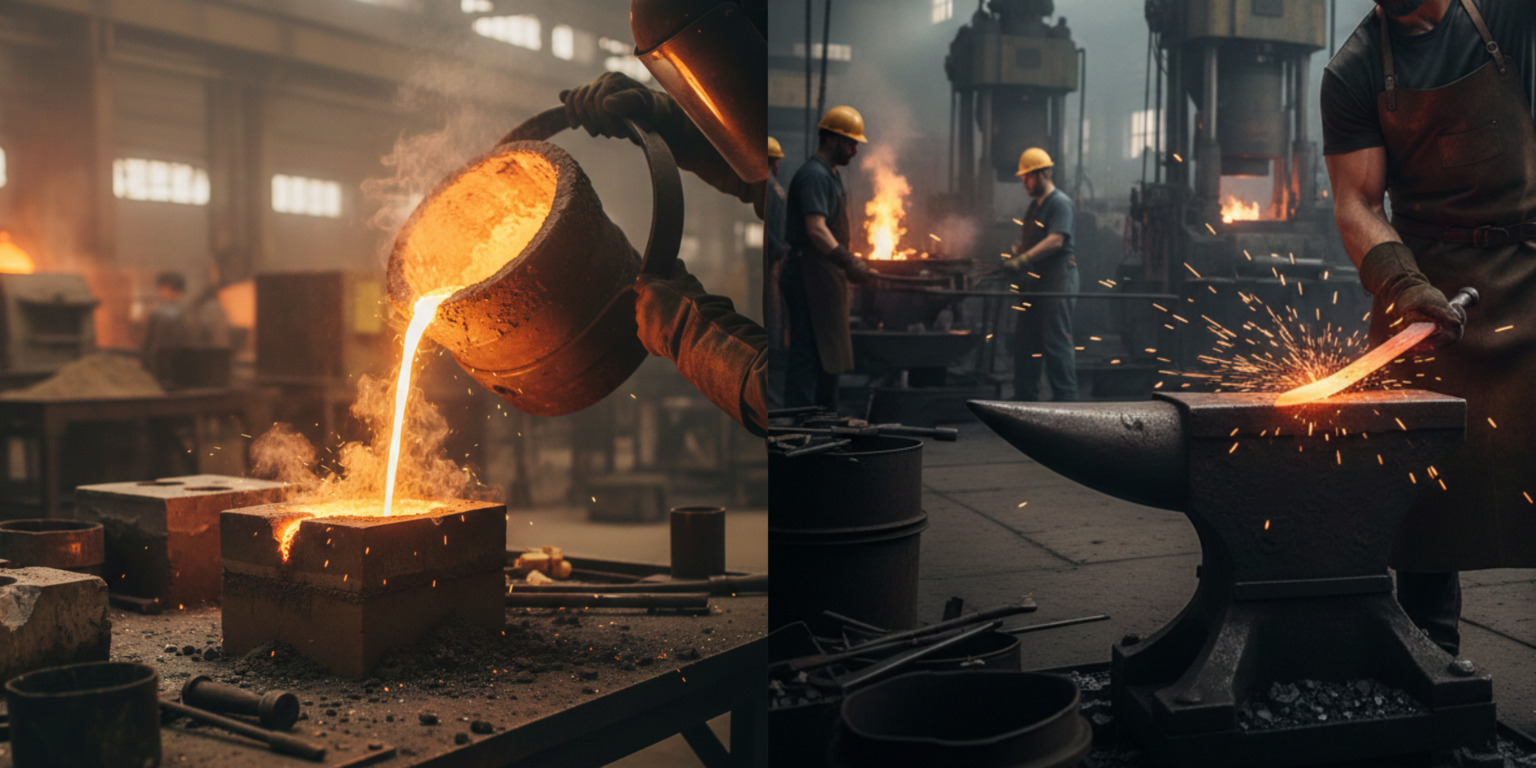

Casting vs Forging in Automotive Manufacturing: Which is Better?

In the world of automotive manufacturing, the choice of material processing methods significantly impacts the quality, performance, and cost of vehicle components. Two primary techniques, casting and forging, stand out for their unique advantages and applications. This article delves into casting and forging, comparing their processes, benefits, disadvantages, and the contexts in which each method is preferable.

What is Casting?

Casting is a manufacturing process where liquid material (usually metal) is poured into a mold to achieve a desired shape. Once the material cools and solidifies, it takes the form of the mold, allowing for intricate designs and complex geometries. The casting process includes several methods, such as sand casting, investment casting, and die casting, each with specific applications depending on the type of material and the required precision.

Key Characteristics of Casting:

- Complex Shapes: Casting can create more complex and intricate geometries that may be difficult or impossible to achieve with other manufacturing processes.

- Material Versatility: A wide range of materials can be used in casting, including aluminum, iron, and magnesium alloys.

- Scale Production: Efficient for large-scale production, especially when producing multiple parts that share identical geometries.

What is Forging?

Forging, on the other hand, involves shaping metal using localized compressive forces. This technique often employs hammers or presses to deform the metal into a desired shape. Like casting, forging also offers various methods, including open-die forging, closed-die forging, and precision forging.

Key Characteristics of Forging:

- Strength and Durability: Forged parts typically have enhanced mechanical properties due to the work-hardening of the material, offering better strength, fatigue resistance, and ductility.

- Less Waste: Forging usually results in less material waste compared to casting, as it involves deforming existing material rather than creating a new piece from molten metal.

- Lower Tolerances: Forged components often have tighter tolerances than cast parts, which can be crucial in applications where precision is key.

Comparison of Casting and Forging

When deciding whether to use casting or forging in automotive manufacturing, several factors come into play. Let’s compare the two processes based on various criteria:

1. Mechanical Properties

- Casting – The mechanical properties of cast parts can vary widely depending on the material used and the casting method employed. Generally, casting can lead to defects such as porosity and inclusions, impacting strength.

- Forging – Forged components typically exhibit superior mechanical properties such as greater strength and toughness. The process refines the internal grain structure of the metal, leading to improved performance in high-stress applications.

2. Geometric Complexity

- Casting – It excels in producing complex shapes and cavities that are difficult to achieve with forging. This makes it an excellent choice for components with intricate designs, such as engine blocks or cylinder heads.

- Forging – While forging may be limited in geometric complexity, it is more suitable for simpler, high-performance parts such as crankshafts, connecting rods, and gears.

3. Production Volume

- Casting – Best suited for large production runs due to its ability to easily replicate complex shapes. Once a mold is created, casting can be a cost-effective method for producing thousands of parts.

- Forging – Forging is often more economical for lower production volumes but can be costly for high volumes due to the machinery and tooling required for each component.

4. Material Waste

- Casting – Can produce considerable waste, especially if the design is not optimized. The excess material that does not fill the mold must be trimmed away.

- Forging – Generally incurs less waste as the bulk material is transformed into the final shape, retaining more of the original stock.

5. Cost Considerations

- Casting – The initial investment for molds can be high, but the low-cost per unit during mass production can offset this. Casting is typically the cheaper option for producing complex parts in bulk.

- Forging – The cost of manufacturing forged components can be higher due to the equipment requirements and lower production rates. However, the enhanced properties and performance of forged parts may justify the higher costs in applications where reliability is crucial.

Applications in the Automotive Industry

Both casting and forging play vital roles in automotive manufacturing, but their applications differ significantly:

Casting Applications:

- Engine blocks

- Cylinder heads

- Transmission cases

- Complex housings and brackets

Forging Applications:

- Crankshafts

- Connecting rods

- Gears

- Suspension components

Which Is Better?

There’s no single answer. The choice between casting and forging depends on application requirements, performance goals, cost constraints, and production volume:

| Criteria | Casting | Forging |

| Strength & Durability | Moderate | Excellent |

| Design Complexity | Excellent | Good |

| Cost Efficiency | Better for large runs | Higher tooling cost |

| Material Waste | Lower | Higher (but improving) |

| Production Speed | Faster | Slower |

In summary:

- Use forging for structural and high-stress components where strength matters most.

- Choose casting for complex shapes and high-volume parts where cost and flexibility are priorities.

Conclusion

In summary, both casting and forging have their advantages and disadvantages within automotive manufacturing. The choice between the two ultimately hinges on the specific needs of the application and the performance requirements of the components being made.

Additionally, the incorporation of automation in the casting process can enhance efficiency and consistency, making it a more appealing option for certain applications. By carefully evaluating these factors, manufacturers can select the most appropriate method to meet their production goals and ensure the performance of their vehicles.