API 6A Ring Gaskets for Oil and Gas

Precision-Machined Metal Seals for Extreme Pressure Applications

Overview

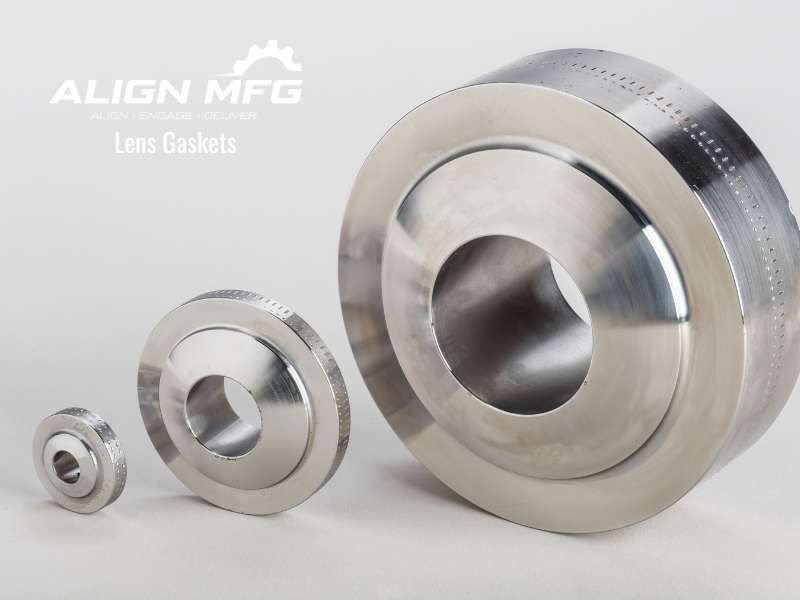

API 6A Ring Gaskets Component Manufacturing

API 6A ring gaskets form the backbone of high-pressure sealing in upstream oil and gas operations. Used across wellhead assemblies, blowout preventers (BOPs), and manifold systems, these metal-to-metal gaskets ensure zero-leak performance under extreme temperature and pressure cycles.

Align Manufacturing produces API 6A-compliant ring gaskets in R, RX, and BX profiles, built from NACE-compliant materials and machined with exacting dimensional control. Our global production model, spanning facilities in India, Vietnam, and Thailand, delivers parts that meet Western quality expectations without the unpredictability often associated with offshore sourcing.

Ring Gaskets in Manifolds and Flanged Connections

In addition to standalone wellhead and BOP applications, API 6A ring gaskets play a critical role in the reliable performance of manifolds and flanged flowline connections.

Frac manifolds, choke manifolds, and flowback skids often rely on properly specified BX or RX gaskets to maintain pressure integrity across high-load cycles. Misalignment or improper material selection can lead to leaks, downtime, and safety risks — which is why Align offers expert support in material selection and profile specification to match your system needs.

Align MFG API 6A Ring Gaskets

Why Oilfield OEMs and Equipment Builders Choose Align

-

Precision manufacturing for extreme sealing performance

-

Global production with Western QA oversight

-

Flexible batch sizes — from rapid prototyping to high-volume orders

-

Engineering collaboration — ensure the right material, hardness, and profile for your pressure class

Resources

In addition to our manufacturing capabilities, Align MFG plays a crucial role in optimizing supply chains. Our expertise in consolidating shipments, especially in regions like Vietnam, India, and Thailand , significantly reduces logistics costs and enhances efficiency, offering a reliable alternative to traditional sourcing from China. You can read more details about this below.

Partner with Align MFG for Premium Oil & Gas API 6A Ring Gaskets

Our dedication to quality is matched by our commitment to effective communication. Keeping clients informed and involved is a priority, ensuring a seamless experience from order to delivery.

Discover the difference with Align MFG’s Oil and Gas parts. Contact us to explore how our expertise in metal manufacturing can reduce operational costs. Trust Align MFG for components that drive efficiency and reliability.