Align MFG directly crafts each project with precision and expertise, utilizing advanced machining technologies to fulfill your specific project requirements.

Our services meet the stringent standards of U.S. and international industries, ensuring accuracy and consistency for demanding industrial applications.

Our Precision Machining Expertise

- All Types of Machines for Precise Results: At Align MFG, we utilize a wide array of advanced machinery, including CNC, Lathe, 3-Axis, 5-Axis, VMC, and HMC, to deliver products that precisely meet your specifications.

- Skilled Professionals: Our team of experts guarantees that every component adheres to American precision standards, ensuring that the quality of each product is never compromised.

This diverse range of equipment, coupled with our skilled craftsmanship, ensures effective techniques in every project.

Metals We Master: Steel and Aluminium

- Steel Machining: Precision in every cut, strength in every component.

- Aluminum Machining: Lightweight yet sturdy, machined to perfection.

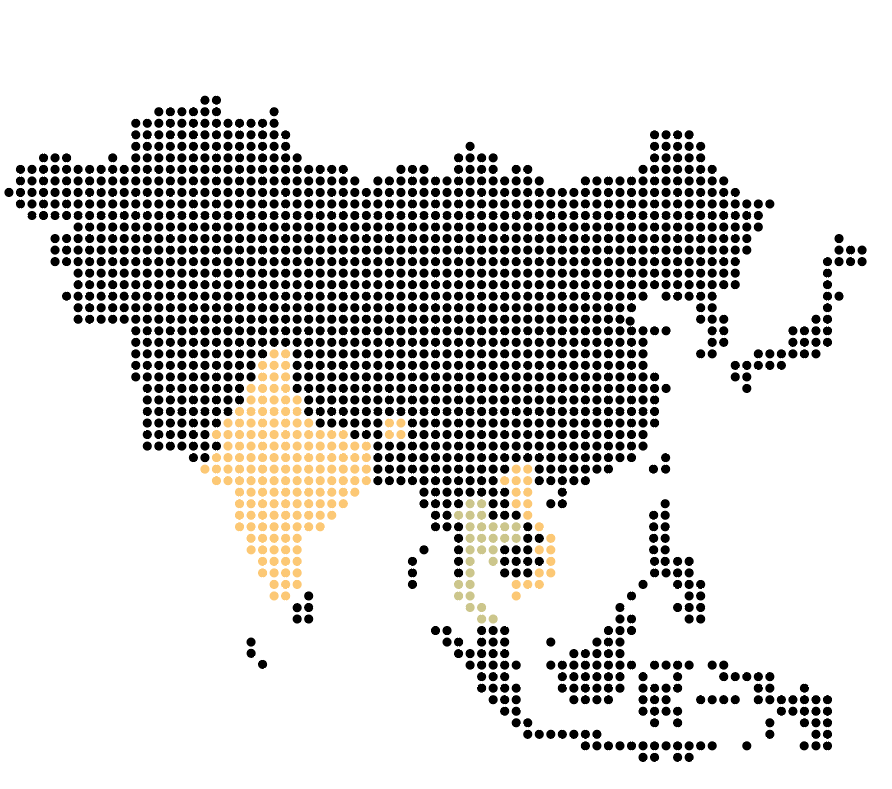

Western-Owned,Local Expertise

- Thailand: Specializing in intricate designs and complex projects.

- Vietnam: Your destination for large-scale, efficient production.

- India: Versatile and adaptable precision machining for various applications.

- United States: Supervises all international operations, ensuring compliance with American quality standards.

Why Choose Align MFG?

- Crystal Clear Communication: We guarantee a smooth, transparent process, ensuring your project's requirements are met precisely.

- Commitment to Timelines: Your deadlines are our priority. Expect on-time delivery, every time.

- Staying Within Your Budget: Align MFG delivers premium quality while ensuring we adhere strictly to the agreed budget.

FAQ

Get Started with Your Project

Have a project in mind? Submit your RFQ now. We're here to efficiently turn your specifications into high-quality results.