Hammer Union Components for Oil and Gas

Reliable Flowline Connections, Built to U.S. Standards, Delivered Without Surprises

Overview

Hammer Union Component Manufacturing

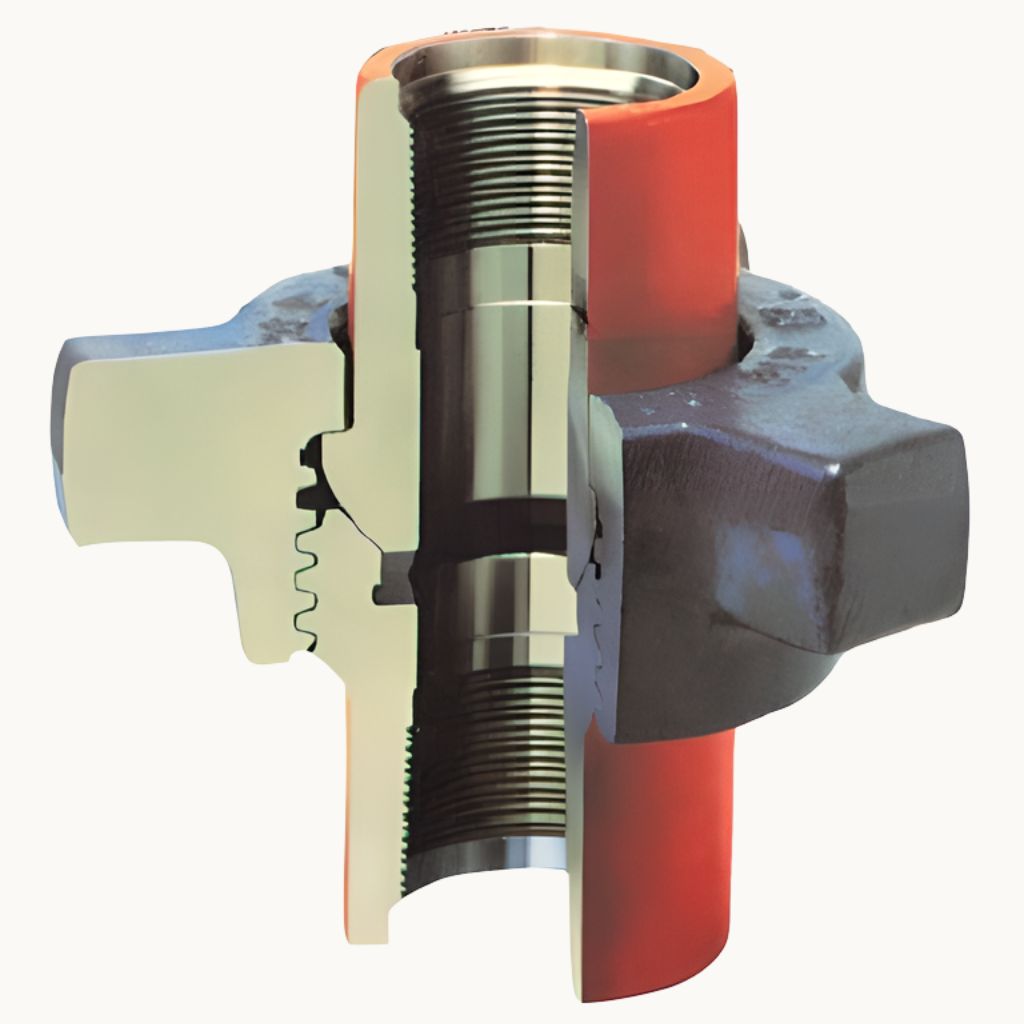

Hammer unions are vital for safe, fast connection and disconnection of pressurized piping systems across upstream oil and gas operations. Whether supporting flowback, hydraulic fracturing, mud circulation, or well testing, every connection point must hold up to extreme pressure, shock loads, and corrosive fluids.

Align Manufacturing produces high-tolerance hammer union components, including male subs, female subs, nuts, and seals, engineered to meet the rigorous performance demands of oilfield applications. Manufactured at trusted facilities in India, Vietnam, and Thailand, our parts align with API and NACE standards, and are quality-checked for dimensional integrity and material compliance.

Integration into Manifolds and Flowline Systems

Hammer unions are critical components in the modular assembly of flow iron, frac manifolds, and test loops. Correct material selection and machining accuracy are essential to maintaining seal integrity under thermal cycling and pressure shock.

Align supports OEMs and system integrators with expert machining of union parts that slot seamlessly into manifold builds and flanged flowline systems, reducing fit-up issues and field failures.

Align MFG Hammer Unions

Why Flow Control Builders Trust Align

-

Reduced offshore sourcing risk with Western-managed QA and communication

-

Flexibility for prototyping or volume runs

-

Traceable materials and full inspection reporting

-

Engineering collaboration for specialized or legacy hammer union designs

Resources

In addition to our manufacturing capabilities, Align MFG plays a crucial role in optimizing supply chains. Our expertise in consolidating shipments, especially in regions like Vietnam, India, and Thailand , significantly reduces logistics costs and enhances efficiency, offering a reliable alternative to traditional sourcing from China. You can read more details about this below.

Partner with Align MFG for Premium Oil & Gas Hammer Unions

Our dedication to quality is matched by our commitment to effective communication. Keeping clients informed and involved is a priority, ensuring a seamless experience from order to delivery.

Discover the difference with Align MFG’s Oil and Gas parts. Contact us to explore how our expertise in metal manufacturing can reduce operational costs. Trust Align MFG for components that drive efficiency and reliability.