Anodizing vs Powder Coating: Which Finish Lasts Longer?

Anodizing and powder coating are two of the most widely used metal finishing processes for improving durability, corrosion resistance, and appearance. Anodizing is an electrochemical process that transforms the metal surface itself, while powder coating applies a protective polymer layer on top of the metal. According to manufacturing and architectural finishing data, surface treatments can extend the service life of aluminum components by 10–20+ years, depending on environment and usage.

This article compares anodizing and powder coating with a clear focus on which finish lasts longer. It covers how each process works, their durability mechanisms, performance in real-world environments, and the factors that directly influence lifespan.

What Is Anodizing?

Anodizing is an electrochemical finishing process that thickens and strengthens the natural oxide layer on aluminum, making it an integral part of the metal rather than a surface coating.

Unlike paints or coatings that sit on top of the material, anodizing converts the aluminum surface into a dense, corrosion-resistant oxide through controlled oxidation in an acid electrolyte bath.

How the Anodizing Process Works

The anodizing process involves:

- Submerging aluminum in an electrolytic solution (commonly sulfuric acid)

- Passing an electric current through the metal

- Growing a controlled aluminum oxide layer inward and outward from the surface

Because the oxide layer is part of the metal substrate, it cannot peel, flake, or blister, which is a critical factor in long-term durability.

Types of Anodizing and Their Durability

| Anodizing Type | Typical Use | Durability Level |

| Type I (Chromic) | Aerospace | Moderate |

| Type II (Sulfuric) | Architectural, consumer products | High |

| Type III (Hard Anodizing) | Industrial, marine, military | Very High |

Hard anodizing (Type III) can achieve surface hardness comparable to hardened steel, significantly improving wear resistance in harsh environments.

What Is Powder Coating?

Powder coating is a dry finishing process where finely ground polymer powder is electrostatically applied to metal surfaces and then cured under heat to form a smooth, protective layer.

Unlike anodizing, powder coating creates a separate external layer that bonds mechanically and chemically to the metal during curing.

How Powder Coating Works

The powder coating process includes:

- Surface cleaning and pretreatment

- Electrostatic spraying of powder particles

- Oven curing at temperatures typically between 160–200°C

The result is a thick, uniform finish that provides good corrosion resistance and excellent aesthetic flexibility.

Common Powder Coating Materials

Powder coatings vary widely in performance depending on formulation:

- Polyester powders – Good UV resistance for outdoor use

- Epoxy powders – Excellent adhesion but limited UV resistance

- Hybrid systems – Balance between durability and cost

Key Differences Between Anodizing and Powder Coating

The fundamental difference between anodizing and powder coating lies in how each finish protects the metal.

- Anodizing becomes part of the aluminum surface

- Powder coating acts as a protective shell over the surface

Bonding Mechanism Comparison

| Factor | Anodizing | Powder Coating |

| Bonding | Integrated with metal | Surface adhesion |

| Peeling Risk | None | Possible if damaged |

| Thickness | Thin but dense | Thick polymer layer |

| Repairability | Difficult | Easier to recoat |

Because anodizing is not a coating in the traditional sense, surface damage does not propagate peeling or widespread failure.

Durability and Wear Resistance

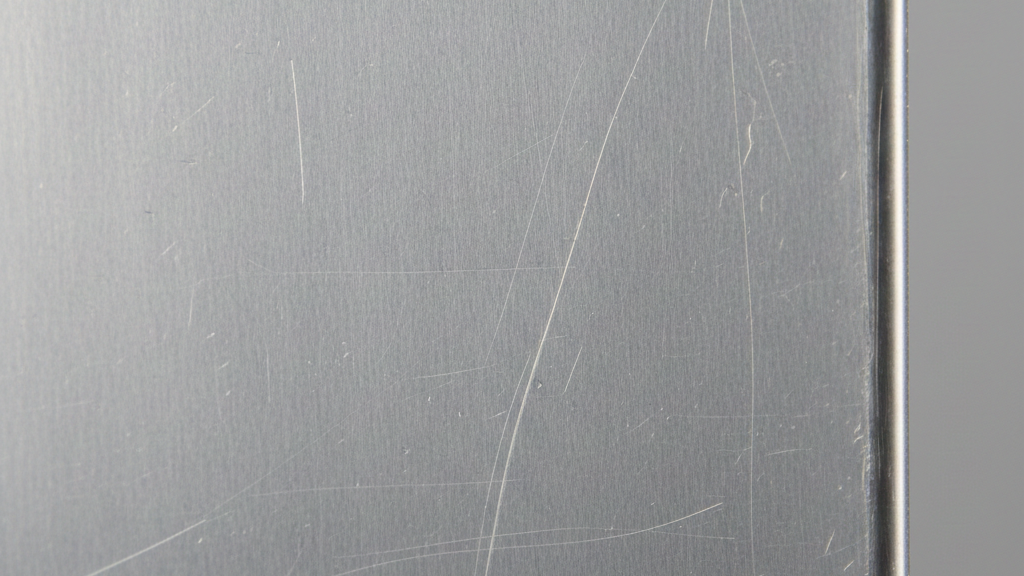

Durability refers to how well a finish withstands abrasion, impact, and daily wear over time.

Anodized aluminum offers superior abrasion resistance because the oxide layer is extremely hard and tightly bonded. Manufacturing studies consistently show anodized surfaces outperform powder-coated ones in scratch and wear testing.

Powder coating, while tough, is still a polymer-based finish. Sharp impacts or repeated friction can eventually chip or wear through the coating, exposing bare metal underneath.

Corrosion Resistance Over Time

Corrosion resistance plays a major role in determining which finish lasts longer, especially in outdoor, coastal, or humid environments.

Anodizing excels in corrosion resistance because:

- The oxide layer seals the aluminum surface

- Scratches do not spread corrosion beneath the finish

- Additional sealing treatments further enhance protection

Powder coating also provides good corrosion resistance, but its performance depends heavily on maintaining an intact coating layer. Once moisture penetrates through chips or cracks, corrosion can spread under the coating and shorten its lifespan.

UV and Environmental Resistance

Exposure to sunlight, humidity, and temperature extremes significantly affects the longevity of metal finishes.

- Anodizing: Naturally UV stable, meaning colors will not fade over time. Hard anodized layers can withstand high temperatures and harsh outdoor conditions without degradation.

- Powder Coating: UV stability depends on the powder formulation. Polyester-based powders are more UV resistant, whereas epoxy-based powders may fade or chalk in prolonged sun exposure. Extreme heat can also soften the coating if outside the recommended curing range.

Impact of Wear and Maintenance

Real-world performance is influenced by everyday wear and maintenance practices.

- Anodized surfaces are highly resistant to scratches and abrasion. Minor surface damage does not compromise corrosion protection. Repairing deep damage typically requires professional re-anodizing.

- Powder-coated surfaces can chip or scratch under heavy use. However, minor damage can be repaired with touch-up powder or spray coatings, although achieving the original smooth finish may be difficult.

Maintenance Tips for Longevity:

- Regular cleaning with non-abrasive detergents

- Prompt touch-up of any visible scratches or chips (for powder-coated surfaces)

- Avoid harsh chemical cleaners that can erode anodized or coated surfaces

Lifespan Comparison

Based on industrial studies and field observations:

| Finish | Estimated Lifespan | Key Factors |

| Anodizing | 15–20+ years | Hardness, oxide integration, environment, sealing quality |

| Powder Coating | 10–15 years | Coating thickness, UV-stable powder, surface prep, environmental exposure |

Conclusion

Both anodizing and powder coating enhance the durability and appearance of aluminum, but anodizing generally lasts longer due to its integration with the metal substrate, superior abrasion resistance, and natural UV stability. Powder coating provides excellent aesthetics and good corrosion resistance, but its lifespan is contingent on the integrity of the applied layer.

At Align MFG, we specialize in precision anodizing and powder coating services designed to meet the highest standards of durability and quality. By leveraging our expertise, clients can ensure that their architectural, industrial, or decorative projects achieve maximum longevity and maintain a premium finish.