Valve Bonnets for Oil and Gas

Precision-Manufactured Bonnets for High-Pressure Valve Systems

Overview

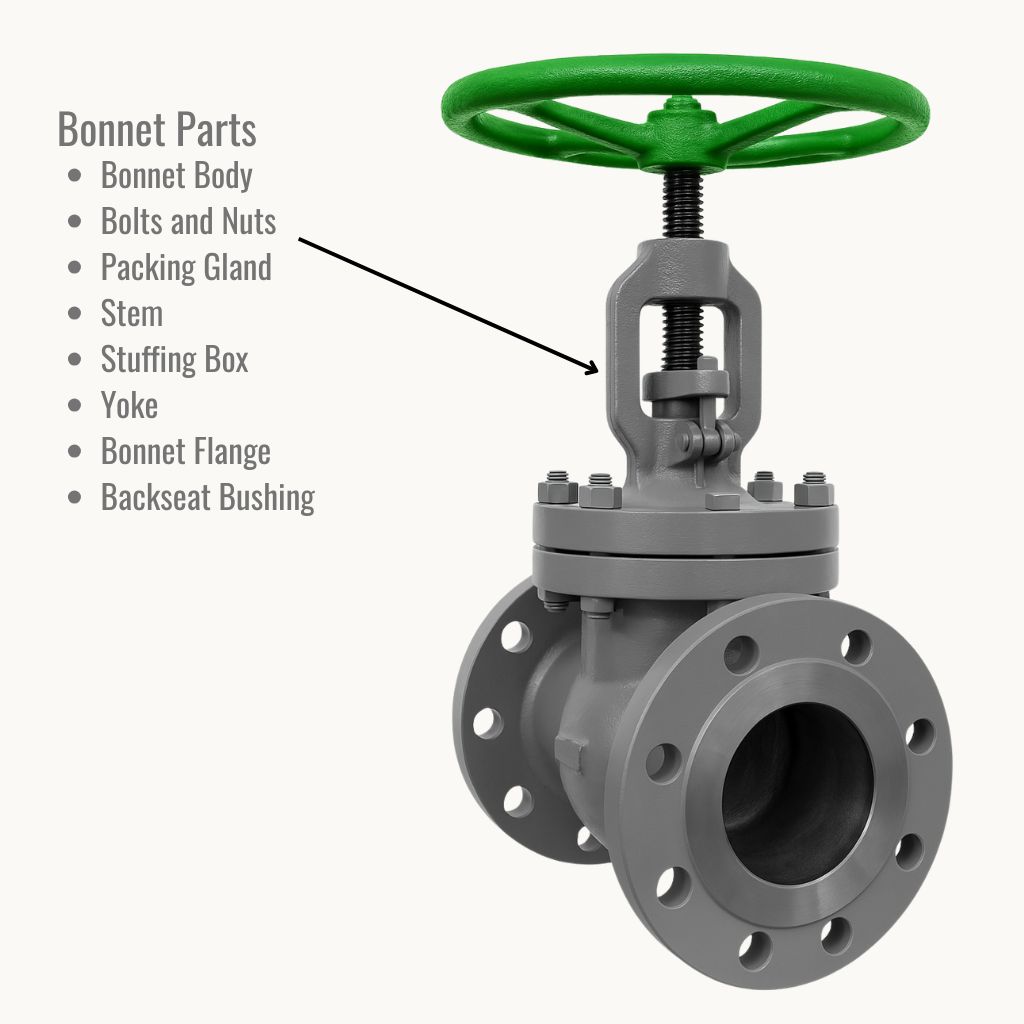

Valve Bonnet Parts Manufacturing

Bonnets are essential structural components that seal valve internals against high-pressure flow, guide actuation elements, and ensure long-term operational integrity in demanding oilfield environments.

At Align Manufacturing, we machine and fabricate bonnets for API 6A-compliant valves, built to the dimensional, metallurgical, and inspection standards required by the world’s leading energy OEMs. Manufactured across India, Vietnam, and Thailand under strict QA oversight, our bonnets deliver reliable sealing performance and precise alignment for gate, plug, and check valves.

Bonnets in Manifold and Pressure Control Systems

In addition to standalone valve assemblies, Align-manufactured bonnets are essential parts of larger systems like frac manifolds, flowback trees, and kill systems. They ensure pressure containment and enable rapid, reliable actuation even under high cyclic loading conditions, critical for maintaining well control and operational efficiency.

Align MFG Valve Bonnets

Why Oilfield Equipment Builders Choose Align

-

Global manufacturing with local QA presence

-

Repeatable quality across production batches

-

Flexible order sizes — from prototyping to serial production

-

Engineering expertise in critical dimensions, sealing surfaces, and API compliance

Resources

In addition to our manufacturing capabilities, Align MFG plays a crucial role in optimizing supply chains. Our expertise in consolidating shipments, especially in regions like Vietnam, India, and Thailand , significantly reduces logistics costs and enhances efficiency, offering a reliable alternative to traditional sourcing from China. You can read more details about this below.

Partner with Align MFG for Premium Oil & Gas Valve Bonnets

Our dedication to quality is matched by our commitment to effective communication. Keeping clients informed and involved is a priority, ensuring a seamless experience from order to delivery.

Discover the difference with Align MFG’s Oil and Gas parts. Contact us to explore how our expertise in metal manufacturing can reduce operational costs. Trust Align MFG for components that drive efficiency and reliability.