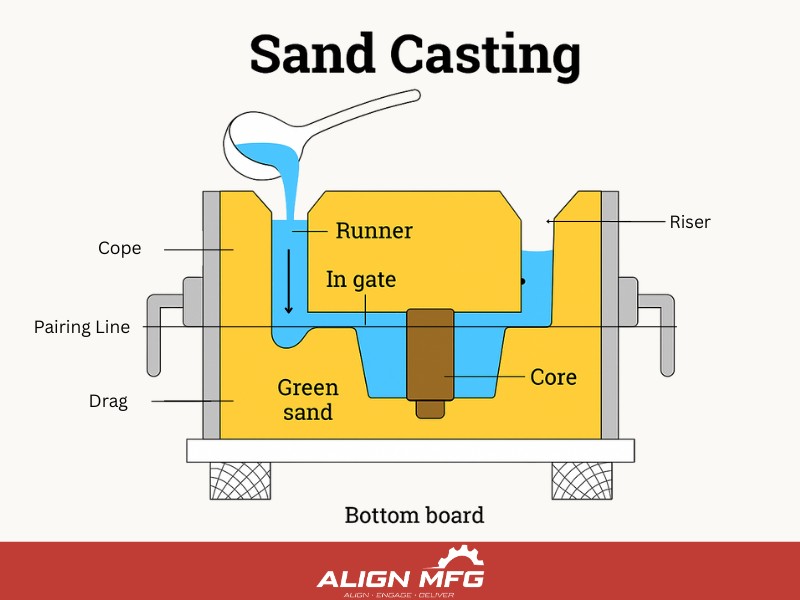

In sand casting, several technical terms define the mold-making and casting process. A casting mold is a cavity created from packed sand that forms the shape of the metal part to be cast. It consists of two main sections: the cope (top half) and drag (bottom half), which together enclose the mold cavity. Ramming refers to compacting sand tightly around the pattern to create a firm mold, ensuring the metal fills all details accurately. Swinging typically involves moving the mold or pattern into place during preparation or aligning mold sections before the pour. Understanding these terms helps explain the precise, detail-oriented nature of the sand casting process, ensuring quality and accuracy in the final product.

Introduction to Sand Types and Properties

The foundation of a good mold is the sand used to make it. The choice of sand significantly affects the mold’s quality, impacting the surface finish, dimensional accuracy, and strength of the final casting. Two of the most common types of sand used in casting are:

- Green Sand: A mixture of silica sand, clay (binder), and water, green sand is called so not because of its color but because it is ‘wet’ or ‘fresh’ when the mold is made. It’s reusable and suitable for a wide range of casting metals and sizes.

- Resin Sand: Enhanced with a resin binder instead of clay, resin sand provides higher strength and better dimensional accuracy. It’s often used for larger castings or when higher precision is required.

Each type of sand has its own set of properties—like permeability, cohesiveness, and thermal stability—that make it suitable for specific casting applications.

Types of Molds in Metal Casting

While sand casting is the most common method, understanding the full spectrum of mold types helps in selecting the right process for specific applications: -

Shell Molding: A specialized process using resin-coated sand that forms a thin, hard shell when heated. This method offers better dimensional accuracy than traditional sand casting and is ideal for smaller parts requiring precise details.

Investment Casting (Lost-Wax): Creates extremely accurate molds using a wax pattern coated with ceramic material. Once the ceramic hardens, the wax is melted out, leaving a precise cavity. -

For more information on what investment casting is and its processes check out our blog: https://alignmfg.co/all-about-investment-casting-process-materials-and-uses/

Full Mold/Foam Process: Uses expendable foam patterns that vaporize when molten metal is poured, offering unique advantages for complex geometries.

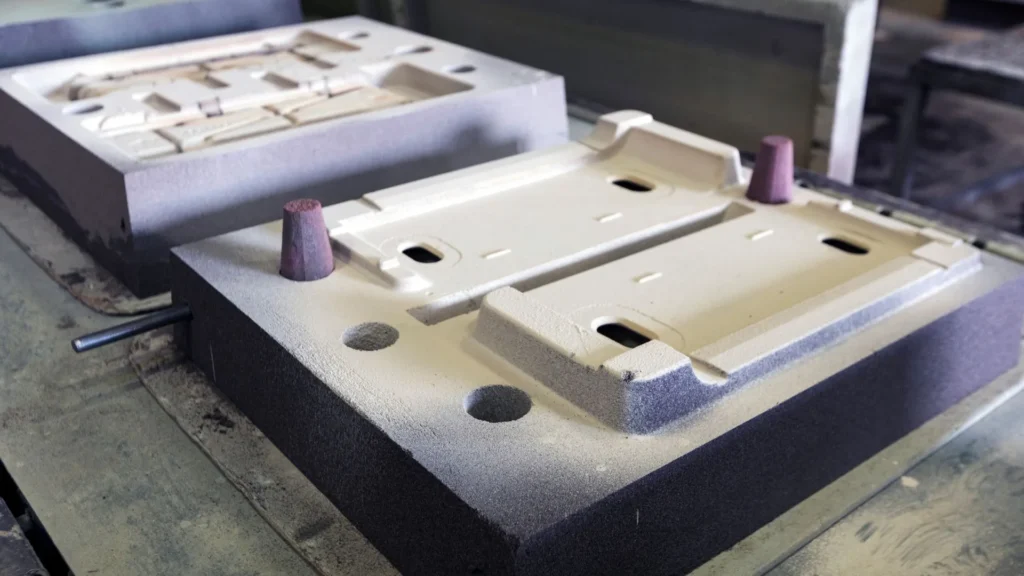

Mold Components: Cope and Drag

The sand mold consists of two primary parts: the cope (the top half) and the drag (the bottom half). These terms aren’t just jargon but signify the functionality of each part of the mold. The cope and drag work together to form the entire mold cavity, where the drag supports the weight and the cope contains the risers and gating system necessary for the metal to enter and gases to escape.

Critical Mold Features and Their Functions

A successful mold incorporates several essential elements: -

Gating System: The network of channels that guide molten metal into the mold cavity:

Pouring basin: Controls initial metal entry

Sprue: Main vertical channel

Runners: Horizontal distribution channels

Gates: Final entry points into the casting cavity

Risers: Reservoirs that feed additional metal to compensate for shrinkage during solidification

Open risers: Visible from outside the mold

Blind risers: Completely enclosed within the mold

- Vents: Strategic openings that allow gases to escape during pouring

The Process of Packing Sand Around the Pattern: Ramming and Compaction

Creating a mold starts with placing the pattern in a mold box (flask) and then packing it with sand. The key to this step is ensuring the sand is compacted tightly around the pattern to capture every detail:

- Filling: The flask is filled with sand around the pattern. Special attention is paid to ensure the sand gets into all the crevices and details of the pattern.

- Ramming: The sand is compacted, or “rammed,” around the pattern, usually with a pneumatic rammer, to ensure it’s firm and there are no gaps.

- Removal: Once the sand has been sufficiently compacted, the pattern is carefully removed, leaving a cavity in the shape of the part to be cast.

This process might be repeated for both the cope and drag sections of the mold, depending on the complexity of the casting.

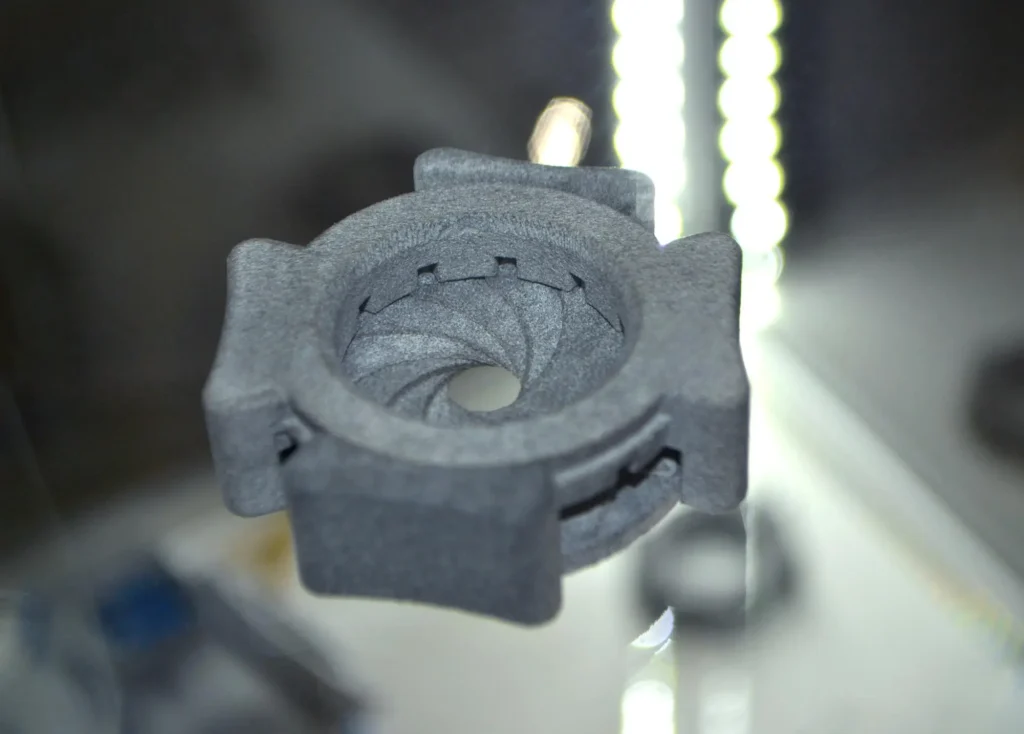

Core Making: Materials, Making, and Placement for Internal Cavities

For castings that require internal cavities or complex geometries, cores are used. Cores are made from similar materials as the mold but are often strengthened with binders or other additives to maintain their shape under the pressure of molten metal:

- Materials: Core sand is selected based on the casting material and the required surface finish and strength of the core.

- Making: Cores are formed using a core box, similar to the pattern in mold making. The sand is packed into the core box and then hardened, usually with heat or chemical binders.

- Placement: Once hardened, the core is placed into the mold cavity before the mold is closed. It’s positioned so that, once the metal is poured, it will fill around the core, creating the desired internal structure

Quality Control in Mold Preparation

Ensuring mold quality is crucial for successful casting: -

Surface Finish Considerations:

- Sand grain size selection based on desired finish

- Proper compaction techniques to prevent surface defects

- Mold coating applications for improved finish

Common Defects and Prevention:

- Sand inclusions: Prevented through proper ramming

- Mold erosion: Controlled through optimal pouring speed

- Gas porosity: Addressed with adequate venting

Dimensional Control:

- Measuring and maintaining proper mold wall thickness

- Verifying core alignment and position

- Checking parting line accuracy

The Foundation of Successful Casting

Mold preparation stands as the cornerstone of quality metal casting, where every detail matters—from the initial selection of molding materials to the final quality checks. Whether using traditional green sand methods or advanced techniques like shell molding, success lies in the careful attention to each component: proper sand composition, precise pattern

placement, strategic gating systems, and accurate core positioning.

This meticulous approach to mold preparation not only ensures dimensional accuracy and surface quality but also sets the stage for the dramatic transformation of molten metal into finished castings that meet exact specifications. As foundry technology continues to evolve, these fundamental principles of mold preparation remain essential to the art and science of metal casting.

Choosing the right casting method requires careful evaluation of your project’s specifications. While ferrous metals are typically cast using expendable molds due to their high melting points, non-ferrous metals offer more versatility with processes like permanent or semi-permanent mold casting. Each project is unique, so understanding factors like part size, wall thickness, weight, and surface finish is essential for selecting the most efficient and cost-effective casting technique. Collaborating with an experienced manufacturing partner ensures precision, quality, and optimized production costs. Contact Align Manufacturing today to discuss your casting needs and find the perfect solution for your next project.

FAQ

Related Blogs

Sorry, we couldn't find any posts. Please try a different search.

The Design Phase: Pattern Creation

The journey of every sand casting begins with a blueprint, not on paper, but in the form of a pattern. This initial step is crucial, as the pattern is the mirror image of the final casting, embodying every detail of the desired outcome. Let’s delve into the nuances of pattern creation, a process that marries precision with creativity, setting the stage for everything that follows in the sand casting saga.

Pattern Types and Classifications

Understanding the various types of patterns is crucial for successful sand casting. Each type serves specific purposes and production needs:

- Flat Back Patterns: These patterns are pressed into the drag (bottom part) of the sand mold, with an unmolded cope (top half) clamped on top. They're ideal for simpler designs with one flat surface.

- Split Patterns: Designed in multiple parts, these patterns allow for more complex geometries. Each section can be impressed into different parts of the mold and removed without damaging the cavity.

- Match Plate Patterns: These patterns are mounted on plates, enabling simultaneous pressing of both mold halves. They're particularly efficient for high-volume production environments.

- Sweep Patterns: Using a rotating blade with a shaped profile, these patterns carve the sand around an axis, similar to a lathe creating negative space. They're perfect for symmetrical, circular castings.

- Gated vs. Loose Patterns: While loose patterns replicate just the final object, gated patterns include the metal feeding system within the pattern itself, reducing the need for hand-cut channels.

Segmented Patterns: For large or complex castings, segmented patterns are constructed in sections for easier handling and assembly. This approach simplifies transport, reduces weight, and enhances pattern durability, making it ideal for producing oversized components.

- Core Prints: These are projections on the pattern that create recesses in the mold to position and support cores accurately, ensuring proper formation of internal cavities in the casting.

Materials Used for Patterns and Their Selection Criteria

Patterns can be made from various materials, each chosen based on specific requirements of the casting process, the complexity of the design, and the number of casts to be produced. Common materials include:

- Wood: Traditional and widely used due to its ease of machining and cost-effectiveness. Best suited for prototypes and small production runs.

- Metal: Preferred for high-volume production due to its durability. Metals like aluminum and cast iron are common choices.

- Plastic: Offers excellent surface finish and dimensional stability. Used in both prototype and production patterns.

- Foam: Utilized in lost foam casting processes, foam patterns are vaporized upon contact with molten metal, allowing for intricate designs.

The selection criteria often hinge on factors such as the expected lifespan of the pattern, detail complexity, and the casting’s dimensional accuracy requirements.

Design Considerations for Patterns

Designing a pattern requires foresight and planning to address challenges that may arise during the casting process. Key considerations include:

Draft Angles: Slight tapers applied to vertical surfaces of the pattern to facilitate its removal from the mold without damaging the mold cavity.

Cores and Core Prints: Cores create hollow sections or internal cavities in the cast. Core prints are extensions on the pattern that form recesses in the mold, which support the cores during the casting process.

Shrinkage Allowance: An adjustment made to the pattern dimensions to compensate for the shrinkage of metal as it cools and solidifies. Different metals have different shrinkage rates, requiring precise calculations to ensure the final cast matches the desired dimensions.

- Cast iron: 1/10 to 5/32 inch per foot

- Steel: 1/8 to 1.4 inch per foot

- Aluminum: 1/16 to 5/32 inch per foot

Machine Finish Allowance

The machine finish allowance (or machining allowance) is a critical consideration when a casting is expected to undergo post-casting machining operations, such as grinding, milling, or turning. Essentially, this allowance adds extra material to the final casting, ensuring that enough material remains for the machining process to refine the surface and achieve precise dimensional accuracy. Without this allowance, the cast part could end up too small after machining, potentially rendering it unusable.

One key aspect of machine finish allowance is its role in determining the placement of risers. Risers serve as reservoirs to compensate for metal shrinkage during cooling, but knowing that post-casting machining is required can help the pattern designer position them strategically. The metal around the riser area can be clamped or held securely during machining, ensuring a smooth and efficient post-casting process. This consideration is especially important in high-precision industries, where accuracy is paramount.

Distortion Allowance

The distortion allowance is a crucial step in pattern design, especially when working with metals that are known to distort during the cooling process. As the metal cools and solidifies, internal stresses can cause displacement, resulting in unwanted shape changes. To combat this, the pattern must be designed to account for such distortions, often through a process known as camber.

Camber involves intentionally modifying the pattern to counteract the predictable distortion that will occur when the metal solidifies. This modification allows the final casting to maintain the correct shape and dimensions. For example, if the metal is likely to contract or warp in a specific direction as it cools, the pattern is adjusted with the opposite distortion built in. This thoughtful modification helps the final product retain its intended form, ensuring consistency and precision.

Draft Allowance

In addition to machine finish and distortion allowances, draft allowance plays a vital role, particularly in sand casting patterns. Unlike investment casting, where precision molds are formed from a solid pattern, sand casting patterns must be able to be removed from the mold without damaging the fragile sand cavity. To make this removal process easier, the walls of the pattern are slightly tapered. This tapering, known as "draft," helps reduce the friction between the mold and the pattern, preventing damage and ensuring the integrity of the final casting.

Without a proper draft angle, the pattern could get stuck in the sand mold, causing deformation or cracking. This is why draft allowance is essential for sand casting patterns but unnecessary for investment casting, where the pattern is typically destroyed to retrieve the casting.

Critical Pattern Support Infrastructure

Every successful casting relies on a carefully designed system of channels and reservoirs:

- Pouring Cup: A tapered entry point that controls metal flow and captures slag during pouring.

- Sprue System: The main vertical channel directing metal from the pouring cup into the mold cavity.

- Runners: Horizontal channels distributing metal throughout different areas of the mold.

- Gates: Entry points where metal flows into the casting cavity, sized according to metal cooling rates.

- Risers: Reservoirs of liquid metal that prevent shrinkage defects by continuously feeding the cooling casting. These can be either blind (buried within the mold) or open (visible during pouring).

Pattern Finishing and Color Coding

Professional pattern finishing involves a precise painting system:

- Three-Layer Application: Permanent patterns receive three carefully applied paint coats, ensuring durability and smooth surface finish.

- Color Coding Standards:

- Red surfaces indicate no machining needed

- Yellow marks areas requiring machining

- Black designates core surfaces

- Clear or unpainted areas show parting lines

- Paint Quality: Must be absolutely drip and crack-free to prevent mold defects.

Pattern Storage and Lifecycle Management

- Storage Requirements: Patterns need climate-controlled environments with good airflow to prevent warping and deterioration.

- Economic Considerations: Balancing storage costs against reproduction costs, especially with modern digital design capabilities.

- Digital Integration: CAD systems and digital storage now complement physical pattern storage, offering backup security and easy modification options.

Professional Expertise and Modern Integration

Today's pattern makers blend traditional craftsmanship with modern technology:

- Professional Background: Often coming from cabinetmaking or joinery backgrounds, pattern makers combine woodworking skills with metallurgical knowledge.

- Technical Integration: Modern pattern shops utilize CAD programs and predictive algorithms while maintaining hands-on expertise.

- Production Volume Considerations: Pattern makers must balance material selection, storage solutions, and durability requirements based on production volumes and client needs.

Step-by-Step Guide to Creating a Pattern

Creating a pattern is both an art and a science. Here’s a simplified overview of the steps involved:

- Design Conceptualization: Begin with a detailed drawing or a CAD model of the final casting, considering all necessary allowances and features.

- Material Selection: Choose the appropriate material for the pattern based on the casting requirements and production volume.

- Machining and Assembly: Carve, sculpt, or machine the pattern material to form the exact replica of the casting. For complex shapes, the pattern may be created in parts and then assembled.

- Finishing Touches: Apply surface finishes to the pattern to ensure it imparts a smooth surface to the mold. Add draft angles and finalize core prints.

- Testing and Adjustment: The pattern is often tested to ensure it produces a satisfactory mold. Adjustments may be made to refine the pattern before it’s used for full-scale production.

This phase, teeming with considerations and meticulous planning, underscores the pattern’s role as the cornerstone of the sand casting process. A well-conceived pattern is a harbinger of success, paving the way for a casting that meets the trifecta of fidelity to design, structural integrity, and aesthetic appeal.

FAQ

What is Sand Casting and How Does It Work?

Sand casting is one of the oldest and most versatile metal casting methods used in the manufacturing industry, with origins tracing back to ancient Egypt and China. This time-tested technique has been employed for thousands of years, evolving over centuries to become a cornerstone of modern manufacturing. This blog aims to provide a thorough understanding of sand casting, including its process, materials, advantages, and applications across various industries.

What is Sand Casting?

Sand casting is a flexible and economical casting method used in various industries to produce metal objects and components. The process involves creating a mold from sand, into which molten metal is poured to form the desired shape.

Sand casting is particularly valued for its versatility, as it can produce both small-scale custom items and large-scale industrial parts. The method accommodates a wide range of metals, including steel, aluminum, brass, and iron, making it suitable for diverse applications.

Sand Casting vs. Other Types of Casting

When choosing a casting method, understanding the differences between sand casting, die casting, and investment casting is crucial. Each method has its unique advantages and disadvantages. Sand casting offers several advantages, including being cost-effective for low to medium production volumes, the capability to produce large and complex parts, and accommodating a wide range of material options. However, it does have disadvantages, such as a lower surface finish quality compared to die casting and longer production times. Die casting, on the other hand, boasts advantages such as high production speed, excellent surface finish, and dimensional accuracy, making it ideal for high-volume production of smaller parts. Its drawbacks include higher initial tooling costs and limitations to non-ferrous metals. Investment casting provides superior surface finish and intricate detail, making it suitable for complex geometries and a variety of alloys. Nevertheless, it comes with higher costs and longer lead times, rendering it less ideal for producing large parts.

How Does Sand Casting Work?

Pattern Making

Pattern Making is the first step in the sand casting process. A pattern, which is a replica of the final casting, is created using materials such as wood, metal, or plastic. The pattern includes allowances for shrinkage and machining to ensure the final product meets precise dimensions. This step requires skilled craftsmanship to capture all the details and features required in the casting.

- Materials Used: Patterns are made from wood, metal, or plastic.Metal patterns, typically made from aluminum or steel, offer greater durability and precision compared to wood. They are ideal for high-volume production runs and parts requiring fine details and tight tolerances. .

- Shrinkage Allowances: Patterns are slightly larger to account for metal shrinkage during cooling.

- Core Prints: Patterns may include core prints to position sand cores accurately within the mold.

Mold Making

Mold Making involves creating a mold by packing sand around the pattern. The mold is divided into two halves: the cope (top half) and the drag (bottom half). Once the pattern is removed, the cavity left behind forms the mold for the casting.

- Molding Sand: A mixture of sand, clay, and water (green sand) or chemically bonded sand.

- Cope and Drag: The mold is split into two halves to facilitate pattern removal and metal pouring.

- Compaction Methods: Sand is compacted around the pattern using ramming or vibration techniques to ensure a dense, stable mold.

Core Making

Core Making involves inserting cores into the mold to create internal cavities in the final casting. Cores are made from sand and held together with binders. They are positioned within the mold using core prints on the pattern.

- Core Materials: Typically sand with organic or chemical binders.

- Core Placement: Cores are placed within the mold cavity to form internal passages or complex shapes.

- Chaplets: Metal supports, known as chaplets, may be used to hold cores in place during metal pouring.

Pouring

Pouring is the process of melting the metal and pouring it into the mold cavity. The metal is heated in a furnace until it reaches the required temperature, then transferred to a ladle for controlled pouring into the mold.

- Melting Furnace: Different types of furnaces (e.g., induction, electric arc) are used to melt the metal.

- Pouring Techniques: The metal is poured at a controlled rate to avoid defects like misruns or inclusions.

- Temperature Control: Proper pouring temperature is crucial to ensure complete filling of the mold and optimal metal properties.

Cooling

Cooling allows the molten metal to solidify within the mold. The cooling time depends on the size and complexity of the casting. Controlled cooling is essential to achieve the desired mechanical properties and dimensional accuracy.

- Solidification: The metal solidifies and takes the shape of the mold cavity.

- Cooling Rate: Proper cooling rates prevent defects such as internal stresses or shrinkage cavities.

Removing

Removing involves breaking the mold to retrieve the solidified casting. This step, also known as shakeout, separates the casting from the sand mold.

- Shakeout Methods: Mechanical or manual methods are used to break the mold and remove the casting.

- Handling: Careful handling of the hot casting to avoid damage.

Cleaning

Cleaning is the final step where any excess sand and metal remnants are removed from the casting. This process includes various finishing operations to achieve the desired surface finish and dimensions.

- Sand Removal: Remaining sand is removed using pneumatic tools, brushes, or water jets.

- Finishing Operations: Grinding, blasting, and machining are performed to smooth surfaces and meet dimensional specifications.

- Quality Inspection: Final inspection ensures the casting meets all quality and dimensional requirements.

Materials Used in Sand Casting

The sand casting process relies on various materials to create high-quality molds and castings. Each material plays a crucial role in ensuring the effectiveness and efficiency of the casting process.

Casting Sand

Casting Sand is the primary material used in the sand casting process. High-quality silica sand is commonly used due to its excellent properties, which include high refractoriness, good permeability, and the ability to withstand the high temperatures required for metal casting.

- Silica Sand: The most widely used type of sand in sand casting. It offers high melting points and low thermal expansion, making it ideal for creating stable molds.

- Chromite Sand: Often used for its high heat resistance and thermal conductivity. It’s beneficial for casting metals with high melting points.

- Zircon Sand: Known for its low thermal expansion and high thermal conductivity, zircon sand helps in producing precise castings with minimal defects.

Binders

Binders are materials that hold the sand grains together, providing the mold with the necessary strength and stability. In green sand casting, clay and water are the primary binders used.

- Clay: Bentonite clay is the most common binder used in green sand casting. It provides the necessary cohesiveness to the sand mixture, allowing it to hold its shape during the molding process.

- Water: Acts as an activating agent for the clay, helping it to bind the sand particles together effectively. The moisture content in the green sand mix is crucial for achieving the right mold properties.

Additives

Additives are used to enhance the properties of the sand mold, improving its performance during the casting process. These materials can improve the mold’s strength, permeability, and surface finish.

- Coal Dust: Commonly added to green sand to improve the surface finish of the casting and reduce defects such as gas porosity.

- Organic Compounds: Such as wood flour or cereal binders, are sometimes added to green sand to improve its collapsibility, making it easier to remove the casting from the mold.

- Chemical Binders: In dry sand casting, chemical binders such as sodium silicate or phenolic resins are used to enhance the sand’s bonding properties and improve mold stability.

Types of Sand Used in Casting

There are two basic types of sand used in the sand casting process: green sand and dry sand. Each type has its own composition, characteristics, and applications, making them suitable for different casting needs.

Green Sand vs. Dry Sand

Composition and Characteristics

Green Sand:

- Composition: Green sand is a mixture of silica sand, clay (usually bentonite), and water. Sometimes, organic compounds like coal dust are added to enhance the mold’s strength and surface finish.

- Characteristics: The name “green” refers to the sand’s moisture content. Green sand remains pliable and can be easily shaped and compacted around the pattern. It is not “green” in color but “green” in the sense that it is used in a wet, uncured state. The clay and water act as binders, providing cohesiveness and allowing the mold to hold its shape during metal pouring.

Dry Sand:

- Composition: Dry sand is similar to green sand but without the water content. It is typically baked or cured using chemical binders to increase its strength and stability.

- Characteristics: Dry sand molds are stronger and more rigid than green sand molds. They can withstand higher temperatures and pressures during the casting process, making them suitable for more complex and precise castings. The baking process also reduces the likelihood of defects caused by moisture.

Applications and Benefits

Green Sand:

- Applications: Green sand is widely used in the automotive, aerospace, and general manufacturing industries. It is ideal for producing large, complex shapes such as engine blocks, cylinder heads, and pump housings.

- Benefits:

- Good for casting both ferrous and non-ferrous metals

- Versatility: Easy to mold and reshape,capable of producing a wide range of sizes and shapes, from small intricate parts to large complex components.

- Cost-Effectiveness: Lower production costs compared to other casting methods, making it ideal for both short and long production runs.

- Quality: High-quality castings with excellent mechanical properties, suitable for demanding applications across multiple industries.

Dry Sand:

- Applications: Dry sand is often used for casting intricate and high-precision parts. It is commonly employed in the production of small to medium-sized components that require fine details and tight tolerances, such as aerospace components, medical devices, and high-performance machinery parts.

- Benefits:

- Higher strength and stability compared to green sand.

- Better surface finish and dimensional accuracy.

- Reduced risk of defects related to moisture and gas entrapment

No-Bake Sand Castings:

Sand casting encompasses various types, each tailored for specific applications and requirements. One such type is No-Bake sand casting, which includes Furan and Alphaset. These methods require no baking, relying solely on ramming and binder to hold the mold shape. Within No-Bake sand casting, Shell molding stands out as a notable technique, particularly favored for casting cylinder heads due to its precision and efficiency compared to Dry Sand casting.

Types of Metals Used in Sand Casting

A critical aspect of sand casting is its versatility with different metals. It accommodates all metals except for exotic ones like gallium or mercury. Particularly, sand casting is well-suited for high-cost/high-temperature materials, such as titanium and nickel. Below is a detailed list of metals commonly used in sand casting:

- Aluminum Alloys : Lightweight and corrosion-resistant, ideal for automotive and aerospace applications.

- Cast Iron : Known for its excellent wear resistance, often used in engine blocks and heavy machinery.

- Bronze: Offers high corrosion resistance and is often used in marine applications.

Applications of Green Sand Casting

Automotive Industry

In the automotive sector, green sand casting is essential for manufacturing complex engine components, transmission housings, and various structural parts. Align MFG produces durable and precise castings that meet the stringent requirements of automotive manufacturers.

- Engine Blocks: High-strength engine blocks and cylinder heads are cast using green sand molds to ensure durability and performance under high stress.

- Transmission Housings: The method allows for the creation of complex geometries required for efficient and reliable transmission systems.

Construction Industry

In the construction industry, green sand casting is utilized to produce robust and durable parts for heavy machinery and infrastructure projects. Align MFG’s expertise ensures high-quality castings for these demanding applications.

- Machinery Parts: Large and complex machinery components, such as gear housings and brackets, are cast using green sand molds to ensure strength and longevity.

- Infrastructure Components: Custom castings for bridges, buildings, and other infrastructure elements are made to meet specific design and performance criteria.

Advantages and Disadvantages of Sand Casting

Advantages

- Cost-effective for Small to Medium Production Runs: Sand casting is an economical choice for producing parts in small to medium quantities. The low cost of raw materials and molds makes it a cost-effective solution for various manufacturing needs.

- Capable of Producing Large and Complex Shapes: Sand casting is highly versatile and can be used to produce large and intricate components that might be difficult to create using other methods. This flexibility is particularly beneficial for industries requiring custom and complex shapes. Align MFG are among a handful of manufacturers that can assist with massive scale sand casting projects ranging to over 15 tons, find out more about our large scale sand casting.

- Reusable Sand Molds: The sand used in the casting process can be recycled and reused multiple times, reducing material costs and minimizing waste. This sustainability aspect makes sand casting an environmentally friendly option compared to other casting methods.

- Wide Range of Metal Compatibility: Sand casting can accommodate a variety of metals, including iron, steel, aluminum, brass, and bronze. This versatility allows manufacturers to produce components for different applications using the same casting method.

- Short Lead Times: The simplicity of the sand casting process enables quicker turnaround times for production runs, which is advantageous for meeting tight deadlines and market demands.

Disadvantages

- Lower Dimensional Accuracy Compared to Other Casting Methods: Sand casting generally produces parts with lower dimensional accuracy and a rougher surface finish compared to precision casting methods like investment casting or die casting. Additional machining may be required to achieve the desired specifications.

- Surface Finish May Require Additional Machining: Due to the rough texture of sand molds, the surface finish of sand-cast parts often needs further finishing processes such as grinding, polishing, or machining to meet the required standards.

- Limited Complexity for Fine Details: While sand casting is excellent for large and complex shapes, it may not be suitable for parts that require extremely fine details or tight tolerances. Other casting methods might be more appropriate for such requirements.

- Higher Labor Costs for Complex Parts: The manual aspects of the sand casting process, such as pattern making and mold preparation, can result in higher labor costs, especially for complex parts. Automation and advanced techniques can help mitigate this issue but might increase the initial investment.

Properties Determining the Quality of a Sand Mold

Key Properties

Permeability refers to the ability of the sand mold to allow gases to escape during the casting process. Proper permeability is essential to prevent gas defects, such as porosity, in the final casting.

- Importance: As molten metal is poured into the mold, gases are generated. High permeability ensures that these gases escape through the sand mold rather than becoming trapped within the casting, which could lead to defects and structural weaknesses.

- Measurement: Permeability is typically measured by the rate at which air can pass through a standard sand sample. The sand’s grain size, shape, and distribution all affect its permeability.

Strength

Strength is the ability of the sand mold to retain its shape under pressure and during the metal pouring process. Adequate strength is necessary to maintain the integrity of the mold and prevent it from collapsing or deforming.

- Importance: A strong mold can withstand the mechanical stresses during pattern removal, core setting, and metal pouring without breaking or distorting. This ensures that the casting dimensions remain accurate and consistent.

- Types of Strength:

- Green Strength: The strength of the mold when it is still moist.

- Dry Strength: The strength of the mold after it has dried and hardened.

- Hot Strength: The mold’s strength at elevated temperatures, crucial during the actual pouring of molten metal.

Refractoriness

Refractoriness is the ability of the sand mold to withstand high temperatures without breaking down or melting. This property is critical when casting metals with high melting points.

- Importance: High refractoriness ensures that the sand mold does not degrade or fuse with the molten metal during the casting process, which could result in defects and surface imperfections in the final product.

- Materials Contributing to Refractoriness: Silica sand is commonly used due to its high melting point. Other materials, like zircon and chromite sands, are also used to enhance refractoriness for specific applications.

Precision and Tolerances in Sand Casting

Sand casting can achieve a decent level of precision and tolerances, but it is generally less accurate than other methods like investment casting or die casting. Precision depends on factors such as mold quality and the casting process control.

- Mold Quality: The precision of the mold directly influences the accuracy of the casting. High-quality molds with fine sand grains can produce smoother surfaces and more accurate dimensions.

- Pattern Design: Accurate pattern design with appropriate allowances for shrinkage and machining ensures that the final casting meets the required dimensions. Patterns must also include draft angles to facilitate easy removal from the mold without damaging the sand walls.

- Core Placement: Proper placement and securing of cores within the mold are crucial for achieving the desired internal geometries and maintaining dimensional accuracy.

- Pouring Techniques: Controlled pouring of molten metal at the correct temperature and speed helps prevent defects such as misruns, cold shuts, and inclusions, which can affect the precision of the casting.

- Cooling Rate: Uniform and controlled cooling prevents warping and ensures the casting retains its intended shape and dimensions. Variations in cooling rates can lead to internal stresses and dimensional inaccuracies.

Industry Standards and Tolerances

Industry Standards and Tolerances define acceptable levels of dimensional variations in cast components. These standards ensure that castings meet the functional and performance requirements of their intended applications.

- Dimensional Tolerances: Sand casting generally achieves dimensional tolerances of ±0.020 inches per inch. However, this can vary based on the complexity of the part and the skill of the foundry.

- Surface Finish: The surface finish of sand-cast parts is typically rougher than that of investment or die-cast parts. Secondary machining processes are often required to achieve smoother surfaces and tighter tolerances.

- Geometric Tolerances: Geometric tolerances, including flatness, roundness, and concentricity, are crucial for ensuring the parts fit and function correctly. These tolerances are specified according to industry standards to maintain consistency and quality from Align MFG.

Design Considerations

Shrinkage Allowances:

- Importance: During cooling, molten metal shrinks as it solidifies. Patterns must be designed larger than the final casting to account for this shrinkage, ensuring that the final dimensions are accurate.

- Calculation: The amount of shrinkage allowance depends on the type of metal being cast. Different metals have different shrinkage rates, and these must be factored into the pattern design.

Draft Angles:

- Purpose: Draft angles are slight tapers added to the vertical surfaces of the pattern to facilitate its removal from the mold without damaging the mold walls.

- Specification: The angle of the draft depends on the complexity and depth of the pattern. Common draft angles range from 1° to 3°.

Core Prints:

- Function: Core prints are features added to the pattern to create recesses in the mold where sand cores will be placed. These ensure proper positioning and support of the cores during the casting process.

- Design: Core prints must be accurately designed to match the size and shape of the cores, providing stability and preventing movement during metal pouring.

Machining Allowances:

- Necessity: Additional material is added to the pattern to allow for machining and finishing processes after casting. This ensures that the final part meets the precise specifications and surface finish requirements.

- Allowance Size: The amount of machining allowance depends on the casting’s size, complexity, and the required finish. Typically, allowances range from 1.5 mm to 3 mm for most applications.

Functions of Cores and Chaplets

Cores and chaplets play essential roles in the sand casting process, enabling the creation of complex internal geometries and providing support within the mold. Understanding their functions helps ensure the production of high-quality castings.

Achieving Temper in Sand Casting

Achieving temper in sand casting involves controlling the moisture content and compactability of the sand to ensure optimal mold conditions. Proper tempering of the sand is crucial for creating high-quality molds that produce accurate and defect-free castings.

Tempering Process

The tempering process in sand casting is essential for preparing the sand mixture to achieve the right consistency and properties for molding. This process involves adding the correct amount of water and other additives to the sand, followed by thorough mixing to distribute moisture evenly.

Techniques and Best Practices:

- Moisture Control: Maintaining the appropriate moisture content is critical for achieving the desired sand temper. Too much moisture can lead to a weak mold, while too little can result in poor sand cohesion and mold instability/

- Measurement Tools: Use moisture meters to regularly check the moisture content of the sand. Aim for a consistent moisture level, typically between 2-4%, depending on the specific requirements of the casting process.

- Water Addition: Gradually add water to the sand mixture while continuously mixing to ensure even distribution. This helps achieve the desired moisture content without oversaturating the sand.

- Compactability: The compactability of the sand affects the mold’s strength and surface finish. Proper compaction ensures that the sand particles are tightly packed, providing a stable and robust mold.

- Compaction Methods: Utilize ramming, squeezing, or jolting techniques to compact the sand around the pattern. These methods help achieve uniform density and improve the mold’s overall integrity.

- Additives: Incorporate additives such as bentonite clay and coal dust to enhance the sand’s compactability and overall performance. Bentonite increases cohesion, while coal dust improves surface finish by reducing metal penetration and burn-on defect.

- Mixing Equipment: Use appropriate mixing equipment to ensure the sand mixture is homogeneous. Mechanical mixers or mullers are commonly used to achieve consistent sand properties throughout the batch.

- Mixing Duration: Ensure adequate mixing time to distribute moisture and additives evenly. Overmixing can degrade the sand particles, while undermixing can result in uneven tempering.

Advanced Sand Casting Technologies: Disamatic Innovations

Advanced technologies in sand casting have revolutionized the industry, enhancing efficiency and precision in manufacturing. One such technology is the Disamatic molding system, well-known among foundry professionals. Disamatic offers cutting-edge solutions like the DISA FLEX and DISA MATCH, which provide high-quality molding capabilities. The DISA FLEX combines the versatility of a horizontal flask molding machine with the speed and precision of modern automation, making it ideal for various casting applications. Similarly, the DISA MATCH delivers superior accuracy and repeatability, ensuring consistent quality in every cast. These innovations streamline the sand casting process, reducing waste and improving overall productivity. For more details, you can explore DISA FLEX and DISA MATCH.

Examples of Sand Casting Products

The versatility and broad applicability of sand casting are exemplified through various products across multiple industries. Here are some standout examples:

– Engine Blocks: Integral to automotive and industrial engines, these components exemplify the method’s strength and durability.

– Pulleys and Gears: Critical machinery parts that showcase the precision achievable through sand casting.

– Medium-Speed Marine Diesel Flywheels: These can weigh several tons, demonstrating the method’s ability to handle significant mass.

– Marine Applications: Through-hull nickel-aluminum bronze fittings in boat and ship hulls, illustrating corrosion resistance and robustness.

– Barbecue Grills and Burner Components: Common household and commercial items that benefit from sand casting’s adaptability.

– ICE Engine Blocks and Vehicle Brake Discs: Essential automotive parts ensuring safety and performance.

– Door Furniture: Stylish and functional elements in residential and commercial settings.

– Heavy Machinery and Oil Field Tools: Durable tools designed to withstand harsh environments.

– Jewelry: Crafted from various precious and common metals, showcasing intricate detailing.

These examples highlight how sand casting can deliver both functional and artistic results through its wide-ranging applications.

Conclusion

Sand casting remains a vital process in the manufacturing industry due to its versatility and cost-effectiveness. By understanding its stages, materials, advantages, and applications, businesses can make informed decisions about utilizing this method for their production needs.

For more information on sand casting or to receive a personalized quote, contact Align Manufacturing today. Our team is ready to assist you in selecting the best casting method for your project needs, ensuring quality and efficiency.