Valve Stems for Oil and Gas

Precision-Machined Stems for Critical Valve Actuation

Overview

Valve Stem Manufacturing

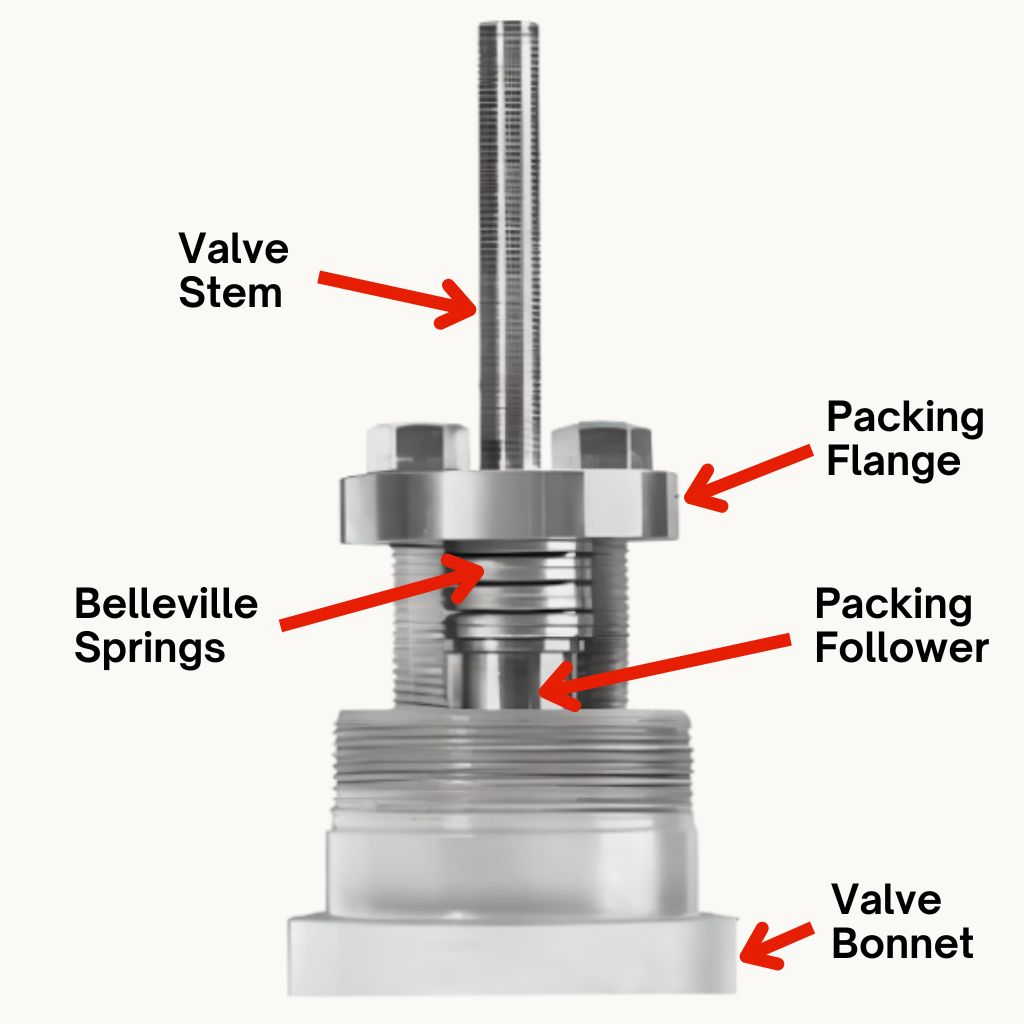

Valve stems are the unsung heroes of pressure control equipment, responsible for transmitting motion, maintaining seals, and ensuring reliable valve operation in some of the harshest oilfield environments.

Align Manufacturing delivers high-precision valve stems machined to meet the extreme demands of oil and gas applications, from wellhead isolation to high-pressure hydraulic fracturing systems. Produced in ISO-certified facilities across India, Vietnam, and Thailand, our stems are built to exacting tolerances with full material and dimensional traceability, reducing supply chain risk while meeting API/NACE performance standards.

Valve Stems in Broader Oilfield Systems

Valve stems are critical components in manifolds, frac skids, surface wellhead assemblies, and flow control trees. Whether part of a frac manifold’s plug valves or a production tree’s gate valves, a properly specified stem ensures consistent actuation and leak-free performance.

Misaligned threads, improper hardening, or material mismatch can result in costly valve failure. which is why Align offers engineering support to match material grades and manufacturing processes to your operational environment.

Align MFG Valve Stems

Why Leading OEMs and Operators Trust Align

-

Predictable offshore manufacturing — controlled to U.S. tolerances

-

Material expertise for HPHT, sour gas, and cyclic service

-

Responsive quoting and DFM collaboration

-

High-precision, serialized production for better lifecycle tracking

Resources

In addition to our manufacturing capabilities, Align MFG plays a crucial role in optimizing supply chains. Our expertise in consolidating shipments, especially in regions like Vietnam, India, and Thailand , significantly reduces logistics costs and enhances efficiency, offering a reliable alternative to traditional sourcing from China. You can read more details about this below.

Partner with Align MFG for Premium Oil & Gas Valve Stems

Our dedication to quality is matched by our commitment to effective communication. Keeping clients informed and involved is a priority, ensuring a seamless experience from order to delivery.

Discover the difference with Align MFG’s Oil and Gas parts. Contact us to explore how our expertise in metal manufacturing can reduce operational costs. Trust Align MFG for components that drive efficiency and reliability.