High-Pressure Die Casting at Align MFG

At Align MFG, we specialise in delivering precision-engineered die cast components for a wide range of industries across the United States and globally. While our facilities operate in key manufacturing hubs such as Thailand, Vietnam, India, and the United States, more specialised expertise in Thailand high pressure die casting is detailed on our dedicated resource page. Here, our focus remains on crafting high-quality aluminium and zinc parts that meet international standards for strength, performance, and reliability.

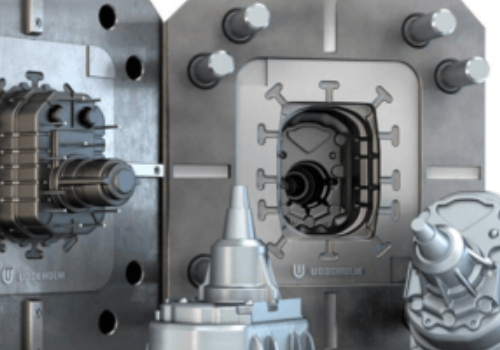

Our Process

Align MFG is a leading supplier of high-pressure die-casting services to the oil and gas industry.

Die Cast Vent Release valve

- Oil and Gas

- High Pressure Die Cast

- 380 ALUMINUM

- Clear Anodizing

- 20,000 per year

- Vietnam

We also provide various product offerings that meet the rigorous demands of diverse industries.

Discover our other industries

We use materials such as aluminium and zinc alloys to create parts according to your drawing specifications. We are committed to providing our customers with the highest quality products and services. Our team of experienced engineers and technicians is dedicated to meeting your needs.

Contact us today to learn more about our high-pressure die casting services.

Why Choose Align MFG

for Die Casting?

Precision Manufacturing

Experience precision manufacturing, where our skilled technicians work together to produce high-quality castings each time.

Materials Expertise

Specializing in both aluminium and zinc, we provide versatile solutions tailored to your specific requirements.

Global Reach, Local Expertise

With high-pressure die casting factories in the United States, Thailand, Vietnam, and India, we combine global reach with local expertise, ensuring seamless service and support.