Investment Casting in Vietnam: Process & Benefits

Investment casting, also known as lost-wax casting, is a versatile, cost-effective method for producing complex, high-precision metal components across industries like aerospace, automotive, medical, and industrial machinery. As companies look for reliable alternatives to traditional manufacturing hubs, Vietnam is emerging as a top destination, offering competitive costs, skilled labor, and modern capabilities. This guide explains how investment casting works, why it’s widely used, and why Vietnam is ideal for your next project.

What Is Investment Casting?

Investment casting is a precision metal-forming process that uses a wax pattern to create a ceramic mold, into which molten metal is poured to produce complex parts with excellent surface finish and tight tolerances. Because the mold is destroyed after each casting, the process is ideal for intricate geometries, thin walls, and near-net-shape components that would be difficult or expensive to machine.

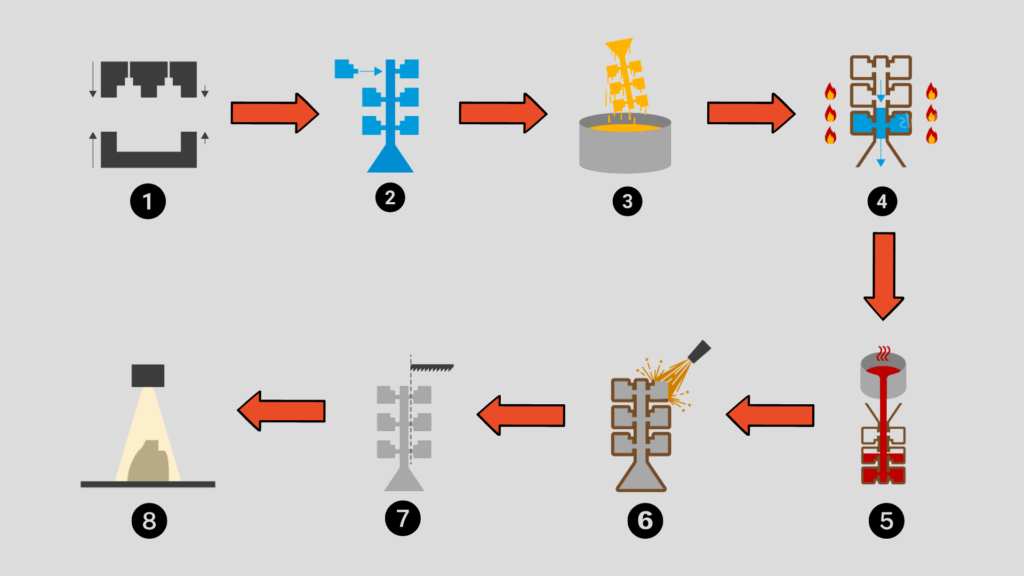

Step-by-Step: How the Investment Casting Process Works

1. Wax Pattern Creation

The process starts with creating a wax replica of the final part. This pattern is typically made by injecting molten wax into a metal die. If the part is complex, multiple wax sections are assembled together.

2. Assembly (Treeing)

Multiple wax patterns can be attached to a central wax sprue, forming what’s known as a “tree.” This allows multiple components to be cast in a single batch, improving efficiency.

3. Ceramic Shell Building

The wax tree is repeatedly dipped into a ceramic slurry and coated with fine sand. After each layer dries, the process is repeated several times to build a strong ceramic shell capable of withstanding high casting temperatures.

4. Dewaxing

Once the ceramic shell is complete, the wax is melted and drained out, leaving a hollow mold cavity that precisely mirrors the original part geometry.

5. Metal Pouring

The preheated ceramic mold is filled with molten metal under carefully controlled conditions. The choice of alloy depends on the application, ranging from stainless steel and carbon steel to cobalt- or nickel-based superalloys.

6. Cooling and Shell Removal

After the metal solidifies, the ceramic shell is broken away, revealing the raw cast part.

7. Cutting, Finishing & Inspection

Individual castings are cut from the tree and undergo finishing processes like grinding, machining, heat treatment, and surface finishing.

8. Inspection

Rigorous inspections (including dimensional checks, NDT, and chemical analysis) ensure the final components meet all specifications.

Why Choose Investment Casting?

- Complex Geometry & Design Freedom

Because the wax pattern can replicate almost any shape, investment casting allows for intricate designs with fine details, thin walls, undercuts, and internal cavities without expensive tooling changes.

- Superior Surface Finish

The ceramic mold delivers a smooth surface straight out of the casting process, significantly reducing or even eliminating secondary machining and polishing.

- Material Versatility

Investment casting supports a wide range of metals and alloys (stainless steel, aluminum, titanium, cobalt-chrome, and more) enabling engineers to meet demanding performance and environmental requirements.

Why Vietnam Is Becoming a Top Choice for Investment Casting

1) Cost-Effective Manufacturing

Vietnam’s lower labor costs, often 30–50% below China, translate into highly competitive pricing without compromising quality. Combined with efficient operations and favorable logistics, buyers often achieve significant cost savings per unit.

2) Skilled Workforce & Industrial Growth

Vietnam’s rapid industrialization has been accompanied by a focus on technical training and manufacturing excellence. Many foundries now operate with modern equipment, ISO certifications, and experienced engineering teams.

3) Strategic Location & Trade Advantages

With free trade agreements like the CPTPP and EVFTA, Vietnam enjoys preferential access to major markets in the U.S., EU, and Asia. Its proximity to global supply chain hubs also reduces shipping times and logistics costs.

4) Advanced Capabilities

Vietnamese foundries have invested heavily in advanced casting technology, from 3D-printed wax patterns to automated shell building, enabling them to produce high-precision components for demanding industries.

5) Flexible Production Volumes

From low-volume prototype runs to high-volume production, investment casting facilities in Vietnam offer scalability that suits both startups and global OEMs.

Industries That Rely on Investment Casting in Vietnam

- Aerospace: Turbine blades, brackets, housings

- Automotive: Turbocharger components, suspension parts

- Energy: Pump bodies, valve components, impellers

- Medical: Surgical instruments, implantable components

- Industrial Equipment: Tooling, wear-resistant parts, machine housings

Conclusion

Investment casting remains one of the most powerful manufacturing methods for producing high-quality metal components with precision and design flexibility. As companies rethink their sourcing strategies in a globalized landscape, Vietnam stands out as a smart, strategic choice, combining cost advantages with technical expertise, modern facilities, and strong quality standards.Ready to explore investment casting solutions in Vietnam? Align Manufacturing’s engineering team can support your project from concept to completion, helping you bring high-quality, cost-effective components to market faster.