Steel is one of the most versatile materials used across various industries, from construction to automotive manufacturing. Its unique physical properties can be significantly altered through various treatment processes, primarily hardening and tempering. Understanding these two treatments is crucial for selecting the right material for specific applications. In this article, we will explore what hardening…

Ductile iron, also known as nodular iron or spheroidal graphite iron, is a type of cast iron known for its high strength, toughness, and durability. It combines the castability and cost advantages of traditional cast iron with mechanical properties closer to steel, making it a popular material across many industries. This article explains what ductile…

In the world of automotive manufacturing, the choice of material processing methods significantly impacts the quality, performance, and cost of vehicle components. Two primary techniques, casting and forging, stand out for their unique advantages and applications. This article delves into casting and forging, comparing their processes, benefits, disadvantages, and the contexts in which each method…

Quenching is a fundamental heat treatment process in metallurgy that involves the rapid cooling of steel after it has been heated to a high temperature. This sudden temperature change alters the steel’s internal structure, significantly improving properties such as hardness, strength, and wear resistance. According to ASM International, quenching is one of the most widely…

Stainless steel magnetism depends largely on its internal crystal structure and alloy composition, not simply on the presence of iron. While many people assume all stainless steel is non-magnetic, the reality is more nuanced. Some stainless steel grades are magnetic, while others are not. This distinction is primarily driven by whether the material is ferritic…

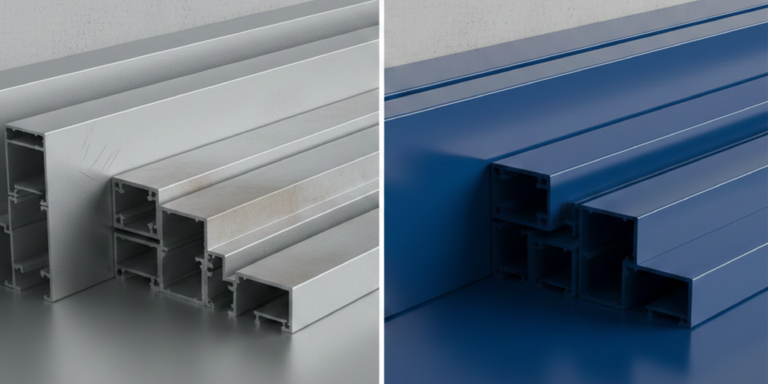

Anodizing and powder coating are two of the most widely used metal finishing processes for improving durability, corrosion resistance, and appearance. Anodizing is an electrochemical process that transforms the metal surface itself, while powder coating applies a protective polymer layer on top of the metal. According to manufacturing and architectural finishing data, surface treatments can…

1045 carbon steel is a medium-carbon steel grade widely used in engineering and manufacturing due to its balanced combination of strength, toughness, and machinability. Containing approximately 0.43–0.50% carbon, it offers significantly higher strength than low-carbon steels while remaining cost-effective and versatile. This guide explains what 1045 carbon steel is, its chemical and mechanical properties, how…

Austenitic stainless steel is a widely used class of stainless steel known for its exceptional corrosion resistance, strength, and versatility across industries. It is characterized by a face-centered cubic (FCC) crystal structure stabilized primarily by chromium and nickel, making it suitable for demanding environments such as food processing, marine, medical, and chemical applications. According to…

The lost wax casting process—also known as investment casting—is a manufacturing technique used to produce highly detailed metal components by creating a disposable wax model that is replaced with molten metal. This method has been used for over 6,000 years, from ancient bronze sculptures to modern aerospace and medical components, due to its ability to…

When companies look beyond traditional manufacturing hubs, they increasingly discover that Vietnam gravity casting offers a uniquely advantageous mix of cost, capability, and flexibility. As global demand grows for precision-cast metal parts, Vietnam is quietly emerging as a go-to destination. In this article, we explore why gravity casting in Vietnam deserves more attention than it…