Posts by Casey Ross

Align MFG Vietnam Expands Global Footprint with New Strategic Office in Hồ Chí Minh

Align Manufacturing proudly announces the expansion of its global operations with the opening of its new Align MFG Vietnam strategic office at Nguyễn Văn Luông, Phường 12, Quận 6, in former District 6, Hồ Chí Minh City. This three‑story facility, located just three minutes from the Vòng Xoay Phú Lâm–27A Kinh Dương Vương bus stop, is designed to enhance operations, quality control, logistics, inspection, and sourcing, all under one roof. Featuring a meeting room, employee lounge, and balcony space, it reflects Align’s commitment to operational excellence in a thriving regional hub.

Prime Location: District 6, Phú Lâm Intersection and Connectivity

Directly adjacent to the bustling Phú Lâm rotary and within minutes of key arterial roads like Kinh Dương Vương, the new office lies in a strategic logistics corridor of Ho Chi Minh City. The area bridges the city center with major industrial zones, and lies near Saigon Port, Vietnam’s busiest container port and a key gateway for southern exports.

Since the July 1, 2025 merger, Ho Chi Minh City expanded to annex former Bình Dương and Bà Rịa–Vũng Tàu provinces, elevating its role as Vietnam’s top industrial and trade hub. District 6 offers easy access to major highways and inland logistic corridors, providing fast connections westward toward Trung Luong Expressway and southward to the Mekong Delta.

Office Design & Facilities: Collaboration, QC, Logistics Hub

The three‑level layout enhances both efficiency and employee experience. On the ground floor, the logistics and inspection teams operate with direct receipt and outgoing shipments flow. The middle floor houses quality control, inspection bays, and sourcing coordination, facilitating data-driven decision-making. The top floor includes a meeting room for clients and partners, a balcony overlooking the neighborhood, and a lounge area that fosters employee engagement.

By centralizing operations, Align MFG ensures faster feedback loops, tighter quality control, and streamlined processes, ideal for high-margin industries where responsiveness and precision matter.

Why Vietnam: Manufacturing Growth, Trade Diversification, Strategic Hub

Vietnam’s manufacturing sector contributes over 20% of GDP, and in 2022 alone industrial output grew nearly 9% year-over-year despite pandemic challenges. As of mid‑2025, manufacturing and construction employed 17.4 million workers, accounting for 33.4% of total national employment.

Vietnam raised its 2025 GDP growth goal from 6.5% to between 7% and 8%, fueled by stronger manufacturing output and foreign direct investment, especially in processing-related industries.

Foreign investment continues to pour in: by Q3 2024, manufacturing and processing accounted for ~63% of total FDI (≈ US $17.5B). And in the first half of this year FDI reached $21.5B a 36.2% rise year on year.

Align MFG’s Manufacturing Excellence: Smart Processes and High Standards

Align MFG is positioning itself at the forefront of Vietnam’s manufacturing shift into Industry 4.0. The national strategy accelerates adoption of AI, IoT, data analytics, and automation to modernize production lines. The domestic smart manufacturing market, valued at US $116.8 billion in 2024, is projected to grow at 10.7% CAGR through 2033, reaching nearly US $304 billion.

Within Vietnam, smart factories integrate lean manufacturing driven by AI-enabled SOPs and real-time monitoring, delivering measurable gains in productivity and defect reduction.

Vietnam’s major industrial hubs are transforming into smart industrial parks. Notably:

- Saigon Hi‑Tech Park (HCMC) is a dedicated high‑technology cluster just 15 km from downtown, hosting global leaders like Intel and Nidec, integrating digital connectivity and streamlined customs support for chip assembly and advanced electronics work.

- VSIP III (Bình Dương) stands out with its 50-hectare solar farm, closed‑loop wastewater systems, smart logistics networks, and carbon‑neutral target factories with LEGO’s global first located here.

- Amata Long Thanh (Đồng Nai) is built from the ground up on eco-IP principles, combining Industry 4.0-ready infrastructure with resource-efficient planning, renewable power, and ESG-aligned facilities.

- WHA Industrial Zone (Nghe An) offers smart utilities, real-time environmental monitoring, blockchain energy solutions, and biotech-enabled water treatment, all designed to meet global eco-industrial standards.

Vietnam’s government supports digital transformation through wide deployment of 5G networks in industrial parks, enabling autonomous inspection robots, edge computing, and real-time monitoring systems which are crucial for precision operations in sectors like semiconductors and electronics.

Smart industrial parks also lead in circular economy approaches. Pilot zones implemented with UNIDO support have collectively saved significant energy and water, reused resources, and cut CO₂ emissions, all while enabling businesses to scale sustainably.

Target Industries: Electronics, Semiconductors, Textiles & EV Components

Vietnam’s electronics sector has emerged as a powerhouse, generating $134.5 billion in exports in 2024, and reaching $60.8 billion by May 2025, representing a 39% year‑on‑year growth. It ranks as the world’s fifth-largest exporter of electronics and computer components, second in mobile phone and parts exports.

The country currently hosts over 174 FDI projects in semiconductors and packaging, positioning Vietnam as a rising global chip ATP hub. Major investors like Amkor Technology and Hana Micron are investing billions, aiming to push Vietnam’s global chip packaging share from 1% in 2022 to 8–9% by 2032.

Additional industrial sectors such as textiles, garments, and emerging EV components are also expanding steadily, supported by growing FDI and domestic capabilities. Align MFG’s QC-inspection-sourcing model aligns well with the precision requirements of these high-value sectors.

Supply Chain & Logistics Advantage: Proximity to Markets & Infrastructure

The new Ho Chi Minh City office is strategically placed near Saigon Port and arterial roads like Kinh Dương Vương, bridging city manufacturing hubs to inland waterways and industrial zones. Vietnam operates 44 seaports, handling up to 500 million tonnes annually, and 22 airports (12 international) to support global exports.

Regionally, the Mekong Delta logistics market alone is forecast to reach US $7.8 billion in 2025, growing to $12.5 billion by 2030 at ~8.2% CAGR. The government is expanding expressways, targeting multi-hundred kilometers connecting Delta routes, and modernizing inland waterway transport to boost export efficiency.

Total Vietnamese logistics costs remain high, estimated at 18–20% of GDP, compared to a global average of ~10.6%. Yet, Align MFG’s close-in urban location allows it to mitigate transport inefficiencies, reduce lead times, and maintain tighter control across operations.

Strategic Positioning: Vietnam as China-Plus-One Supply Chain Hub

With increasing trade tensions and supply chain realignment, global manufacturers are shifting operations from China to more stable and cost-effective locations. Vietnam has benefited disproportionately, surpassing India in capturing these relocations. It now serves as a preferred alternative, backed by central planning, streamlined regulation, and a proven track record with companies like Samsung, Intel, and Apple.

Vietnam’s electronics output, $134.5 billion in 2024, is more than triple the size of India’s comparable sector despite population differences, underscoring the country’s manufacturing efficiency and export orientation.

However, geopolitical uncertainty remains: agreed U.S. tariffs of 20% on Vietnamese exports and 40% on goods shipped through Vietnam, highlight inherent trade risk. Despite that, Vietnam’s low labor costs, improving infrastructure, and manufacturing momentum continue to attract major investments.

Align MFG’s Vision and Vietnam’s Smart Manufacturing Trajectory

Vietnam’s transition to smart manufacturing is gathering pace. Digital technologies, IoT, robotics, AI-enabled SOPs, are being integrated into inspection, analytics, and sourcing workflows. The smart manufacturing market, already valued at $116.8 billion in 2024, is projected to grow at 10.7% CAGR through 2033.

Align MFG Vietnam’s office is designed to support this evolution by connecting clients to reliable and affordable manufacturing solutions for projects of all sizes.

Looking ahead, Align is positioned to deepen partnerships with key players in electronics, EV components, and precision industries flowing through Ho Chi Minh City’s manufacturing corridors. The office also places Align at the junction of expanding transport projects, like the Trung Lương‑Mỹ Thuận and Mỹ Thuận–Cần Thơ expressways, enhancing access to the Mekong Delta corridor and export nodes.

By leveraging proximity to cutting-edge smart industrial parks, efficient logistics infrastructure, and rapidly expanding high-tech sectors, Align MFG is positioned to drive superior value for partners and clients alike. This strategic presence in Ho Chi Minh City affirms Align’s commitment to innovation, collaboration, and excellence, reinforcing its role as a pivotal player in Vietnam’s journey toward becoming a global manufacturing powerhouse.

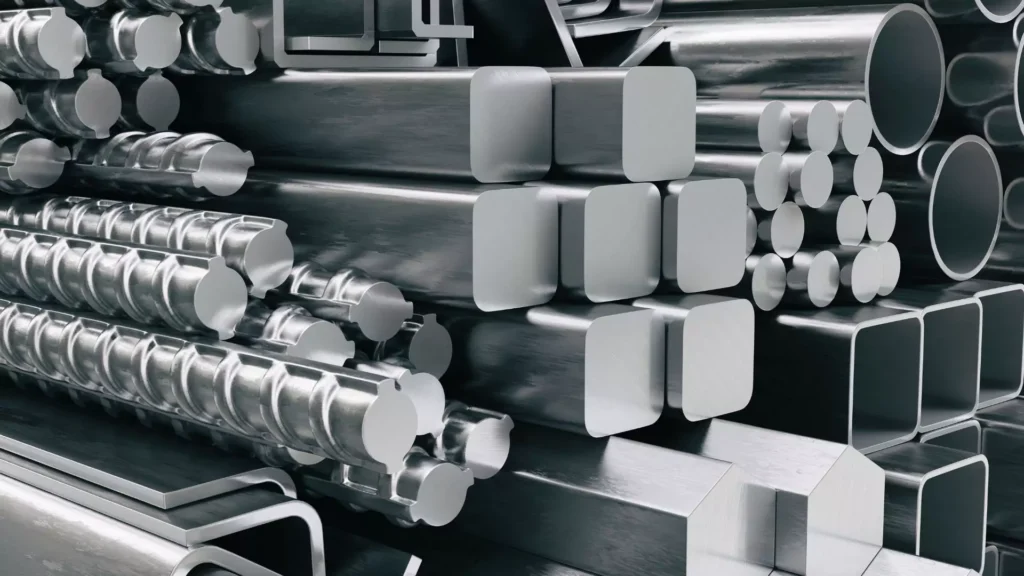

Grades of Stainless Steel: Types, Properties, and Applications

Stainless steel is a versatile and corrosion-resistant alloy composed primarily of iron, chromium, and other elements such as nickel, molybdenum, and carbon. Its unique properties make it indispensable across various industries, including construction, automotive, medical, and kitchenware. The specific grades of stainless steel determine their mechanical properties, corrosion resistance, and suitability for particular applications.

Stainless steel, a family of iron-based alloys, is distinguished by its resistance to corrosion. This resistance stems from the formation of a stable passive layer, which shields the underlying metal from the effects of air and moisture, unlike other ferrous alloys.. This rust resistance makes it a preferred material for many applications, including outdoor structures, aqueous environments, food service, and high-temperature uses.

How Is Stainless Steel Made?

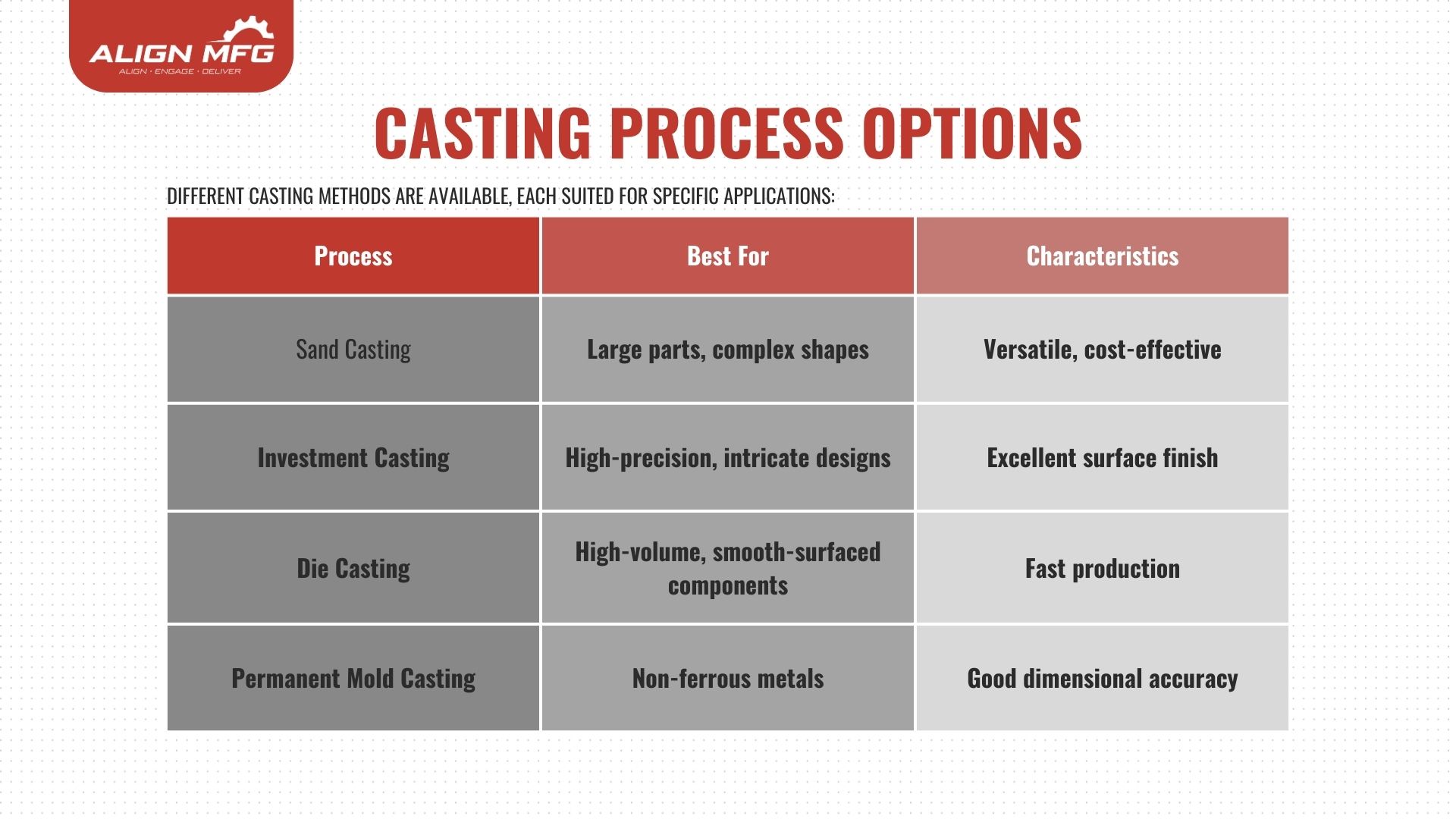

Stainless steel can be cast or wrought, with the key difference being how it is formed into the final product.

- Cast stainless steel is produced by pouring liquid metal into a mold to create a specific shape.

- Wrought stainless steel starts at a steel mill, where it is processed into ingots, blooms, billets, or slabs before being shaped further through rolling or hammering.

Wrought stainless steel products are far more common than cast stainless steel products because of their superior strength, versatility, and wide range of applications.

Production Steps of Stainless Steel

- Raw Material Selection

- Stainless steel is made from iron, carbon, and chromium (minimum 10.5%) along with other alloying elements like nickel, molybdenum, and manganese.

- Melting and Alloying

- The raw materials are melted in an electric arc furnace (EAF) at high temperatures (over 1600°C).

- Elements like nickel and molybdenum are added for enhanced corrosion resistance and strength.

- Casting into Forms

- The molten stainless steel is cast into semi-finished forms:

- Ingots (for forging and machining)

- Billets (for long products like bars and rods)

- Slabs (for flat products like sheets and plates)

- The molten stainless steel is cast into semi-finished forms:

- Hot Rolling and Cold Rolling

- The cast stainless steel is then shaped through hot rolling (above recrystallization temperature) or cold rolling (for smoother finishes and greater strength).

- Heat Treatment (Annealing)

- Annealing improves ductility and corrosion resistance by softening the material and removing internal stresses.

- Descaling & Pickling

- After rolling, stainless steel undergoes pickling, where an acid bath removes oxide scales that form during heat treatment.

- Finishing & Fabrication

- Final processes include polishing, grinding, or coating to enhance corrosion resistance and aesthetics.

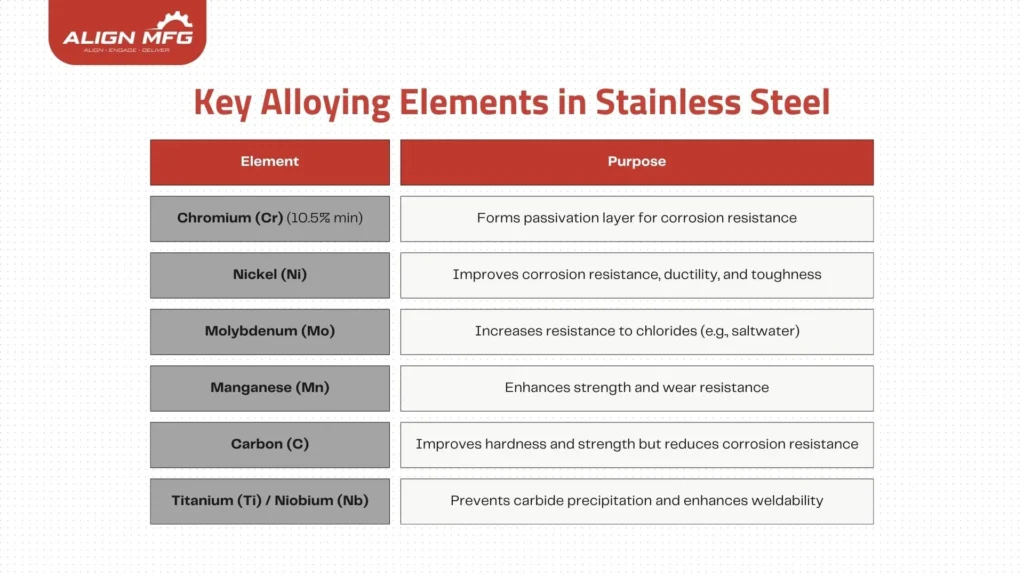

2. What Is Stainless Steel Made Of?

Like all steel, stainless steel starts with iron and carbon. However, its key differentiator is the addition of chromium (Cr), which provides its corrosion resistance.

When stainless steel is exposed to oxygen, the chromium reacts to form a thin passivation layer of chromium (III) oxide (Cr₂O₃). This layer:

- Prevents oxidation (rust)

- Self-heals when scratched, unlike plated metals (e.g., zinc-plated steel, which loses its protection if scratched)

Download our guide to understand the different grades of stainless steel.

Understanding the Microstructures and Technical Aspects of Stainless Steel

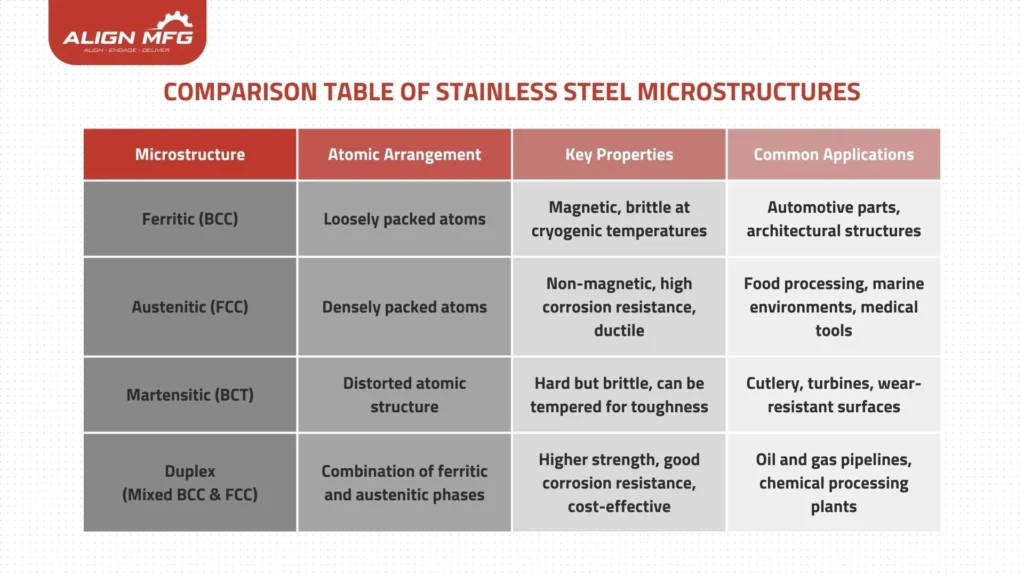

When stainless steel solidifies from its molten state, it forms distinct microstructures that dictate its mechanical properties. The interplay of temperature, elemental composition, and cooling rate influences the crystalline lattice within the steel, leading to variations in strength, ductility, and magnetism.

Microstructural Evolution in Stainless Steel

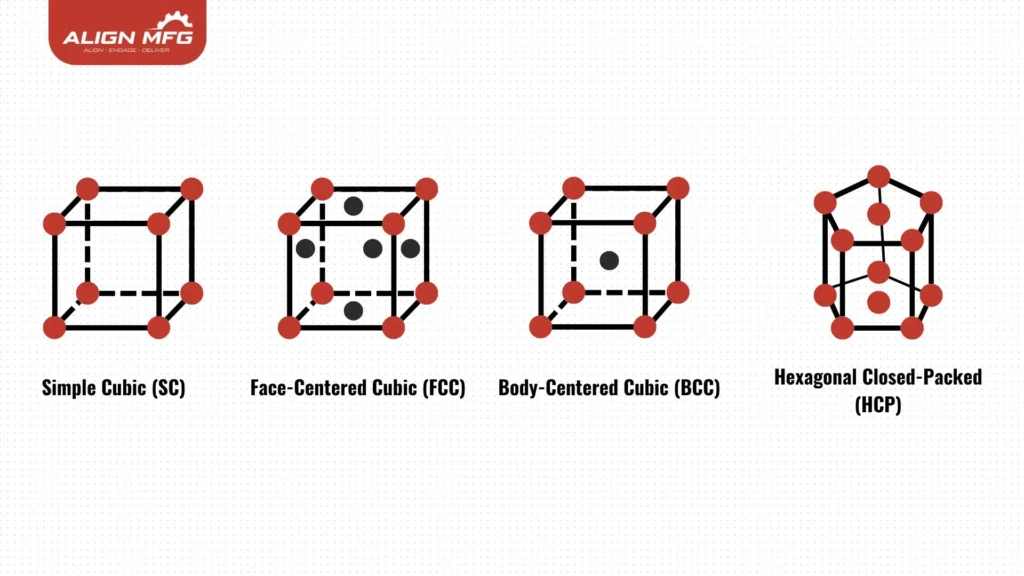

The foundation of stainless steel’s structure lies in the way iron atoms arrange themselves at different temperatures. Three primary phases characterize its transformation:

- Ferrite (α-iron): A body-centered cubic (BCC) structure dominant below 912°C, known for its magnetism and lower ductility.

- Austenite (γ-iron): A face-centered cubic (FCC) structure forming between 912°C and 1394°C, which enhances ductility and corrosion resistance.

- Delta Ferrite (δ-iron): A high-temperature BCC phase appearing above 1395°C before iron fully melts at 1538°C.

Influence of Alloying Elements

The addition of elements such as carbon, nickel, and manganese plays a crucial role in stabilizing these phases. Carbon increases hardness by promoting carbide formation, while nickel enhances the retention of the FCC structure at room temperature. This ability to maintain austenite at ambient conditions is critical for producing austenitic stainless steels, which are highly resistant to corrosion and non-magnetic.

The Role of Cooling and Heat Treatment

Steel’s final properties depend on how it cools post-processing:

- Slow Cooling (Annealing): Allows atoms to arrange into stable configurations, promoting ductility and toughness.

- Rapid Quenching: Traps the lattice in a strained configuration, leading to hard but brittle martensitic structures.

- Tempering: A controlled reheating process that refines martensitic steel, reducing brittleness while maintaining hardness.

Real-World Applications of Stainless Steel Microstructures

- Cryogenic Storage (Austenitic Steel – FCC): Retains strength and ductility even at extremely low temperatures, making it ideal for LNG storage tanks.

- High-Speed Machinery (Martensitic Steel – BCT): Hard, wear-resistant surfaces enable turbine blades and surgical tools to maintain sharpness.

- Bridges and Marine Environments (Duplex Steel – Mixed FCC & BCC): Provides a balance of corrosion resistance and structural strength.

- Magnetic Applications (Ferritic Steel – BCC): Used in motor components and electrical transformers where magnetism is required.

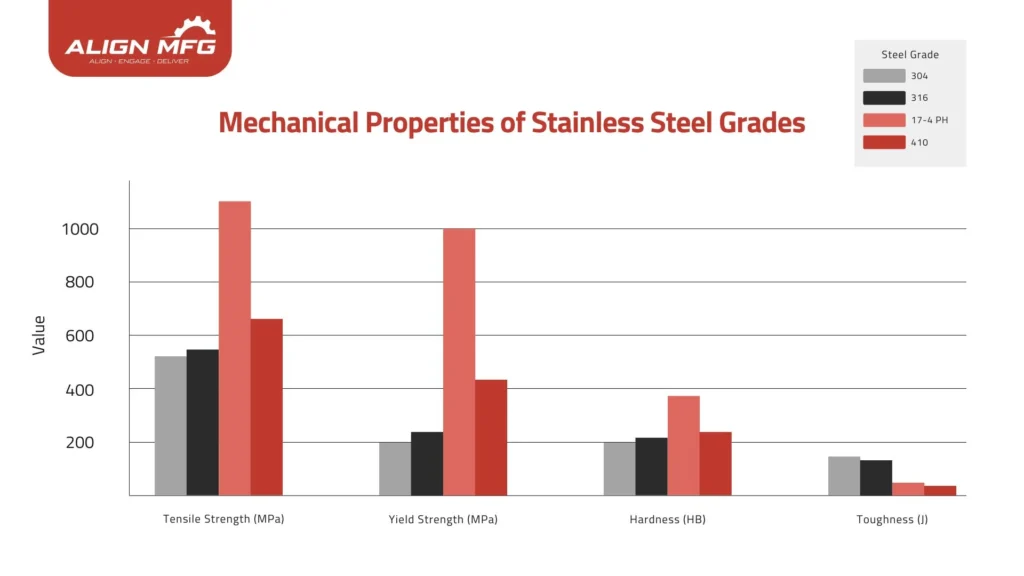

Other Key Factors in Selecting Stainless Steel Grades

When choosing the right stainless steel grade, consider:

- Corrosion Resistance – For marine or chemical environments, 316 or duplex stainless steel is recommended.

- Strength & Hardness – Applications requiring high strength should use martensitic or PH grades.

- Temperature Resistance – 321 and 430 are suitable for high-temperature environments.

- Cost Considerations – 201 or 430 are budget-friendly alternatives for non-critical applications.

- Magnetism – Austenitic stainless steels (300 series) are generally non-magnetic, whereas ferritic and martensitic steels (400 series) are magnetic.

Stainless steel grades vary significantly based on composition, mechanical properties, and applications. 304 and 316 are the most commonly used grades due to their excellent corrosion resistance, while martensitic and duplex grades are preferred for strength and durability.

Understanding the characteristics of each stainless steel grade is crucial for selecting the right material for a specific application. Whether you need stainless steel for kitchenware, medical devices, industrial machinery, or marine environments, choosing the right grade ensures optimal performance and longevity.

For more on stainless steel, request a custom quote or project with Align Manufacturing. We have served the metal manufacturing industry for over a decade and offer a comprehensive range of stainless steel products and services such as sand casting,

Extend the Life of Your Stainless Steel: A Maintenance Guide

How to Successfully Order Custom Castings: A Step-by-Step Guide

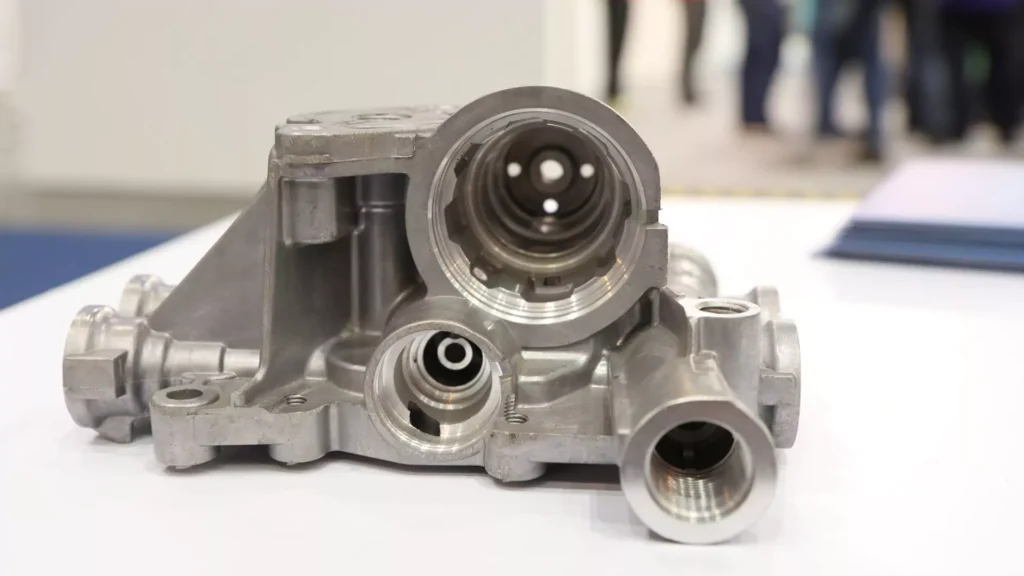

Metal casting has shaped human civilization since 4000 BC , evolving from ancient bronze statues to today's precision-engineered components. In the modern world, this transformative process—where molten metal is poured into carefully designed molds—drives a global industry worth over Us$179.08 billion.

Custom castings represent the cutting edge of this field, where advanced engineering meets ancient craft to create components that precisely match specific requirements.

The impact of custom castings touches virtually every aspect of modern life. From the engine blocks powering your car to the massive turbine housings generating electricity, from delicate medical devices to robust mining equipment, custom castings provide the backbone for countless industries. Their applications span an impressive range:

- Automotive components requiring exceptional durability

- Precision aerospace parts where failure isn't an option

- Heavy machinery for construction and farming

- Intricate architectural elements in landmark buildings

- Critical components in renewable energy systems

- Custom parts for shipbuilding and rail transportation

- Specialized equipment for oil and gas extraction

- Robust processing equipment for forestry and mining

While the possibilities are nearly limitless, achieving success in custom casting requires meticulous attention to detail and comprehensive planning. From initial design concepts to final production, each step demands careful consideration to ensure the finished product meets exact specifications while remaining cost-effective. This guide by Align Manufacturing will walk you through every crucial aspect of ordering custom castings, helping you navigate the complexities of this sophisticated manufacturing process.

1.Design Specifications

The first step in ordering custom castings is defining the design requirements. This includes:

Component Requirements

- The component's function

- Shape and dimensions

- Required mechanical properties

- Quantity needed

Critical Design Elements

- Minimum Section Thickness: Typically no thinner than 0.25 in (6 mm) for conventional processes

- Draft Requirements: Generally 3/16 in of draft per ft (approximately 1.5 degrees)

- Parting Line Considerations: Straight parting lines reduce costs and simplify production

- Core Design: Consider accessibility for core removal and minimum diameter requirements.

Mold Preparation: Crafting the Cavity

Core Design Considerations

The minimum diameter of a core depends on:

- The thickness of surrounding metal

- Core length

- Special foundry procedures

- Reinforcement needs for larger cores

- Accessibility for core removal

Collaborating with a casting manufacturer early ensures the design aligns with both functional requirements and manufacturability. Utilizing 3D modeling and simulations helps visualize the final product and identify potential design challenges.

2. Material Selection

Selecting the right material is crucial as it impacts performance, durability, and cost. Common casting materials include:

- Steel: High strength and wear resistance

- Aluminum: Lightweight with good corrosion resistance

- Brass/Bronze: Excellent for corrosion-resistant applications

- Specialized Alloys: Used for extreme environments

Material Selection Factors

- Required strength and hardness

- Corrosion and heat resistance

- Machinability and finishing needs

- Industry-specific regulations (e.g., ASTM, ISO)

4. Soundness & Quality Considerations

Understanding that perfect castings are impossible is crucial. Quality considerations include:

Defect Types

- Sand inclusions

- Slag inclusions

- Macroporosity

- Shrinkage

The Importance of Quality Control in Custom Casting Production

Establishing rigorous quality control (QC) measures is crucial to ensuring that custom castings meet performance requirements, comply with industry standards, and minimize costly defects. A well-defined QC process helps align manufacturing with customer expectations, ensuring consistent production and preventing disputes over acceptance criteria.

Key Quality Control Measures for Custom Castings

To maintain high standards, foundries and customers must establish clear acceptance and rejection criteria before production begins. Essential QC factors include:

✔ Acceptance & Rejection Criteria

- Clearly define the allowable defect levels and ensure both parties agree on what constitutes acceptable variations.

- Use recognized international standards (such as ASTM, ISO, or SAE) to benchmark quality expectations.

✔ Dimensional Tolerances & Surface Finish Requirements

- Specify critical tolerances to ensure precision and fit for the intended application.

- Define surface finish expectations based on the casting process used (e.g., investment casting vs. sand casting).

- Consider post-processing treatments (such as grinding, polishing, or machining) to achieve the required finish.

✔ Defining the Exact Alloy Specification

- Specify the exact metal alloy to be used, referencing an internationally recognized standard (ASTM, ISO, EN, or JIS).

- Different alloys offer varying levels of strength, corrosion resistance, and machinability.

- Ferrous Metals (Iron-Based): Cast steel (most common), stainless steel, ductile iron, malleable iron.

- Non-Ferrous Metals (Non-Iron-Based): Aluminum, copper, and specialty alloys.

✔ Soundness & Defect Control in Castings

- No casting is 100% free of defects, but strict control over metal purity, shrinkage, and porosity helps minimize imperfections.

- Implement Non-Destructive Testing (NDT) such as:

- Ultrasonic Testing (UT): Detects internal flaws.

- Radiographic Testing (X-ray): Examines internal structures for porosity and inclusions.

- Dye Penetrant Testing (DPT): Identifies cracks and surface defects.

- Foundries must follow ASTM acceptance criteria for evaluating defects and determining whether a casting meets specifications.

✔ Heat Treatment & Mechanical Properties

- Mechanical properties (strength, hardness, ductility, etc.) depend on solidification conditions, cooling rates, and heat treatment processes.

- Some alloys require post-casting heat treatment to achieve specific mechanical properties.

- Heat treatment options include:

- Normalizing & Annealing: Enhances ductility and removes internal stresses.

- Flame Hardening & Case Hardening: Improves surface hardness for wear resistance.

- Tempering & Quenching: Adjusts strength and toughness to required specifications.

Align Manufacturing ensures precise temperature control and monitoring using advanced heat treatment equipment to maintain consistent quality across production batches.

5. Prototyping

Before full-scale production, creating prototypes allows for functional testing through:

- 3D Printing

- Small-Batch Casting

- CNC Machining

6. Weight Considerations

Weight impacts both cost and production methods:

Weight Factors

- Net Weight: Final casting weight

- Gross Weight: Total metal poured, including gates and risers

- Casting Yield: Efficiency ratio between net and gross weight

- Material Cost Impact: Higher weight increases material costs

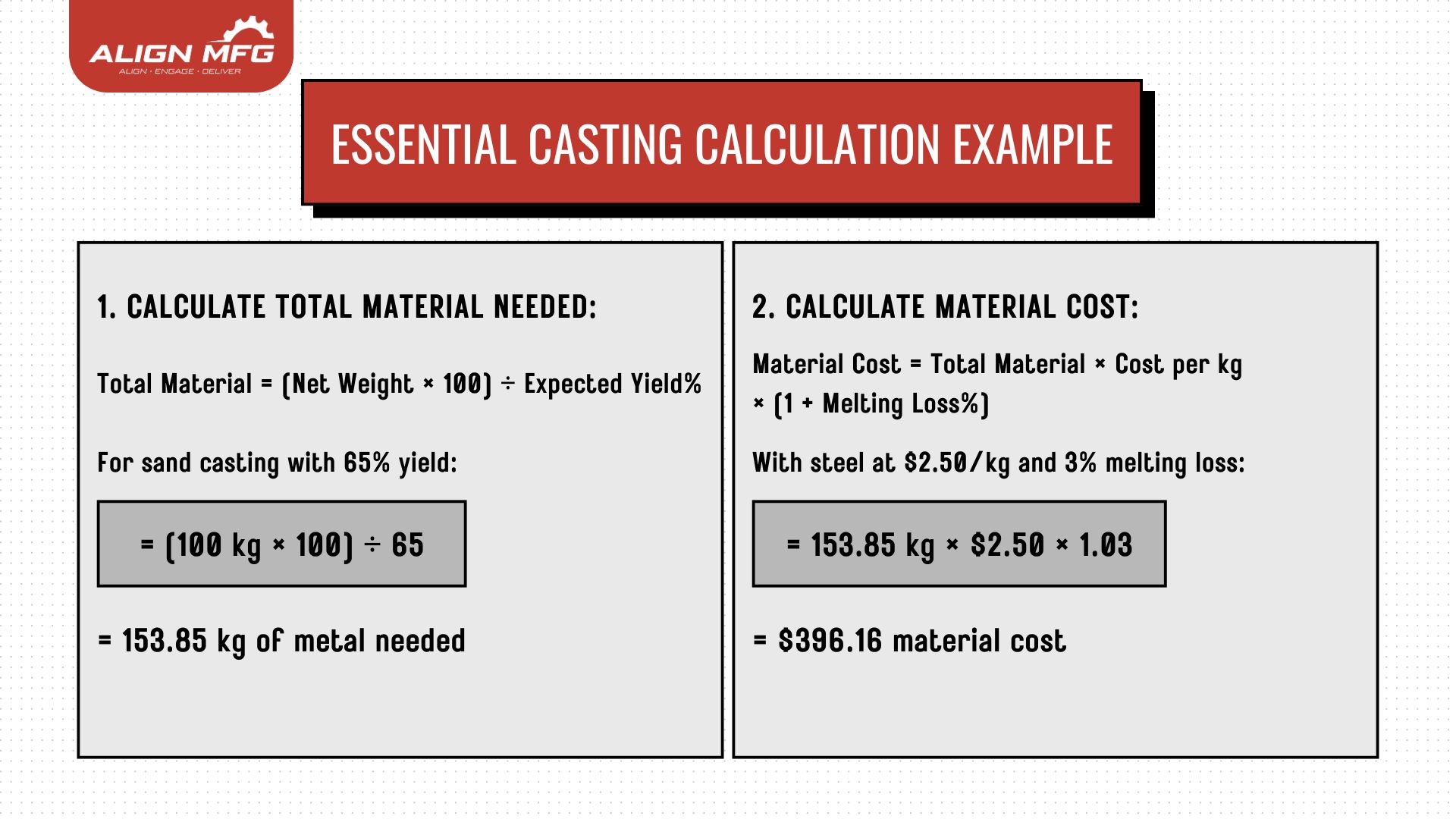

Let me streamline this into the most practical calculation that foundries commonly use.

Weight and Yield Calculations in Casting

The most critical calculation in casting is determining the total material needed and its cost, as this directly impacts project feasibility and pricing.

Key Weight Components

- Net Weight (Wn): Final casting weight

- Gross Weight (Wg): Total metal poured (including feeding system)

- Casting Yield: Efficiency ratio (typically 60-75% for sand casting)

Essential Casting Calculation Example

Let's say you need to produce a steel casting weighing 100 kg (net weight):

This basic calculation helps:

- Determine material requirements

- Estimate project costs

- Set appropriate pricing

- Plan production efficiency

Typical Yield Ranges (for reference):

- Sand Casting: 60-75%

- Die Casting: 85-95%

- Investment Casting: 55-65%

7. Pattern Equipment & Tooling

Pattern quality directly affects casting quality and costs:

Types of Patterns

Each pattern type offers distinct advantages and trade-offs:

- Wood Patterns

- Pros: Lower initial cost, easier to modify

- Cons: Shorter lifespan, can warp over time

- Best For: Low-volume production, prototyping, and sand casting

- Metal Patterns

- Pros: High durability, maintains precision over many cycles

- Cons: Higher upfront cost, heavier, harder to modify

- Best For: High-volume production, die casting, investment casting

- Mounted vs. Loose Patterns

- Mounted: Affixed to a plate for consistent alignment, improving repeatability

- Loose: Freely placed in the mold, more flexible but can lead to variations

- Split Patterns

- Used to simplify mold separation and improve accuracy in complex geometries

- Can involve full split core boxes or half core boxes, depending on foundry requirements

Pattern Considerations & Cost Implications

The decision on pattern design must take into account long-term costs, foundry compatibility, and quality control. Some key considerations include:

- Compatibility with Foundry Equipment

- Even if an existing pattern is available, a foundry may require new tooling to match its specific machinery.

- This can involve:

- Full split core boxes instead of half core boxes

- Metal pattern replacement for wooden patterns

- Switching to mounted patterns for better consistency

- Balancing Upfront Costs vs. Long-Term Savings

- More sophisticated pattern equipment leads to higher pattern costs initially.

- However, this investment reduces per-unit casting costs over time by:

- Increasing efficiency

- Improving dimensional accuracy

- Reducing scrap and rework

- Example: A metal pattern may cost 2-3x more than a wooden one, but for large-scale production, it can lower overall casting costs due to reduced wear and fewer defects.

- Storage & Maintenance

- Patterns require proper storage and maintenance to prolong their usability.

- Foundries may charge for pattern storage or request maintenance fees, especially for high-volume production.

- Investing in high-quality pattern materials reduces maintenance frequency and improves overall casting consistency.

The Design Phase: Pattern Creation

8. Testing & Inspection

Comprehensive testing ensures quality through:

Destructive Testing

- Requires separate test castings

- Provides internal soundness verification

- Used to validate production methods

Non-Destructive Testing (NDT)

- Visual Inspection

- Liquid Dye Penetrant Inspection (LPI)

- Magnetic Particle Inspection (MPI)

- Ultrasonic Testing (UT)

- Radiographic Inspection (X-Ray)

9. Machining Requirements

Machining considerations affect both design and cost:

Machining Factors

- Stock allowance for machined surfaces

- Fixture and clamping requirements

- Material specification impacts

- Production quantity considerations

Verification Process

- Complete layout for complex machining

- Target point marking

- First article inspection

- Machining allowance verification

10. Supplier Selection

Choose a reliable foundry based on:

- Experience & Expertise

- Certifications

- Production Capabilities

- Quality Control Measures

- Specialization (short-run vs. high-volume)

11. Requesting a Quote

Provide detailed information including:

- Technical Drawings

- Material Specifications

- Production Quantity

- Finishing Requirements

- Testing Requirements

- Delivery Timeline

12. Production & Delivery Timelines

Understanding typical timelines is crucial:

Timeline Components (up to 24 weeks)

- Commercial Administration

- Pattern/Tooling Construction

- Sampling

- Inspections

- Pattern Modifications

- Production Setup

- Manufacturing

- Post-Production Processing

Production Planning

- Early communication of delivery requirements

- Regular progress updates

- Buffer time for unexpected issues

- Quality control checkpoints

Final Thoughts

Success in custom casting projects requires:

- Thorough planning and design

- Clear communication with suppliers

- Understanding of manufacturing constraints

- Comprehensive quality control

- Realistic timeline expectations

By considering all these factors during the planning and ordering process, you can achieve cost-effective and high-performance custom castings suited to your needs.

Frequently Asked Questions (FAQs)

For more information or to discuss your specific project needs, contact us today.

How to Weld Cast Iron Without Cracking: Best Methods, Tips, and Techniques

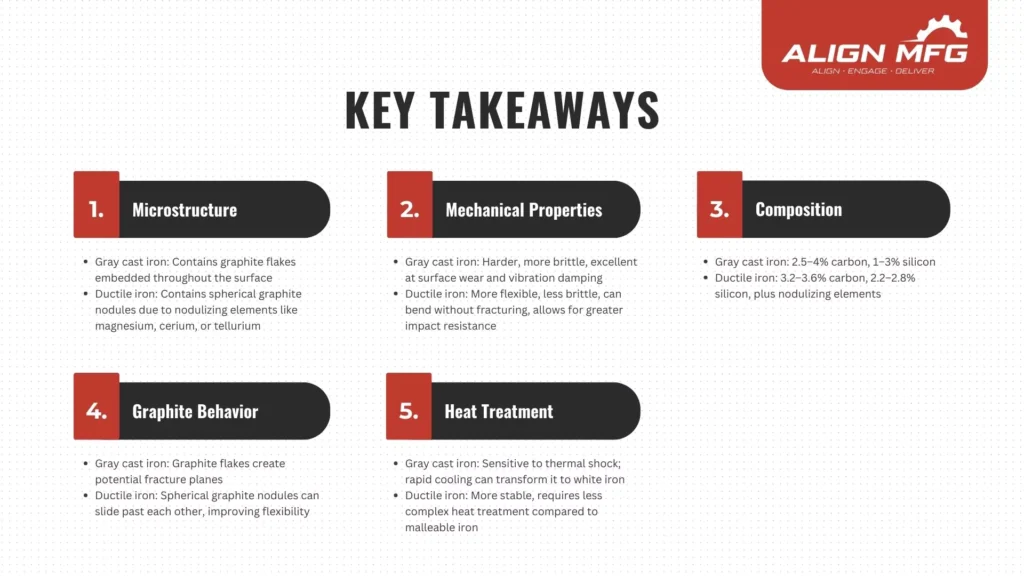

Welding cast iron is a specialized process that requires careful attention due to its unique properties. This elevated carbon level makes cast iron prone to cracking and other challenges during welding. In this article, we will explore the definition of cast iron, the challenges associated with welding it, effective techniques, and best practices to ensure successful outcomes.

What Is Cast Iron?

Cast iron is an iron-carbon alloy characterized by its high carbon content, typically between 2% and 4%. This composition gives cast iron its distinctive hardness and brittleness. Common types of cast iron include gray cast iron, white cast iron, ductile (nodular) cast iron, and malleable cast iron, each with varying properties and applications.

- Gray Cast Iron: Gray cast iron is the most common type of cast iron, characterized by graphite flakes that form within a pearlite or ferrite microstructure. While it is more ductile and weldable than white cast iron, these graphite flakes can enter the weld pool, leading to embrittlement and weakened welds. To achieve a successful weld, preheating and careful filler metal selection are crucial to minimizing cracking and maintaining structural integrity. Due to these challenges, welding gray cast iron requires expertise and a controlled approach to ensure durable and machinable results.

- White Cast Iron: White cast iron is known for its extreme hardness and brittleness, as it retains carbon in the form of iron carbide (cementite) rather than graphite. This cementite microstructure makes the material highly wear-resistant but also incredibly difficult to machine or weld. Unlike gray cast iron, which allows some degree of weldability, white cast iron is unweldable due to its tendency to crack under thermal stress.

- Attempts to weld white cast iron often result in rapid cooling and the formation of even harder, brittle microstructures, making post-weld machining nearly impossible. In cases where repair is necessary, alternatives such as brazing or buttering with a machinable weld overlay are sometimes used. Another approach is to anneal white cast iron before welding, converting some of the iron carbide into graphite to improve ductility—though this is rarely practical in most industrial applications. Given these challenges, white cast iron is typically repaired using mechanical fastening methods or part replacement rather than welding.

- Ductile (Nodular) Cast Iron: More flexible and weldable than gray cast iron, but still requires special techniques.

- Malleable Cast Iron: Similar to ductile cast iron, it has some flexibility but is more challenging to weld without preheating.

Identifying the cast iron type helps determine the right welding approach and filler material.

Challenges in Welding Cast Iron

Welding cast iron presents several challenges, primarily due to its high carbon content and brittle nature. Key issues include:

- Cracking: Rapid cooling can lead to the formation of hard, brittle microstructures, increasing the risk of cracks.

- Porosity: Entrapped gases during welding can cause porosity, weakening the weld.

- Contamination: Surface impurities like oil, grease, and rust can lead to defects in the weld.

- Hardening: The heat-affected zone (HAZ) can become excessively hard, making machining difficult.

Techniques for Welding Cast Iron

Several welding methods are suitable for cast iron, each with its advantages and considerations:

1. Shielded Metal Arc Welding (SMAW)

Also known as stick welding, Shielded Metal Arc Welding (SMAW) is one of the most commonly used techniques for welding cast iron. The process utilizes a consumable electrode coated with flux, which creates a protective gas shield when burned, preventing contamination and ensuring a clean weld.

Different types of electrodes can be used depending on the application, required color match, and post-weld machinability. The three primary filler materials for cast iron stick welding include:

- Cast iron covered electrodes – Designed for cast iron applications, though they may be brittle.

- Copper alloy electrodes – Provide a strong bond but are less common for structural welding.

- Nickel alloy electrodes – The most popular choice due to their compatibility with cast iron’s properties.

Nickel-based electrodes are especially preferred because they create a softer, more ductile weld that is less prone to cracking. According to New Hampshire Materials Laboratory Inc., nickel-iron welds are stronger and have a lower coefficient of thermal expansion, reducing welding stresses and improving crack resistance.

Key Considerations for SMAW on Cast Iron:

- Electrode Handling: An electric arc between the electrode and the welding area melts the metals and enables fusion. The arc should be directed at the weld pool, not the base metal, to minimize dilution and reduce hardening.

- Current Setting: It is recommended to use the lowest current setting approved by the manufacturer to avoid excessive heat input, which can increase the likelihood of cracking.

- Preheating: Heating the workpiece to a moderate temperature (typically between 500°F and 1200°F) helps to reduce thermal stress and minimize the formation of brittle zones.

- Post-Weld Cooling: Gradual cooling is essential to prevent cracking. Wrapping the part in an insulating blanket or burying it in dry sand helps slow the cooling rate and prevents the formation of hard, brittle microstructures.

2. Oxy-Acetylene Welding

This method uses a flame produced by burning acetylene with oxygen to weld cast iron. It allows for slow heating and cooling, which can reduce the risk of cracking. A cast iron filler rod is typically used, and the process is suitable for repairing thin sections or intricate parts. However, it requires skilled handling to avoid overheating and potential distortion.

3. Braze Welding

Braze welding involves using a filler metal with a lower melting point than the base metal, such as a bronze or brass alloy. This filler metal melts and flows into the joint through capillary action.This technique is beneficial for joining dissimilar metals and minimizing heat-induced stresses, as it does not melt the base cast iron. Proper surface preparation and flux application are essential to ensure a strong, defect-free joint.

Best Practices for Welding Cast Iron

To achieve optimal results when welding cast iron, consider the following best practices:

Best Practices for Welding Cast Iron

1. Surface Preparation

Proper surface preparation ensures a clean and strong weld.

- Thorough Cleaning: Remove paint, rust, oil, and grease before welding to prevent impurities in the weld pool.

- Avoid Abrasive Grinding: Using abrasive tools can smear graphite over the surface, leading to porosity. Instead, use a carbide burr or gouging electrode for preparation.

2. Preheating the Cast Iron

Preheating Cast Iron: Why It Matters and How to Do It Right

Preheating cast iron is a critical step in preventing thermal stress, cracking, and weld failure. Since cast iron is brittle and has poor ductility, it does not stretch to relieve stress like steel or other ductile metals. Instead, any localized heating can result in restricted expansion, leading to stress buildup and ultimately cracking during the cooling phase.

Why Preheating is Important

The primary reason for preheating is to control thermal expansion and contraction during welding. If only the weld zone heats up, while the surrounding metal remains cool, the heat-affected zone (HAZ) expands unevenly, creating internal tensile stresses that can cause cracks—either immediately or after cooling.

Preheating reduces the thermal gradient between the weld area and the rest of the casting, allowing for a more uniform expansion and contraction. This minimizes stress buildup and lowers the risk of cracking both during and after welding.

How to Properly Preheat Cast Iron

1. Determining the Right Preheat Temperature

The required preheat temperature depends on:

- Type of Cast Iron:

- Gray cast iron: 500°F - 1200°F (260°C - 650°C)

- Ductile cast iron: 500°F - 900°F (260°C - 480°C)

- White cast iron: Typically unweldable; extreme caution required

- Size and Thickness of the Casting:

- Thicker and larger castings require higher preheating temperatures to ensure even heat distribution.

- Welding Method Used:

- Higher-temperature welding methods (e.g., stick welding) require higher preheating temperatures.

- Lower-temperature methods (e.g., brazing) may require little or no preheating.

2. Even Heating: Preventing Uneven Expansion

- Heat the entire casting evenly to avoid creating temperature differentials that can induce stress.

- Use large ovens, torches, or induction heating to distribute heat uniformly.

- Avoid spot heating, as this can cause localized expansion, leading to cracks.

- Slow heating is crucial—do not rush the preheating process.

3. Maintaining a Consistent Temperature

- Once the desired temperature is reached, maintain it throughout the welding process.

- If the workpiece cools below the necessary preheat temperature during welding, reheat it before proceeding.

- Use temperature indicating sticks, thermocouples, or infrared thermometers to monitor temperature.

What to Do When Preheating Isn’t Possible

In some cases, preheating may not be practical due to part size, accessibility, or equipment limitations.

Use a low-heat welding process (such as TIG or brazing).

- Select low-melting-point welding rods or wires to reduce heat input.

- Increase interpass cooling time—welding in small passes with extended cooling time between them.

- Apply peening between weld passes to relieve stress.

3. Welding Techniques

Different welding techniques can be used for cast iron, each with advantages and considerations.

Shielded Metal Arc Welding (SMAW) - Stick Welding

- Uses nickel-based or cast iron-specific electrodes.

- Requires preheating for best results.

- Produces a strong, machinable weld.

Oxy-Acetylene Welding

- Allows for slow heating and cooling.

- Suitable for thin sections and small repairs.

- Requires a cast iron filler rod.

Braze Welding

- Uses a filler metal with a lower melting point.

- Ideal for joining dissimilar metals.

- Reduces heat-induced stress.

In-House Welding Feasibility

While welding cast iron in-house is possible, for critical repairs or structural components, professional expertise is recommended to ensure weld integrity.

4. Welding Execution Techniques

Certain techniques can improve the chances of a successful weld.

- Short Weld Passes: Limit weld beads to 1 inch (25 mm) or less to control heat input and minimize cracking (WeldingHandbook.com).

- Peening: Gently hammering the weld bead while still hot relieves internal stress and prevents cracking (WeldingHandbook.com).

5. Filler Material Selection

Choosing the right filler material is crucial to a strong and durable weld.

- Nickel-Based Electrodes:

- 99% Nickel rods are preferred for their machinability and compatibility with cast iron.

- Ferro-nickel rods (47% nickel, 53% steel) are more affordable and suitable for welding cast iron to steel.

6. Cooling Methods

Controlled cooling is essential to avoid cracks and maintain weld integrity.

- Slow Cooling: Rapid cooling can lead to hardening and cracking. Wrap the welded part in an insulating blanket or bury it in dry sand to cool gradually (MakeItFromMetal.com).

- Slow cooling methods include:

- Wrapping the welded part in heat-resistant blankets

- Burying the casting in dry sand, ashes, or lime

- Placing it in an insulated oven for controlled cooling

- Never quench or expose the welded part to sudden temperature drops, as this will create excessive stress and lead to cracking.

By understanding the inherent challenges of welding cast iron and implementing these techniques and best practices, welders can achieve strong, durable repairs and fabrications.

7. Alternative Methods for Repairing Cast Iron

In some cases, welding may not be the best option. Alternative techniques include:

- Brazing: Uses a filler metal that melts at a lower temperature than the base metal, reducing thermal stress.

- Suitable for non-structural repairs or when welding risks damaging the part.

(Eng-Tips.com).

- Suitable for non-structural repairs or when welding risks damaging the part.

Welding plays a crucial role in the broader manufacturing ecosystem, often complementing our key processes such as casting, forging, and machining. By understanding how welding fits into fabrication and assembly workflows, manufacturers can make more informed decisions about when to incorporate welding into their production strategies.

Whether you need high-strength cast components, machined parts with tight tolerances, or fabricated assemblies, Align helps you achieve cost-effective and durable manufacturing solutions tailored to your industry needs.

Frequently Asked Questions (FAQs)

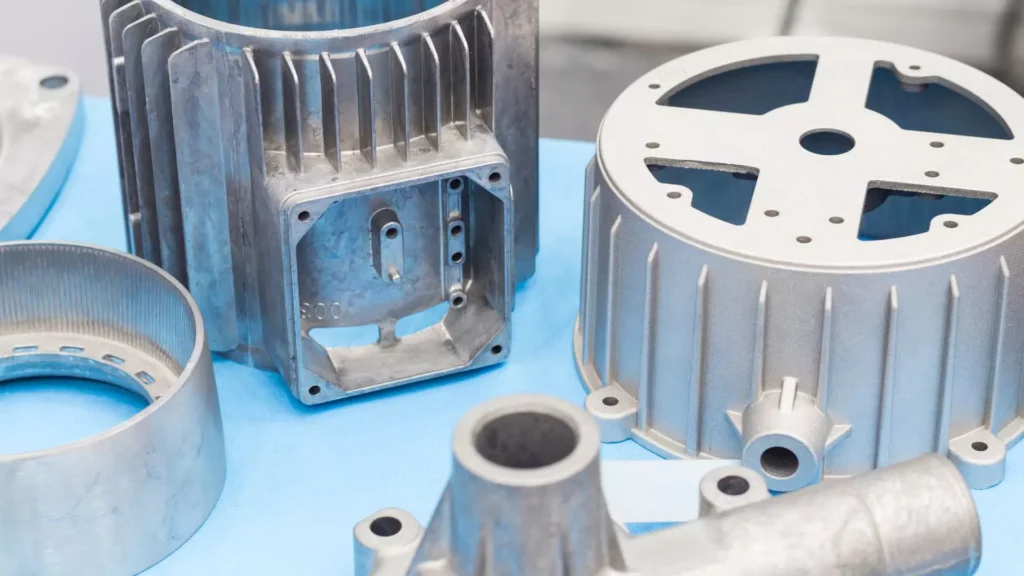

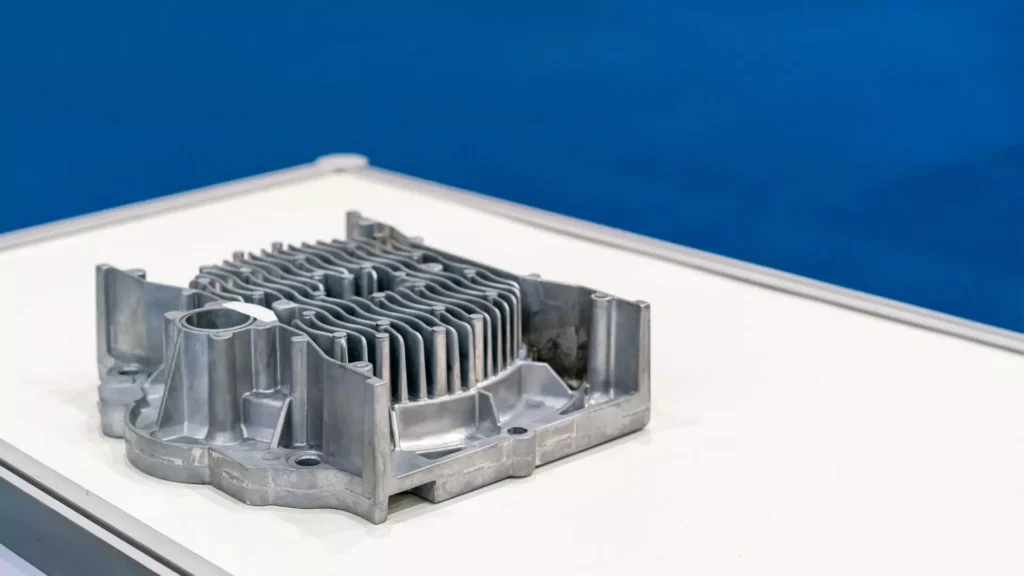

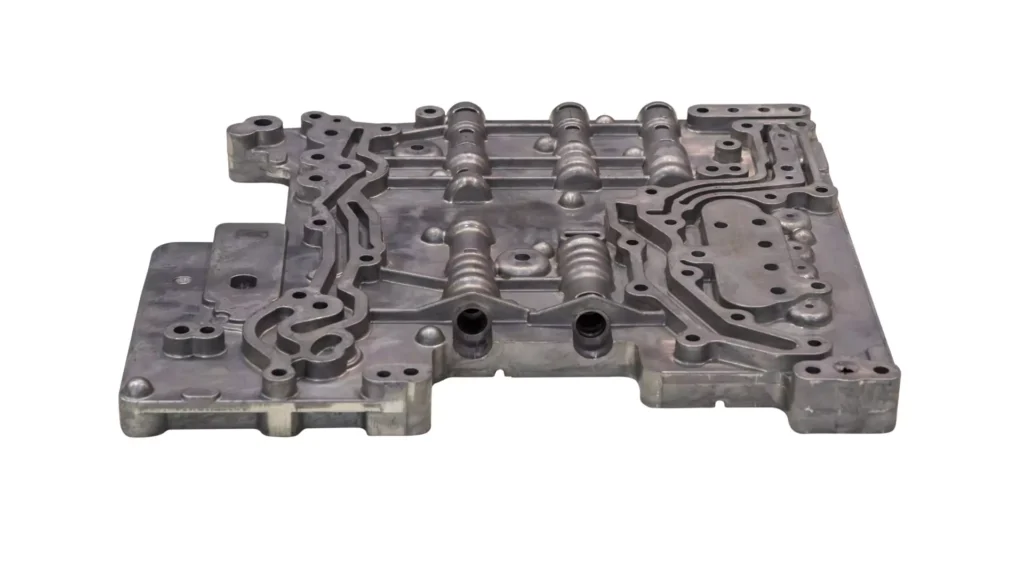

Cast Aluminum: Benefits, Applications, and Manufacturing Process

Cast aluminum is more than just a material; it’s a versatile cornerstone in the manufacturing world, enabling the creation of products that shape our everyday life. From the car you drive to the pots and pans in your kitchen, cast aluminum plays a pivotal role. This blog post will guide you through the essence of cast aluminum, its unique properties, the advantages and challenges it presents, and how it stacks up against other metals like cast steel and grey iron.

What is Cast Aluminum?

Cast aluminum refers to a process where aluminum is melted and poured into a mold to create complex shapes and components. Unlike wrought aluminum, which is shaped through methods like rolling, hammering, or extruding, casting allows for intricate designs and detailed textures that would be difficult or impossible to achieve with other techniques. This versatility makes cast aluminum an attractive option for manufacturers seeking to produce high-quality parts with precision.

The Aluminum Casting Process

The journey of creating a cast aluminum part involves several steps. It begins with melting aluminum ingots or scraps and then injecting the molten metal into a steel or aluminum mold under high pressure. Once the aluminum cools and solidifies, the mold opens to reveal a lightweight yet sturdy component. Techniques like die casting, permanent mold casting, and sand casting are commonly employed, each suitable for different complexity levels and production volumes.

| Process | Description | Key Features | Applications |

| Die Casting | High-pressure injection of molten aluminum into a metal mold. | Fast, precise, excellent surface finish, high dimensional accuracy, and good thermal conductivity. | Automotive, electronics, consumer goods. |

| Sand Casting | Molten aluminum is poured into a mold made from a sand mixture. | Low tooling cost, suitable for large and complex parts, flexible in size and shape, but rougher surface finish. | Heavy machinery, industrial equipment. |

| Permanent Mold Casting | Molten aluminum is poured into reusable metal molds using gravity or low pressure. | Consistent quality, smoother finish than sand casting, good dimensional stability, and improved mechanical properties. | Automotive, aerospace components. |

The Properties of Cast Aluminum

Aluminum casting alloys typically contain over 90% aluminum, with other elements like silicon, copper, magnesium, or zinc added to enhance specific characteristics. Here are some key properties that make cast aluminum a popular choice:

- Lightweight: Aluminum’s low density makes it an ideal choice for applications where weight reduction is crucial without sacrificing strength. This property is particularly valuable in industries like automotive and aerospace, where every ounce counts.

- Strength and Durability: While not as strong as steel, certain cast aluminum alloys offer impressive strength and durability, often exceeding that of plastic or wood. This makes it suitable for a range of demanding applications.

- Corrosion Resistance: Aluminum naturally forms a protective oxide coating when exposed to air, rendering it resistant to corrosion. This characteristic can be further enhanced through treatments like anodizing or painting, making it ideal for outdoor applications.

- Conductivity: Aluminum is an excellent conductor of heat and electricity, which makes it suitable for applications like heat sinks in electronics and electrical components.

- Recyclability: Aluminum is 100% recyclable without any loss of quality, contributing to its popularity in sustainable manufacturing practices. This aspect aligns with the growing emphasis on eco-friendly production methods.

Benefits of Using Cast Aluminum

The advantages of using cast aluminum in manufacturing are vast:

- Design Flexibility: The casting process allows for the creation of complex shapes and intricate details, providing designers with a high degree of creative freedom. This flexibility enables the production of parts that are both functional and aesthetically pleasing.

- Cost-Effective Production: Aluminum casting can be more cost-effective than other metalworking processes, especially for large production runs. The ability to produce multiple parts in a single cycle reduces overall costs.

- Reduced Assembly Needs: Components can often be designed to consolidate multiple parts into a single cast, minimizing the need for assembly and lowering production costs.

- Superior Aesthetics: Cast aluminum can achieve a high-quality surface finish that is both functional and visually appealing, making it suitable for consumer products where appearance matters.

Applications of Cast Aluminum

The versatility of cast aluminum makes it a staple in numerous industries:

- Automotive: Engine components, wheels, and transmission housings are often made from cast aluminum for their strength and lightweight properties.

- Aerospace: The process is used to create structural parts for aircraft that require precision and strength without adding unnecessary weight.

- Consumer Goods: Everything from electronics to cookware benefits from aluminum’s thermal properties and ease of casting.

- Construction: Aluminum casting is used in building materials for its durability and resistance to corrosion.

Disadvantages of Cast Aluminum

While cast aluminum offers numerous benefits, there are some limitations to consider:

- Lower Strength Compared to Steel: Although strong, cast aluminum does not match the tensile strength of steel, which can limit its use in high-stress applications.

- Brittleness: Certain aluminum alloys can be more brittle than other metals, especially under extreme conditions, leading to potential cracking.

- Higher Initial Costs: The costs associated with casting aluminum can be higher than some other materials, particularly if complex molds are required.

Cast Aluminum vs. Cast Steel

When comparing cast aluminum to cast steel, several factors come into play:

Strength and Weight

Cast steel generally offers higher strength, but cast aluminum’s strength-to-weight ratio is advantageous for many applications.

Cost Implications

Cast steel can be more expensive due to its material properties and the energy required to produce it.

Application Suitability

- Cast Steel: Preferred for heavy-duty structural components due to its high strength.

- Cast Aluminum: Chosen for applications where weight savings are critical, such as in transportation and mobile equipment.

Cast Aluminum vs. Grey Iron

Grey iron and cast aluminum are used in different scenarios based on their material characteristics:

Material Characteristics

Grey iron is known for its compressive strength and excellent vibration damping, whereas cast aluminum offers better corrosion resistance and weight savings.

Machinability and Usage

Grey iron is easily machinable but cast aluminum is preferred for complex shapes and thin-walled components.

Industry Preferences

- Grey Iron: Favored in the construction and industrial sectors.

- Cast Aluminum: Popular in the automotive, aerospace, and consumer electronics industries due to its lightness and durability.

Comparison of Cast Aluminum, Cast Steel, and Grey Iron

| Property/Aspect | Cast Aluminum | Cast Steel | Grey Iron |

| Density | ~2.7 g/cm³, lightweight. | ~7.7–7.85 g/cm³, heavier. | ~7.1–7.3 g/cm³, relatively heavy. |

| Tensile Strength | 100–400 MPa; 7068 alloy can reach 710 MPa. | 340–1800 MPa, depending on alloy and heat treatment. | 150–400 MPa; ASTM A48 Class 40 has 276 MPa. |

| Compressive Strength | Good, lower than cast iron; depends on alloy. | High, suitable for heavy loads. | Excellent, often >1000 MPa. |

| Melting Point | 570–655°C. | 1450–1520°C. | 1150–1250°C. |

| Thermal Conductivity | 120–180 W/m·K, excellent for heat dissipation. | Moderate. | ~46 W/m·K, moderate. |

| Electrical Conductivity | Good, ideal for electrical components. | Poor, not suited for electrical applications. | Poor, unsuitable for electrical applications. |

| Machinability | Easy to machine, allows for complex shapes. | Moderate, requires specialized tools. | Good machinability; brittleness requires care. |

| Corrosion Resistance | Excellent; protective oxide layer enhances durability. | Moderate; rusts without surface treatment. | Poor; prone to corrosion, especially in moisture. |

| Vibration Damping | Moderate; less effective than grey iron. | Good; better than aluminum but less effective than grey iron. | Excellent; graphite flakes provide superior damping. |

| Common Applications | Automotive parts, aerospace components, consumer electronics. | Heavy machinery, structural components, applications needing high strength and toughness. | Engine blocks, machine bases, pipes, and vibration-damping applications. |

| Cost | Lower for mass production due to efficiency and material availability. | Higher, due to material and processing costs. | Moderate; brittleness may lead to higher maintenance or replacement costs in specific applications. |

Conclusion

Cast aluminum stands as a testament to the ingenuity of modern manufacturing. With its blend of durability, versatility, and sustainability, this material continues to push the boundaries of what’s possible across various sectors. Whether it’s in the engine of your car, the body of your smartphone, or the frame of your bicycle, cast aluminum is a material that not only meets the demands of today’s manufacturers but also holds promise for the innovations of tomorrow.

For businesses looking to maximize the benefits of cast aluminum in their products, Align Manufacturing offers expert engineering solutions and support to help navigate the complexities of aluminum casting. Their commitment to quality and efficiency ensures that your projects meet the highest standards and expectations.

FAQs

Aluminum Die Casting: Definition & Process

Key Takeaways: Aluminum Die Casting

| Aspect | Key Details |

| What It Is | A manufacturing process that produces smooth, textured, and precise metal parts. |

| How It Works | Involves forcing molten aluminum into a steel mold (die) using high-pressure systems. |

| Key Properties | - Corrosion resistance- High thermal and electrical conductivity- Good stiffness and strength-to-weight ratio. |

| Advantages | - Lightweight and high dimensional stability- Suitable for complex geometries and thin walls- Cost-effective compared to other casting processes. |

| Production Efficiency | - Rapid production allows high volumes to be produced quickly.- Ideal for mass manufacturing. |

| Durability | Retains strength and dimensional stability even at very high temperatures. |

| Cold Chamber Process | Uses cold chamber machines to handle molten aluminum, which is ladled into the die due to high operating temperatures. |

| Applications | Widely used in automotive, aerospace, electronics, and consumer goods for durable, lightweight parts. |

Aluminum die casting has become a transformative force in the manufacturing industry, offering unparalleled efficiency, precision, and durability for a wide range of products. This process is a staple in sectors such as automotive, aerospace, electronics, and consumer goods due to its ability to produce complex shapes with high accuracy. In this comprehensive guide, we will explore the intricacies of aluminum die casting, including its various applications, types, advantages, disadvantages, and the overall process involved.

What is Aluminum Die Casting?

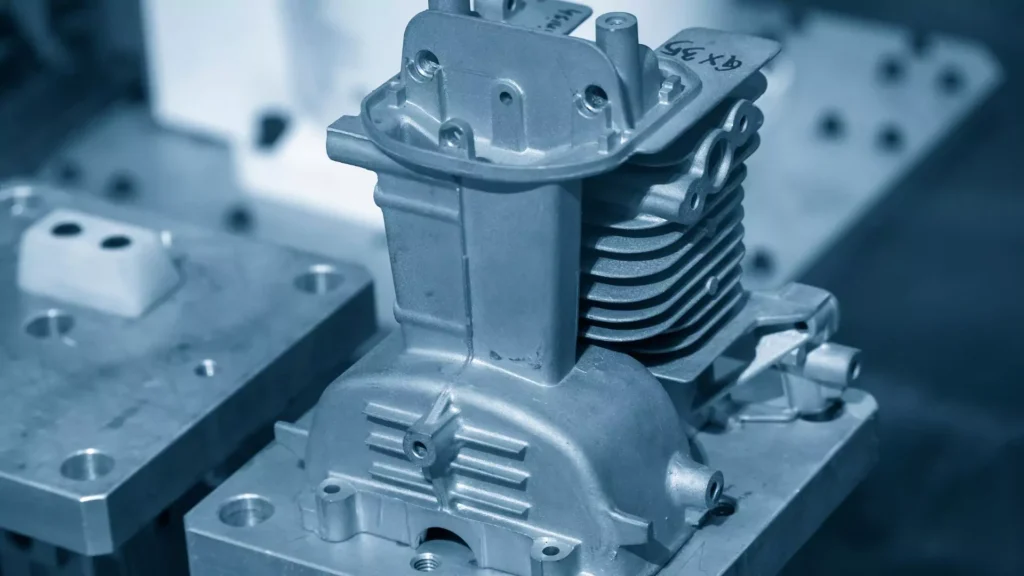

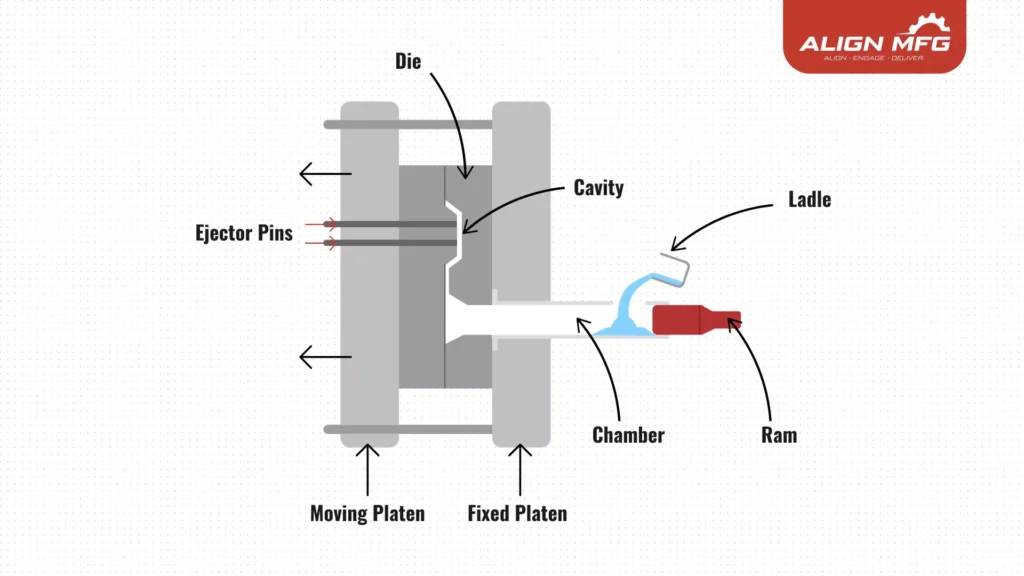

Aluminum die casting is a metal fabrication process that involves forcing molten aluminum under high pressure into a steel mold, known as a die. Once the aluminum solidifies, the die is opened to reveal a lightweight yet sturdy component. This method allows for the creation of intricate designs and tight tolerances, making it ideal for mass production of detailed parts.

The Aluminum Die Casting Process

The aluminum die casting process typically follows these key steps:

The Aluminum Die Casting Process

The aluminum die casting process follows these key steps, each involving precise engineering to ensure high-quality results:

- Mold Design and Creation:

- The process begins with designing and manufacturing a durable steel mold capable of producing tens of thousands of castings.

- Each mold consists of at least two sections, allowing for the removal of cast parts. Depending on the complexity of the design, molds may include movable slides, cores, or other specialized sections.

- Clamping and Preparation:

- The two mold halves are mounted securely in the die casting machine. One half remains stationary, while the other is movable.

- Before injection, the mold halves are clamped tightly together using hydraulic cylinders or direct hydraulic pressure, ensuring no gaps exist for molten aluminum to escape.

- Melting and Injection:

- Aluminum is melted in a furnace to the necessary temperature and prepared for injection.

- The molten aluminum is then injected into the die cavity under high pressure, which ensures the material fills every detail of the mold.

- Depending on the machine type (cold chamber or hot chamber), the method of injecting molten aluminum may vary, but the fundamental principles remain the same.

- Hot chamber machines feature a built-in furnace that melts the metal directly within the casting machine, making it ideal for low-melting-point metals like zinc and magnesium alloys. This process is faster, with shorter cycle times.

- Cold chamber machines, on the other hand, use an external furnace to melt higher-melting-point metals, such as aluminum and brass. The molten metal is then transferred to the casting machine using a ladle, resulting in longer cycle times due to the additional transfer step.

- Cooling and Solidification:

- The molten aluminum rapidly cools within the mold cavity, taking on its precise shape as it solidifies.

- The rapid cooling process enhances the part’s dimensional accuracy and structural integrity.

- Ejection:

- Once the part has solidified, the movable die half separates from the stationary half.

- The casting is ejected using ejector pins or other mechanisms, ensuring smooth removal without damaging the mold or the part.

- Trimming and Flash Removal:

- Excess material, known as flash, is trimmed away to refine the part's edges and ensure it meets design specifications.

- Additional trimming may be needed for complex designs with slides or cores.

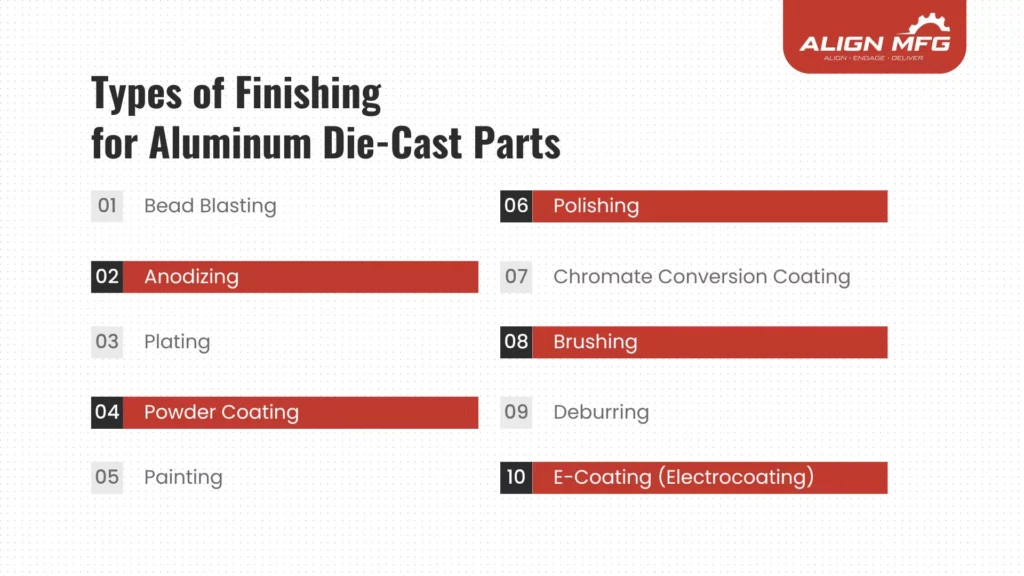

- Finishing:

Types of Finishing for Aluminum Die-Cast Parts

Bead Blasting

- Creates a uniform, matte finish by using fine beads to smooth and clean the surface.

- Ideal for aesthetic purposes and removing minor surface imperfections.

Anodizing

- Enhances corrosion resistance, improves wear resistance, and provides a decorative finish.

- Available in various colors and commonly used in consumer goods and automotive applications.

Plating

- Adds a protective or decorative metal layer (e.g., chrome, nickel) to improve durability and aesthetics.

- Often used in electrical, automotive, and decorative parts.

Powder Coating

- Provides a durable, corrosion-resistant, and attractive finish using an electrostatically applied powder that is baked to cure.

- Available in a wide range of colors and textures, commonly used in industrial and outdoor applications.

Painting

- Used for aesthetic purposes or additional corrosion resistance.

- Includes wet painting or spray painting with various finishes (glossy, matte, etc.).

Polishing

- Achieves a smooth, reflective surface by mechanically buffing the part.

- Often applied to components requiring a sleek, high-end look.

Chromate Conversion Coating

- A chemical treatment to improve corrosion resistance and paint adhesion.

- Commonly used in aerospace and automotive parts.

Brushing

- Produces a directional, textured finish with fine lines, enhancing visual appeal while reducing visible imperfections.

Deburring

- Removes sharp edges or burrs left from the die-casting process to improve safety and functionality.

E-Coating (Electrocoating)

- Involves immersing the part in a liquid paint solution and applying an electric charge to coat the surface uniformly.

- Offers excellent corrosion resistance and is used in automotive and industrial applications.

These finishing options enhance the appearance, durability, and performance of aluminum die-cast parts, making them suitable for diverse applications across industries.

Different Types of Aluminum Casting

Aluminum casting can be categorized into several types, each suited for specific applications:

- Die Casting: As discussed, this involves forcing molten aluminum into a mold under high pressure. It's ideal for high-volume production of complex parts.

- Sand Casting: This method uses sand molds to create parts by pouring molten aluminum into the mold. It's more flexible for low-volume production and complex shapes but may not provide the same precision as die casting.

- Investment Casting: Also known as lost-wax casting, this technique involves creating a wax model, coating it in ceramic, and then melting away the wax to leave a mold for aluminum. It’s excellent for intricate designs but is generally more expensive.

Advantages of Aluminum Die Casting

The benefits of using aluminum die casting in manufacturing are numerous:

- High-Speed Production: Die casting enables rapid production of parts, significantly reducing lead times and allowing for high-volume manufacturing without sacrificing quality.

- Dimensional Accuracy and Stability: The die casting process produces parts with exceptional precision and consistency, ensuring that each piece meets strict specifications.

- Strength and Lightweight: Aluminum’s natural strength-to-weight ratio makes it perfect for creating robust parts that are lighter than those made from other metals, contributing to fuel efficiency in automotive and aerospace applications.

- Multiple Finishing Techniques: Aluminum die cast parts can be easily finished with various techniques, including sandblasting, painting, or plating, providing aesthetic versatility and additional corrosion resistance.

- Recyclability: Aluminum is highly recyclable, which reduces waste and promotes sustainability in manufacturing.

Disadvantages of Aluminum Die Casting

While aluminum die casting has many advantages, there are also some limitations to consider:

- High Startup Costs: High Startup Costs: The initial tooling costs for die casting can be significant, as custom molds need to be designed and manufactured, which can be time-consuming and expensive. Additionally, CNC machines are often required for precision machining and finishing of the die-cast parts, further increasing the upfront investment.

For more on how to reduce costs when buying aluminum die cast parts,check out our guide.

- Limited to High-Volume Production: Due to the high costs associated with tooling, die casting is most economical for medium to high-volume production runs. Smaller production runs can lead to increased per-unit costs.

- Complex Geometries Can Be Costly: Parts with intricate designs may require additional machining or sliding cores, increasing the overall production cost.

- Low Initial Production Speed: The tooling process can take time before any final production parts are made, which can delay the start of manufacturing.

Grades of Aluminum Die Casting

Aluminum die casting utilizes various grades of aluminum alloys, each offering different properties:

- A380: This is the most commonly used grade due to its excellent casting characteristics, mechanical strength, and thermal properties. It offers good castability and is cost-effective.

- A383 / ADC12: This grade is great for intricate parts with thin walls and has better corrosion resistance than A380, although it has lower tensile strength.

- A413: Known for its excellent pressure tightness, this grade is ideal for high-pressure applications and offers superior corrosion resistance.

Applications of Aluminum Die Casting

The versatility of aluminum die casting leads to its use in various industries:

- Automotive: Parts such as engine components, transmission cases, and structural components benefit from aluminum's lightweight and strength properties.

- Aerospace: The process is used to create structural parts for aircraft that require precision and strength without adding unnecessary weight.

- Consumer Electronics: Aluminum die castings are found in laptops, smartphones, and other devices, where their thermal properties and sleek finishes are highly valued.

- Industrial Machinery: Manufacturers rely on die-cast aluminum parts for their reliability and resistance to harsh conditions.

Cost of Aluminum Die Casting

The cost of aluminum die casting can vary significantly based on several factors, including the complexity of the part, the volume of production, and the specific aluminum alloy used. Initial tooling costs can range from a few thousand dollars to much higher amounts for complex designs. However, once the tooling is established, the per-unit cost can be very low, making aluminum die casting an economical choice for high-volume production.

Conclusion

Aluminum die casting stands as a cornerstone of modern manufacturing, delivering an exceptional balance of efficiency, precision, and performance. As industries evolve and demand for lightweight, durable components increases, the significance of aluminum die casting will only grow. For those seeking a reliable partner in aluminum die casting, look no further than Align Manufacturing. Their expertise in this innovative process ensures high-quality results tailored to your specific needs.

Align Manufacturing recognizes the growing importance of aluminum die casting in today's evolving industries, where lightweight and durable components are increasingly crucial. As a trusted partner, Align Manufacturing leverages its expertise to deliver high-quality, custom-tailored aluminum die-castings that meet the unique demands of your specific applications.

FAQs

Extend the Life of Your Stainless Steel: A Maintenance Guide

Stainless steel is a versatile and durable material that has become a staple in both industrial and consumer applications. Whether used in kitchen appliances, architectural elements, or medical equipment, the aesthetic appeal and functionality of stainless steel make it a popular choice. However, to preserve its shine and integrity, proper maintenance is essential. .

This guide will explore the best practices for maintaining stainless steel, emphasizing the importance of regular care and the expertise offered by Align Manufacturing, a leading provider of stainless steel products and maintenance solutions.

Stainless steel is an iron alloy with a minimum of 10.5% chromium content by mass. This chromium forms a passive layer of chromium oxide on the surface, which prevents further surface corrosion and blocks corrosion from spreading into the metal’s internal structure. While stainless steel is known for its resistance to rust, it can still accumulate dirt, grime, and even undergo corrosion if not properly maintained.

| Type | Composition | Key Properties | Common Applications |

| 304 | 18% Cr, 8% Ni | Excellent corrosion resistance; good formability and weldability; non-magnetic | Kitchen equipment, chemical processing, architectural applications |

| 316 | 16% Cr, 10% Ni, 2% Mo | Superior corrosion resistance, especially against chlorides and marine environments; non-magnetic | Marine equipment, medical devices, chemical processing |

| 409 | 11% Cr | Good corrosion resistance; high-temperature tolerance; magnetic | Automotive exhaust systems, heat exchangers |

| 430 | 17% Cr | Good corrosion resistance; formability; magnetic | Appliance trims, kitchen utensils, decorative applications |

| 440C | 17% Cr, 1.1% C | High hardness and wear resistance; moderate corrosion resistance; magnetic | Cutting tools, bearings, surgical instruments |

Cr = Chromium, Ni = Nickel, Mo = Molybdenum, C = Carbon

Types of Corrosion

Galvanic Corrosion:

- Galvanic corrosion occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte (like saltwater or even just moisture).

- The more active metal (the anode) corrodes while the less active metal (the cathode) is protected.

Key Tip

Common Combinations to Avoid:

- Stainless Steel and Copper: Copper is more noble than many stainless steels, leading to accelerated corrosion of the stainless steel.

- Stainless Steel and Brass: Brass, containing copper, can also induce galvanic corrosion in stainless steel.

- Stainless Steel and Lead: Lead is more anodic than many stainless steels, increasing the risk of corrosion.

- Stainless Steel and Zinc: While zinc is often used for sacrificial protection, direct contact with certain stainless steels can lead to localized corrosion.

Minimizing Galvanic Corrosion:

- Isolate Dissimilar Metals: Whenever possible, physically separate dissimilar metals using insulating materials like plastic washers, gaskets, or coatings.

- Select Compatible Metals: Choose metals that are close together in the galvanic series to minimize the potential for significant galvanic corrosion.

- Consider Sacrificial Anodes: In some applications, using a more active metal (like zinc) as a sacrificial anode can protect the stainless steel from corrosion.

Design for Drainage: Ensure proper drainage to minimize the accumulation of moisture and electrolytes.

Crevice Corrosion:

- Crevice corrosion happens in confined spaces where moisture can become trapped.

- The trapped moisture becomes stagnant and oxygen-depleted, creating an environment where corrosion can thrive.

- Common locations:

- Under gaskets, washers, and fasteners

- Inside joints and seams

- Beneath stacked materials

- Prevention:

- Ensure proper drainage to prevent water accumulation.

- Regularly clean and inspect crevices.

- Use non-absorbent materials for gaskets and seals.

Pitting Corrosion:

- Pitting corrosion is characterized by the formation of small, localized pits or holes in the metal surface.

- It often occurs in the presence of chlorides (like saltwater) and acidic environments.

- Identification:

- Look for small, often inconspicuous, pits or holes in the surface.

- Prevention:

- Regularly clean and rinse the surface to remove chlorides and other contaminants.

- Use corrosion inhibitors in environments with high chloride concentrations.

Environmental Factors

- Humidity: High humidity increases the rate of corrosion by providing a constant source of moisture.

- Pollution: Industrial pollutants and airborne contaminants, such as sulfur dioxide and nitrogen oxides, can accelerate corrosion.

- Temperature Fluctuations: Rapid temperature changes can cause thermal stresses in the metal, leading to the formation of microcracks that can accelerate corrosion.

Chlorides, such as salt from de-icing chemicals or seawater, can break down stainless steel’s passive layer, accelerating corrosion. Acids and harsh chemicals also pose risks by stripping away the protective film. To maintain stainless steel’s integrity, avoid cleaners with chlorides, rinse surfaces regularly, and neutralize chemical residues promptly.

Effective Cleaners for Stainless Steel in Manufacturing

- E-NOX CLEAN

- A specialized cleaner for removing corrosion, stains, and surface contaminants from stainless steel. It is particularly effective for light corrosion caused by environmental factors.

- WD-40 Specialist Cleaner

- A multi-purpose cleaner that provides lubrication and corrosion protection. Commonly used to clean and protect stainless steel surfaces while adding a protective layer.

- Bar Keepers Friend

- A non-abrasive cleaner that effectively removes tough stains, grease, and mild corrosion from stainless steel.

- Sheila Shine

- A stainless steel polish and cleaner that restores shine while protecting against corrosion and fingerprints.

- 3M Stainless Steel Cleaner and Polish

- Designed to clean, polish, and protect stainless steel in one step. It prevents dirt and corrosion buildup.

- Simple Green Pro HD

- A heavy-duty degreaser and cleaner, effective on stainless steel machinery and equipment without causing damage to the surface.

- ZEP Stainless Steel Cleaner

- Formulated for industrial use to remove grease, grime, and stains, while protecting against corrosion.

- Blue Magic Metal Polish Cream

- Effective for restoring and maintaining stainless steel surfaces, particularly those exposed to harsh conditions.

- Flitz Stainless Steel Cleaner

- A biodegradable cleaner that removes oxidation and protects stainless steel surfaces from further corrosion.

- Stellar Solutions CitriSurf 77

- A citric acid-based passivation cleaner that enhances the formation of the chromium oxide layer, preventing corrosion on stainless steel surfaces.

Avoiding Installation Damage

Improper installation can compromise stainless steel’s protective layer.

Stainless steel is an alloy of carbon, iron, and chromium, designed for durability and rust resistance. During manufacturing, processes like polishing and passivation help form a thin chromium oxide layer. This “passive film” acts as a protective barrier, shielding the metal from rust. Remarkably, if this layer is scratched, it self-heals by regenerating when exposed to air, ensuring long-lasting protection

For example, using steel tools on stainless steel can deposit ferrous particles that interfere with the formation of the chromium oxide layer. Even minor scratches from screwdrivers or abrasions from iron equipment can dilute chromium at the surface, leading to rust. Post-installation cleaning is crucial to remove any contaminants and restore balance to the surface chemistry.

Polishing Stainless Steel

For that extra shine, you can polish stainless steel with products designed specifically for this purpose. Remember to polish in the direction of the grain and use a clean, soft cloth for application.

Outdoor Stainless Steel Maintenance

Outdoor stainless steel items are exposed to harsher conditions:

- Frequent Cleaning: Clean outdoor stainless steel more frequently to combat exposure to the elements.

- Protective Coatings: Consider applying a protective coating to outdoor stainless steel to guard against environmental damage.

- Inspection and Repair: Regularly inspect outdoor items for signs of rust or corrosion and address them promptly.

Outdoor stainless steel faces harsher conditions, such as salt, pollutants, and weather fluctuations, which can accelerate corrosion. Regular maintenance includes rinsing surfaces after rain or snow, inspecting for rust or staining, and applying protective coatings to enhance resistance. Adjust your cleaning schedule based on environmental stress—e.g., quarterly for high-salt areas or during seasons with heavy use of de-icing chemicals.

Key Tip: Conduct regular inspections, at least monthly, to identify any signs of corrosion, such as:

- Discoloration

- Rust spots

- Pits

- Cracks

- Staining

Conclusion

For more information on stainless steel maintenance, contact Align Manufacturing .Whether it’s addressing minor corrosion or maintaining large-scale installations, Align Manufacturing offers the tools and knowledge needed to preserve stainless steel’s shine and strength.

Here’s a concise table summarizing various types of stainless steel, highlighting their key properties and common applications:

For more on how to extend the lifespan of your stainless steel check out our guide here.

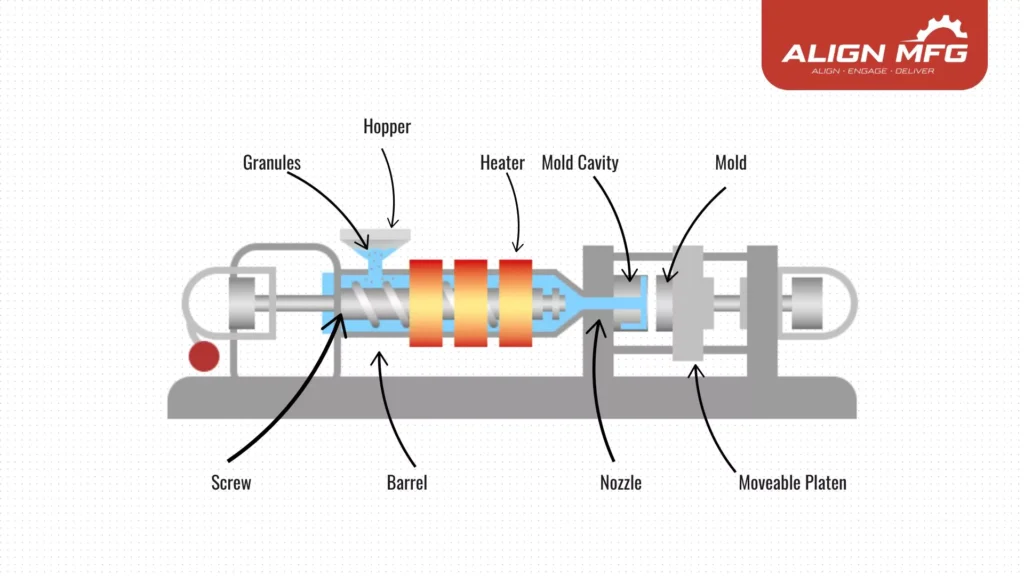

Plastic Injection Molding: Understanding the Process and Its Applications

Plastic is an indispensable part of our daily lives, shaping everything from simple household items to complex medical devices. In this blog post, we'll delve into the basics of plastic injection molding, how it works, and why it's such a crucial technique in modern manufacturing.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process used to produce large volumes of identical plastic parts. It involves melting plastic pellets and injecting the molten plastic into a mold under high pressure. Once the plastic cools and solidifies, the mold is opened to release the finished part. This process can be repeated multiple times with an incredibly high level of accuracy and speed, making it ideal for mass production.

Key Components of Plastic Injection Molding

The plastic injection molding process revolves around several key components:

The Injection Molding Machine

At the heart of the injection molding process is the injection molding machine, which consists of two primary components:

- The Injection Unit: This section is responsible for melting the plastic pellets and injecting the molten material into the mold. It features a hopper for feeding the pellets, a barrel for heating, and a screw mechanism that pushes the molten plastic into the mold.

- The Clamping Unit: This part secures the mold during the injection and cooling phases. It ensures that the mold remains tightly closed to prevent any leakage of the molten plastic, which is critical for maintaining the integrity of the final product.

The Mold

Molds are typically crafted from steel or aluminum and are custom-built for each specific project. They can be designed with multiple cavities, allowing for the simultaneous production of several parts in one cycle. The design of the mold is crucial, as it determines the shape, surface finish, and overall quality of the finished product.

| Part Name | Function | Details/Insights |