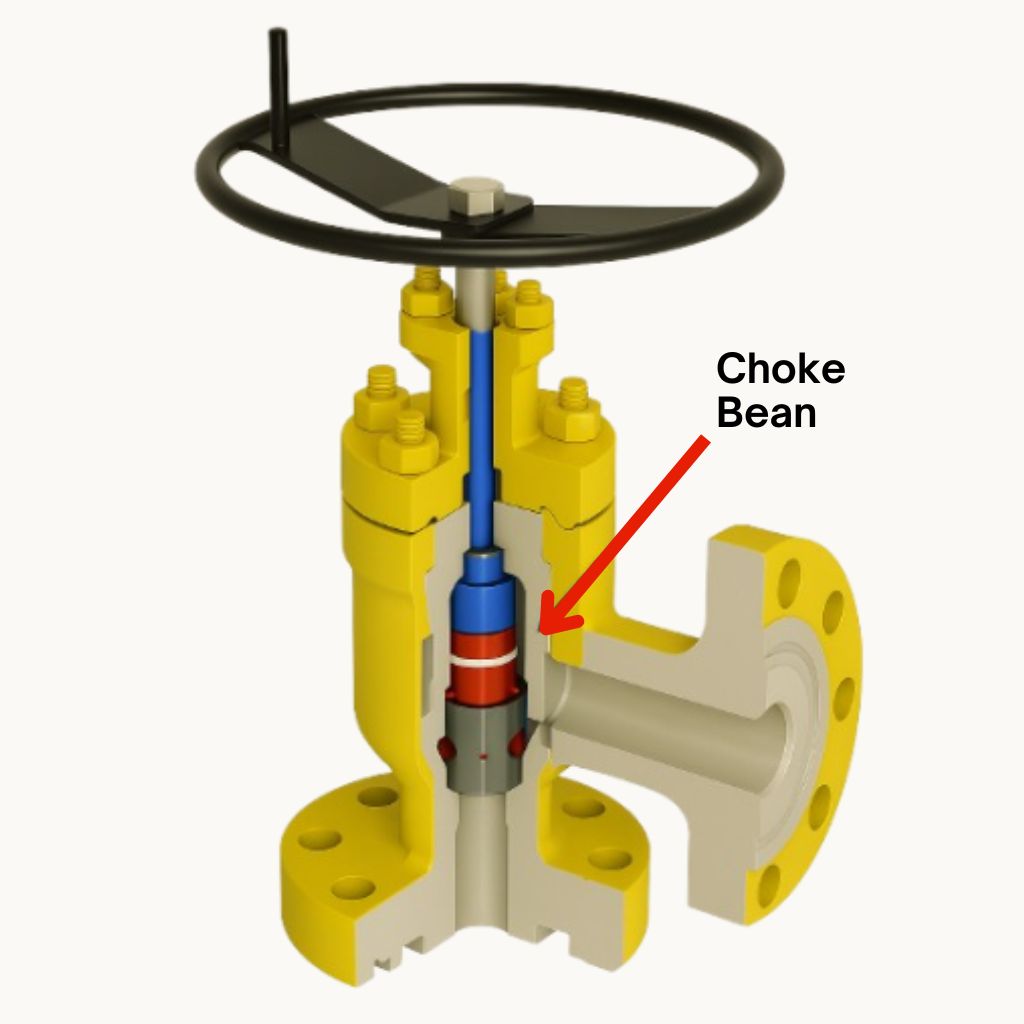

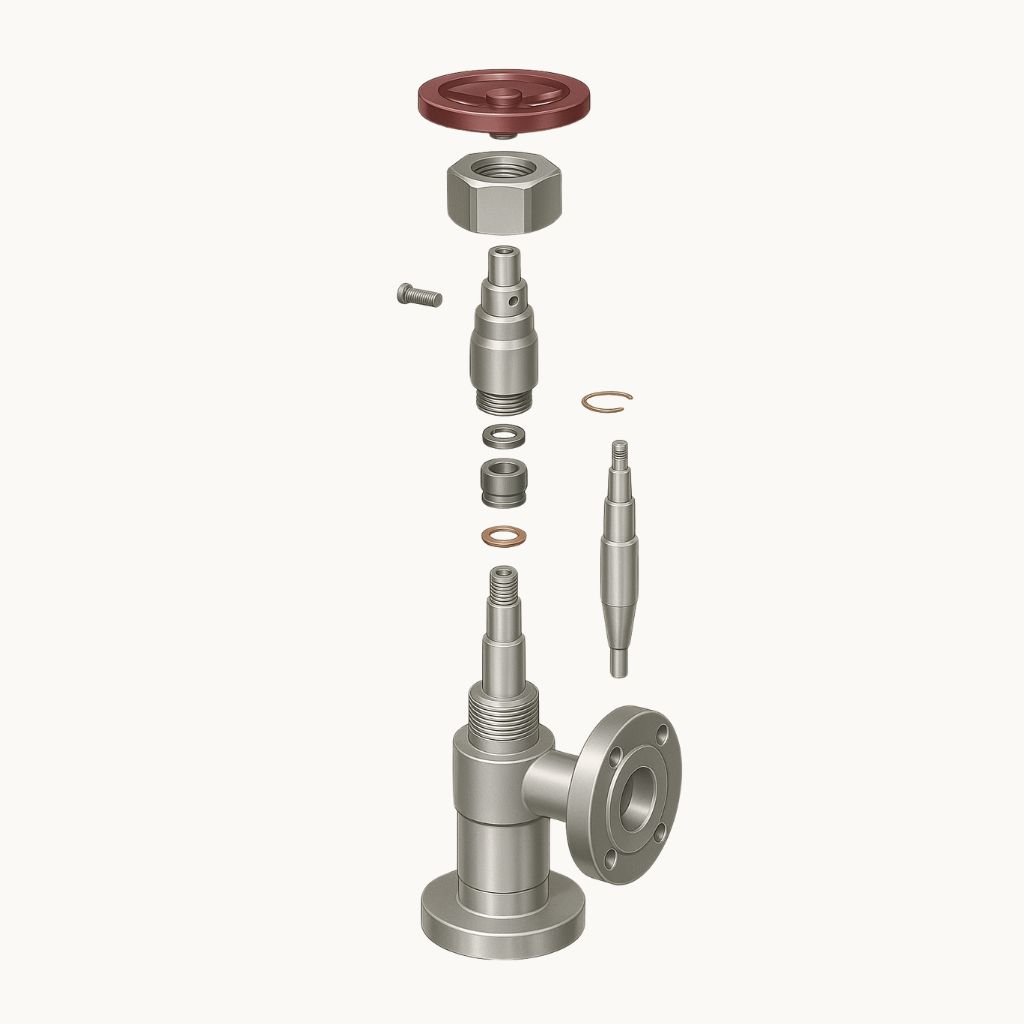

Choke Bodies and Choke Beans for Oil and Gas

High-Performance Flow Control Components for Critical Pressure Management

Overview

Choke Bodies and Choke Beans Component Manufacturing

Chokes and choke beans are fundamental to controlling well pressure and regulating flow during drilling, completion, and production operations. Align Manufacturing supplies precision-machined choke bodies, housings, and choke beans to energy OEMs and equipment builders worldwide, ensuring durable, erosion-resistant flow control even under extreme operating conditions.

Our choke components are manufactured in trusted offshore facilities with rigorous quality oversight, providing Western-level manufacturing standards with supply chain transparency built in.

Choke Components in Manifold and Flowline Systems

Choke assemblies are critical elements within larger manifold systems, controlling flowback pressure during hydraulic fracturing, well testing, and production operations. Our choke bodies and beans integrate into manifold modules alongside plug valves, gate valves, and pressure fittings — providing a seamless fit and reliable service life.

By ensuring precision-machined tolerances and high-quality material sourcing, Align helps manifold builders and flowline OEMs extend uptime and reduce maintenance cycles.

Align MFG Choke Components

Why OEMs and Energy Equipment Providers Choose Align

-

Predictable quality from offshore production centers

-

Flexible batch sizes — prototyping to high-volume production

-

Material selection support for erosion and sour service

-

Dimensional consistency and full documentation

Resources

In addition to our manufacturing capabilities, Align MFG plays a crucial role in optimizing supply chains. Our expertise in consolidating shipments, especially in regions like Vietnam, India, and Thailand , significantly reduces logistics costs and enhances efficiency, offering a reliable alternative to traditional sourcing from China. You can read more details about this below.

Partner with Align MFG for Premium Oil & Gas Choke Parts

Our dedication to quality is matched by our commitment to effective communication. Keeping clients informed and involved is a priority, ensuring a seamless experience from order to delivery.

Discover the difference with Align MFG’s Oil and Gas parts. Contact us to explore how our expertise in metal manufacturing can reduce operational costs. Trust Align MFG for components that drive efficiency and reliability.