High-Pressure Die Casting in Vietnam: Future Trends to Watch

High-pressure die casting (HPDC) has been the backbone of modern manufacturing for decades, producing everything from automotive housings and engine components to consumer electronics frames and intricate industrial parts. But the process, while mature, is far from static. Around the world and especially in Vietnam, high-pressure die casting is undergoing a major transformation, driven by evolving customer demands, rapid advances in technology, and a new focus on sustainability and efficiency.

This article breaks down the key technologies, trends, and strategies shaping the future of die casting, and how partnering with the right supplier can give your business a decisive edge.

Why High-Pressure Die Casting is Changing

The basic principles of HPDC remain the same: molten metal (usually aluminum, zinc, or magnesium) is injected under high pressure into a steel mold to produce complex, dimensionally precise parts at scale. But the global manufacturing landscape around it has shifted dramatically in the past few years.

Several key factors are driving innovation in HPDC:

- Lightweighting and performance. Automotive, EV, and aerospace sectors demand lighter components without compromising strength.

- Sustainability. Global customers and regulators are pushing for greener processes, less waste, and lower energy consumption.

- Digitalization. Industry 4.0 technologies (sensors, data analytics, and digital twins) are reshaping how factories operate.

- Cost and speed pressures. Shorter development cycles, higher quality expectations, and global competition mean manufacturers must deliver more, faster.

1. Digital Twin Technology and Simulation-Driven Design

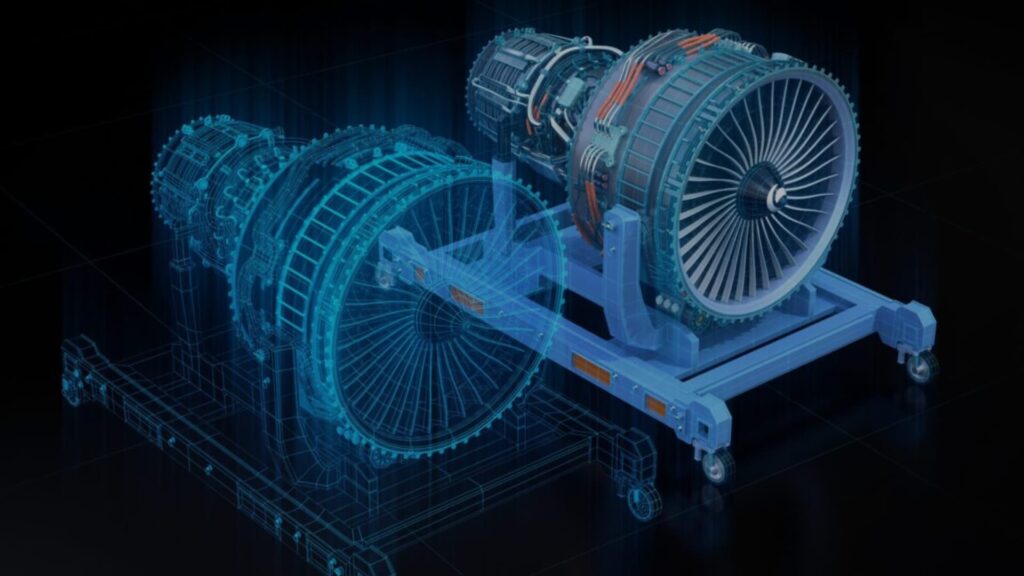

One major advancement in die casting is the use of digital twin technology, virtual models that simulate real casting processes. With advanced software, engineers can predict defects, test tooling, and optimize designs before building physical molds. This helps catch issues like porosity or warpage early, reducing trial and error, speeding up development, and cutting costs.

In Vietnam, more die casting suppliers are investing in these powerful simulation tools, which enable closer collaboration with clients right from the design phase. The result is not only higher-quality parts but also smoother development cycles, shorter lead times, and reduced project risks.

2. Smart Factories, Automation, and Robotics

Automation is now essential in high-pressure die casting. Modern lines use robotics for metal feeding, spraying, part removal, trimming, and quality checks, while sensor-driven controls boost precision. This leads to better quality, faster cycle times, and safer operations.

In Vietnam, die casting facilities are quickly embracing these technologies, often using advanced European or Japanese equipment. As a result, manufacturers sourcing parts from Vietnam can now access world-class quality, high scalability, and competitive lead times, all while benefiting from significantly lower costs compared to traditional die casting hubs like China or Germany.

3. Advanced Alloys and Lightweight Materials

Material science is increasingly shaping die casting as industries seek stronger, lighter, and more durable parts. New aluminum, zinc, and magnesium alloys deliver improved performance, from lightweight magnesium for EVs and aerospace to high-strength aluminum for thin, strong components and custom blends tailored to specific needs.

In Vietnam, suppliers that once focused mainly on standard alloys like A380 and ADC12 are now expanding their capabilities to include these advanced materials. This shift is empowering manufacturers to create next-generation components locally. Combining innovation, performance, and cost efficiency in a single sourcing destination.

4. Smarter Surface Finishing and Post-Processing

Casting is only half the story. Finishing determines how a part performs and looks. Modern post-processing like automated deburring, polishing, anodizing, and specialty coatings improves quality, cuts costs, and achieves tighter tolerances.

For buyers, these innovations mean fewer secondary suppliers, lower logistics costs, and faster delivery of ready-to-use components. In Vietnam, many die casting facilities now provide turnkey solutions (offering everything from casting to coating under one roof) making sourcing simpler, faster, and more cost-effective.

5. Real-Time Monitoring and Data Analytics

One of the most transformative shifts in high-pressure die casting in Vietnam is the adoption of real-time process monitoring and data analytics. Many local facilities now embed sensors in machines to track cavity pressure, mold and melt temperature, cooling rates, and injection speed. This data is analyzed to detect deviations, prevent defects, and even predict maintenance needs before downtime occurs.

The result is higher yields, more consistent quality, and improved production insight. For international buyers sourcing from Vietnam, these technologies provide greater traceability and confidence, ensuring that locally produced parts meet strict global standards reliably and efficiently.

The Future Of Die Casting in Vietnam

The next five years will redefine what’s possible in die casting, and Vietnam is poised to lead that evolution. As the industry embraces innovations in high pressure die casting Vietnam, manufacturers are focusing on greater precision, automation, and performance efficiency. We’re entering a new era where data-driven manufacturing, sustainability, and advanced materials are as important as cost and capacity. At AlignMFG, we combine advanced high-pressure die casting capabilities with cutting-edge technology, world-class quality control, and a customer-first approach. Whether you’re designing next-generation EV components, lightweight industrial enclosures, or high-precision consumer products, our team in Vietnam can help you bring your project to life.