What is Quenching? The Science of Rapid Steel Cooling

Quenching is a fundamental heat treatment process in metallurgy that involves the rapid cooling of steel after it has been heated to a high temperature. This sudden temperature change alters the steel’s internal structure, significantly improving properties such as hardness, strength, and wear resistance. According to ASM International, quenching is one of the most widely used thermal processes in modern manufacturing, especially for components that must withstand high mechanical stress.

In this article, we explore what quenching is, how it works at the atomic level, the science behind rapid steel cooling, and how manufacturers control the process to tailor material properties.

What Is Quenching?

Quenching is the process of rapidly cooling heated steel by immersing it in a liquid or gas medium such as water, oil, polymer solutions, or air. The primary objective of quenching is to lock in a specific microstructure that enhances hardness and strength.

In practical terms, quenching prevents steel from cooling slowly, which would otherwise result in softer structures like pearlite. Instead, rapid cooling forces the steel into a hardened state suitable for demanding applications such as gears, shafts, and cutting tools.

Why Quenching Is Used in Steel Processing

Quenching is used because steel’s mechanical properties are highly dependent on its cooling rate after heating. Slow cooling produces ductile but softer steel, while rapid cooling dramatically increases hardness.

Manufacturers rely on quenching to:

- Improve wear resistance

- Increase load-bearing capacity

- Extend component lifespan

- Prepare steel for secondary treatments such as tempering

Without quenching, many high-performance steel components would fail prematurely under stress or friction.

The Science Behind Rapid Steel Cooling

The science of quenching lies in phase transformation and atomic diffusion control. When steel is heated above its critical temperature (typically 723–900°C, depending on carbon content), its structure changes into a phase known as austenite.

At this stage, carbon atoms are evenly distributed within the iron lattice. Quenching rapidly removes heat, preventing carbon atoms from diffusing out. As a result, the lattice collapses into a distorted structure called martensite.

Austenite to Martensite Transformation

Martensite formation is the defining scientific outcome of quenching.

- Austenite is stable only at high temperatures.

- Rapid cooling traps carbon atoms in place.

- The trapped carbon causes lattice distortion.

- This distortion produces extreme hardness.

According to research published in MDPI Metals, martensitic steel can be up to four times harder than slowly cooled pearlitic steel.

How Quenching Works: Step-by-Step Process

The quenching process follows a precise sequence to achieve consistent results:

- Austenitizing: Steel is heated to a temperature where its structure becomes fully austenitic.

- Soaking: The steel is held at this temperature to ensure uniform heat distribution.

- Rapid Cooling (Quenching): The steel is immersed in a quenching medium to extract heat quickly.

- Microstructural Lock-In: Martensite forms as diffusion is suppressed.

- Post-Quench Evaluation: Hardness, distortion, and surface integrity are inspected.

Each step must be carefully controlled to avoid defects such as cracking or warping.

Quenching Media and Cooling Severity

The choice of quenching medium directly influences cooling speed, hardness, and risk of failure.

Common Quenching Media

| Quenching Medium | Cooling Rate | Advantages | Risks |

| Water | Very fast | High hardness | Cracking, distortion |

| Brine | Extremely fast | Maximum hardness | Severe thermal shock |

| Oil | Moderate | Reduced cracking | Lower hardness |

| Polymer solutions | Adjustable | Controlled cooling | Requires monitoring |

| Air / Gas | Slow | Minimal distortion | Limited hardness |

ASM Heat Treating Society notes that incorrect medium selection is one of the leading causes of quench-related failures in industrial environments.

Heat Transfer Stages During Quenching

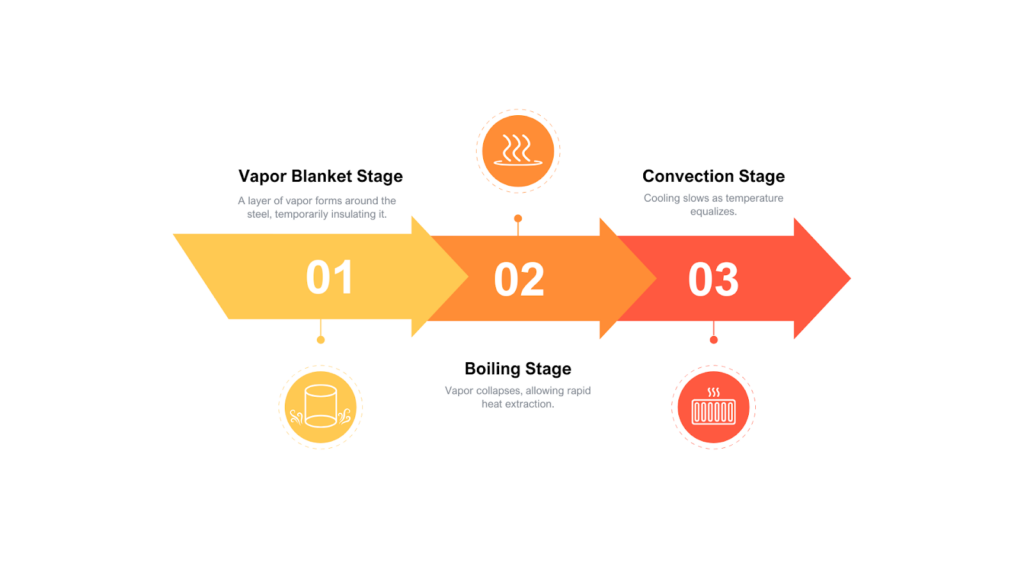

Quenching in liquid media occurs in three distinct heat transfer stages:

Understanding these stages allows engineers to fine-tune quenching systems for consistent results.

Mechanical Properties After Quenching

Quenched steel exhibits dramatic changes in mechanical performance.

Primary Property Improvements

- Increased hardness

- Improved wear resistance

- Higher tensile strength

However, these benefits come with trade-offs.

Residual Stress and Brittleness

While quenching increases hardness, it also introduces residual internal stresses. These stresses can lead to cracking if not properly managed. This is why quenching is rarely used alone and is typically followed by tempering.

Industrial Applications of Quenching

Quenching is widely used across industries that demand precision and durability.

Key Applications

- Automotive: Gears, crankshafts, suspension components

- Manufacturing: Cutting tools, dies, molds

- Construction: Structural fasteners, load-bearing elements

- Energy: Turbine shafts, drilling equipment

In automotive manufacturing alone, heat-treated and quenched steel components account for over 60% of critical drivetrain parts, as reported by industry analyses from ASM International.

Risks and Challenges of Quenching

While quenching delivers powerful benefits, it also introduces potential risks if poorly controlled.

Common Quenching Problems

- Cracking due to thermal shock

- Distortion from uneven cooling

- Surface oxidation

- Inconsistent hardness

Conclusion

Quenching is a vital heat treatment process that enables steel to achieve the hardness, strength, and durability required for demanding industrial applications. By rapidly cooling steel and controlling phase transformations, quenching allows manufacturers to precisely tailor material performance.

At Align MFG, quenching is treated as part of a fully integrated manufacturing strategy rather than a standalone step. Through careful control of materials, heat treatment parameters, and post-quench processes, Align MFG helps ensure steel components meet consistent performance standards and long-term reliability requirements.