Friend-shoring, Near-shoring, Reshoring, and Other Buzzwords

Supply chain landscape is evolving rapidly, fueled by shifting geopolitics, emerging technologies, and changing consumer demands. Terms like friend-shoring, near-shoring, and re-shoring are gaining traction as businesses seek to adapt. But what do these buzzwords mean, and how do they impact global supply chain strategies?

In this article, we'll explore these key concepts, compare their benefits, challenges, and applications, and provide actionable insights for supply chain professionals. By the end, you'll understand why companies like Align Manufacturing are leading the way in navigating these trends.

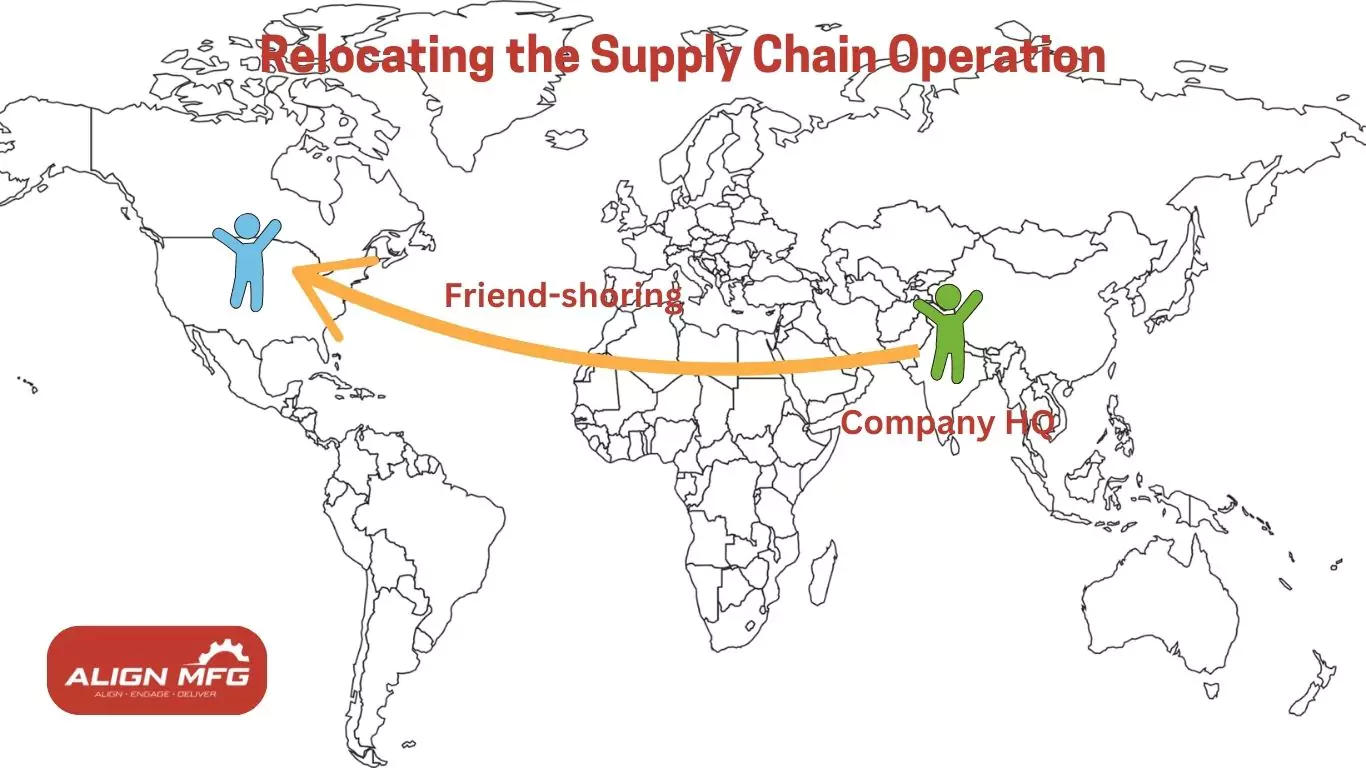

What is Friend-shoring?

Friend-shoring is the strategic relocation of supply chains to countries that share aligned political, economic, or ideological interests. This emerging approach addresses growing concerns over geopolitical risks, fostering economic collaboration among nations that are considered reliable allies.

Key Objectives of Friend-shoring:

- Mitigating Risks: By focusing on countries with stable governance and aligned values, businesses minimize the risk of trade disruptions caused by geopolitical tensions.

- Strengthening Alliances: Encourages mutual economic growth and reinforces trust among allied nations.

- Reducing Overdependence: Diversifies supply chains, reducing reliance on politically unstable or adversarial countries.

Benefits of Friend-shoring:

- Reduced Geopolitical Risks: Relocating supply chains to trusted countries ensures continuity even during global tensions.

- Improved Economic Collaboration: Aligning trade policies and practices fosters smoother operations and better partnerships.

- Examples in Action: Semiconductor manufacturers are a notable example, shifting production to countries within alliances like NATO to reduce dependency on regions with volatile relations, such as China.

Challenges of Friend-shoring:

- Finding Reliable Partners: Evaluating a nation’s infrastructure, workforce skills, and regulatory environment is critical.

- Regulatory Variations: Even allied countries may have differing legal frameworks, complicating compliance.

- Cost Implications: While offering political stability, these shifts may incur higher costs compared to traditional offshoring.

Friend-shoring is gaining momentum as nations and businesses aim to build resilient supply chains in the face of geopolitical instability. Its focus on allied nations offers a pragmatic solution for long-term sustainability.

Exploring Near-shoring

Near-shoring refers to the relocation of supply chain operations closer to a company’s home market. This strategy improves operational efficiency by reducing transportation costs and delivery times, offering an agile response to market demands.

Core Principles of Near-shoring:

- Proximity: Operating closer to key markets reduces time-to-market.

- Cost Efficiency: While not as low-cost as offshoring, reduced logistics expenses offset higher labor costs.

- Supply Chain Agility: Faster access to resources and production facilities enhances adaptability.

Benefits of Near-shoring:

- Faster Delivery Times: Shortened supply chains mean quicker access to products for consumers.

- Reduced Transportation Costs: Geographic proximity lowers shipping and storage expenses.

- Enhanced Collaboration: Being closer geographically often fosters better communication and understanding with suppliers.

Real-World Applications:

- Example: Many U.S. companies are opting to shift operations to Mexico rather than Asia to save on costs and reduce transit delays.

- Case Study: A North American electronics manufacturer reported a 40% decrease in delivery times after relocating operations to Mexico, allowing them to better compete with local rivals.

Challenges of Near-shoring:

- Labor Costs: Though lower than home markets, labor costs are often higher than traditional offshoring destinations.

- Infrastructure Readiness: Some near-shore countries may lack adequate infrastructure, leading to bottlenecks.

- Supplier Availability: Limited availability of specialized suppliers in certain regions can hinder progress.

Near-shoring is a middle-ground strategy, balancing operational proximity with cost efficiency, making it an attractive option for many industries.

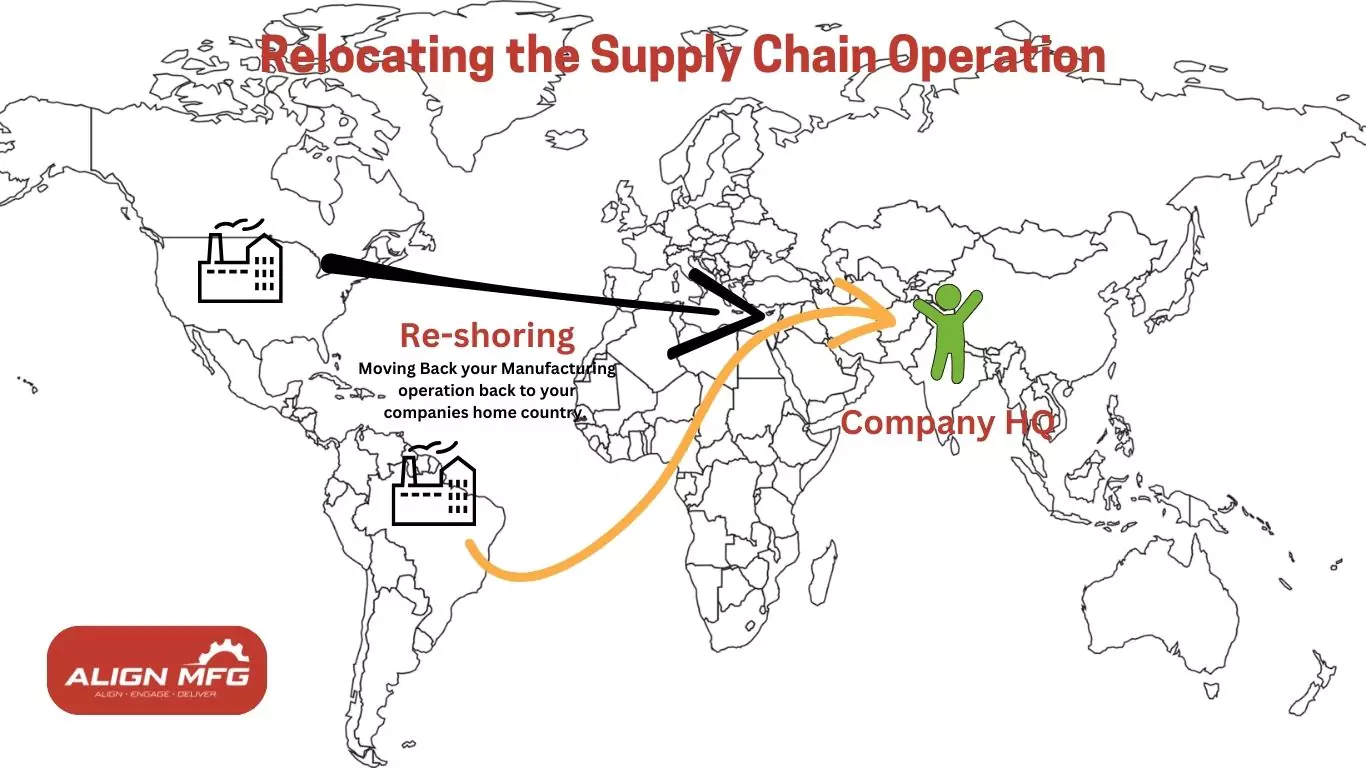

Re-shoring: Bringing It Home

Re-shoring, also called onshoring, involves moving manufacturing or production processes back to the company’s home country. This strategy emphasizes boosting domestic economic activity, enhancing brand reputation, and reducing external dependencies.

Why Companies are Re-shoring:

- Government Incentives: Many governments provide tax breaks, grants, or subsidies to encourage businesses to bring operations back home.

- Consumer Demand: “Made in the USA” or similar homegrown labels resonate strongly with consumers, fostering trust and brand loyalty.

- Supply Chain Stability: By operating domestically, businesses avoid global shipping uncertainties and reduce overreliance on external suppliers.

Benefits of Re-shoring:

- Job Creation: Brings employment opportunities back to domestic markets.

- Improved Quality Control: Having production closer allows for stringent oversight and quality assurance.

- Enhanced Resilience: Reduces the risk of disruptions caused by international supply chain interruptions.

Examples in Practice:

- Apple: While much of its manufacturing remains overseas, Apple has partially re-shored some production of key components to the U.S., ensuring compliance with local quality standards.

- Boeing: Relocated significant operations back to U.S. soil to address concerns over outsourcing quality and supply chain resilience.

Challenges of Re-shoring:

- Higher Costs: Domestic labor is generally more expensive compared to traditional offshore or near-shore options.

- Logistical Complexity: Transitioning existing supply chains to domestic locations involves significant planning and investment.

- Scaling Issues: Home markets may lack the resources or infrastructure to support large-scale operations in certain industries.

Re-shoring is often seen as a long-term investment, prioritizing quality, reliability, and local economic growth over immediate cost savings.

Offshoring: The Precursor

Offshoring refers to outsourcing production or services to countries with lower labor and operational costs. This practice, dominant in the late 20th century, was a cornerstone of globalization and remains a key strategy for cost reduction.

Why Offshoring Became Popular:

- Cost Savings: Access to cheaper labor markets and lower production costs made offshoring highly lucrative.

- Scalability: The ability to rapidly scale operations in manufacturing hubs like China or India.

- Global Markets: Many companies capitalized on both low production costs and new consumer markets in these regions.

Benefits of Offshoring:

- Significant Cost Reductions: Labor and operational expenses are substantially lower in many developing nations.

- Increased Capacity: Access to a larger, cost-effective workforce allows companies to expand rapidly.

- Global Reach: Establishing a presence in foreign markets often aligns with the growth of a global consumer base.

Current Challenges with Offshoring:

- Supply Chain Disruptions: Events like COVID-19 exposed vulnerabilities in relying on global supply chains.

- Reputation Concerns: Companies face criticism over ethical concerns, such as poor labor conditions in certain regions.

- Geopolitical Risks: Trade wars, sanctions, and international conflicts can severely impact operations.

While offshoring remains a vital strategy for many businesses, its drawbacks are causing companies to reconsider alternative approaches, such as near-shoring and friend-shoring, to mitigate risks and improve resilience.

Benefits of These Strategies

| Strategy | Cost | Risk Mitigation | Delivery Speed |

| Friend-shoring | Moderate | High | Moderate |

| Near-shoring | High | High | High |

| Re-shoring | Highest | Very High | Highest |

Current Trends in Supply Chain Strategies

Modern strategies emphasize regionalization, automation, and sustainability. For example:

- Digital twins for monitoring supply chains.

- Blockchain for transparency.

- Geopolitical events like Brexit are increasing regionalization efforts.

Future Predictions

The future of supply chain management will likely see:

- Increased investment in technology like AI for forecasting.

- Expansion of regional trade networks.

Role of Align Manufacturing in Supporting Strategies

Align Manufacturing offers expertise in simplifying these transitions by:

- Streamlining logistics through technology.

- Providing end-to-end supply chain solutions tailored to business needs.

Why Align Manufacturing is Your Partner

With its expertise in supply chain optimization, Align Manufacturing helps businesses stay ahead in a volatile global market. Their custom solutions, supported by cutting-edge technology, ensure smooth implementation of these strategies.

Conclusion

Adapting your supply chain strategy isn’t just a competitive advantage—it’s a survival necessity. Approaches like friend-shoring, near-shoring, and re-shoring enable businesses to enhance resilience, optimize costs, and strengthen their market positioning. However, each strategy comes with unique benefits and challenges, requiring careful evaluation to align with your business goals.

Companies like Align Manufacturing make navigating these transitions seamless, leveraging their expertise in supply chain optimization and cutting-edge technology to craft tailored solutions. Whether you’re mitigating risks, reducing delivery times, or enhancing supply chain agility, Align Manufacturing is your trusted partner for turning strategy into success.